M700

Quick ViewView Full Details |

Motor Drive for Port and Freight Terminal Machinery Control Techniques drives are installed in ports around the world; they deliver superior performance, compact, modular and span a wide power range, making them an ideal solution for installation. Key benefits

|

M700

Quick ViewView Full Details |

Motor Drive for Stage & Enterainment Control Techniques Drive are installed in many of the most prestigious theatre and music venues around the world. Our drives have also been used in the making of many large professional sporting events like the Super Bowl as well as many Hollywood blockbuster films. Key Benefits

|

M200

Quick ViewView Full Details |

Motor Drive for Forestry and Woodworking Variable frequency drives from Control Techniques can utilize our high torque capability coupled with the ability to start and stop quickly to maximize operation time by minimizing the wait for transition periods, even when maintenance is required on the equipment. Key Benefits

|

M200/701

Quick ViewView Full Details |

Motor Drive for Heating, Ventilation and Air Conditioning (HVAC) Control Techniques is a world leader in variable speed drives and solutions. As part of Nidec Copal, a global leader in HVAC, we are well placed to help building owners, consultants, contractors and OEMs to maximize equipment efficiency and to keep pace with legislation and technology.

Key Benefits

|

M701

Quick ViewView Full Details |

Motor Drive for Lifts and Elevators Control Techniques is a leading supplier of drive technology to the elevator industry, with over 3 million elevators in operation with our control equipment worldwide. Backed by

our global network of Automation Centers we provide local expertise and support,

along with quick delivery of robust and dependable products.

Key Benefits

|

M200/701

Quick ViewView Full Details |

Motor Drive for Material Handling Material Handling is concerned with the transport and storage of materials. Drives from Control Techniques provide the power and control to move materials efficiently and safely. Key Benefits

|

M200/701

Quick ViewView Full Details |

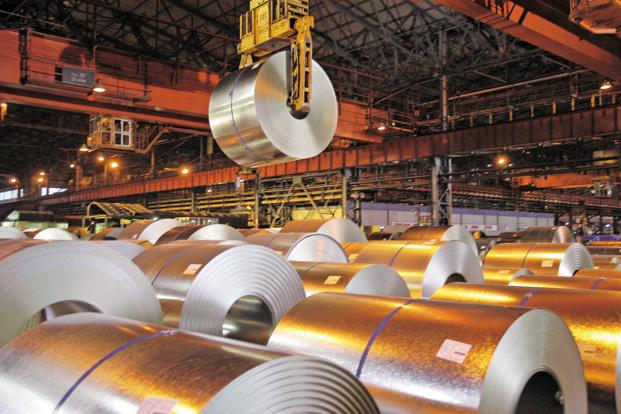

Motor Drive for Metal Industry Drive systems from Control Techniques can improve your process control to enhance finish quality, plant productivity and yield. Systems are engineered and supported globally through our Automation Centre network. Our engineers located around the world have in-depth process and application knowledge of metals manufacturing. Key Benefits

|

M200/701

Quick ViewView Full Details |

Motor Drive for Mining, Cement and Aggregate Control Techniques' drives offer the latest in digital technology to provide the ease of set-up and reliability needed in demanding applications.

Key Benefits

|

M200/701

Quick ViewView Full Details |

Motor Drive for Packaging Machinery Packaging machine builders face a variety of challenges, ranging from company and supplier issues to customer demands and competitive pressures.

Key Benefits

|

M701

Quick ViewView Full Details |

Motor Drive for Port and Freight Terminal Machinery Drives and control systems from Control Techniques are installed in port applications around the world. Our compact and flexible solutions provide the power and control to move materials efficiently and safely, our experience and expertise allows us to maximize the efficiency, speed and reliability of your cranes. Key benefits

|