Expert Vibro

Quick ViewView Full Details |

Portable vibrations measurement case Many service providers have established themselves in the field of vibration measurement technology and provide support in the analysis and rectification of vibration problems. The servicing department of major operations use their own specialists to carry out vibration analysis on machinery and plant. Vibration analysis requires meaningful measurement data acquired at the plant's location. Delphin's mobile measurement case for vibration measurement can acquire the signals from a range of different vibration sensors. Options are available for virtually every available type of connector on the market. Lemosa, BNC, Tuchel and specific sensor technology are generally used. Application features

Typical areas of application

|

LSB200

Quick ViewView Full Details |

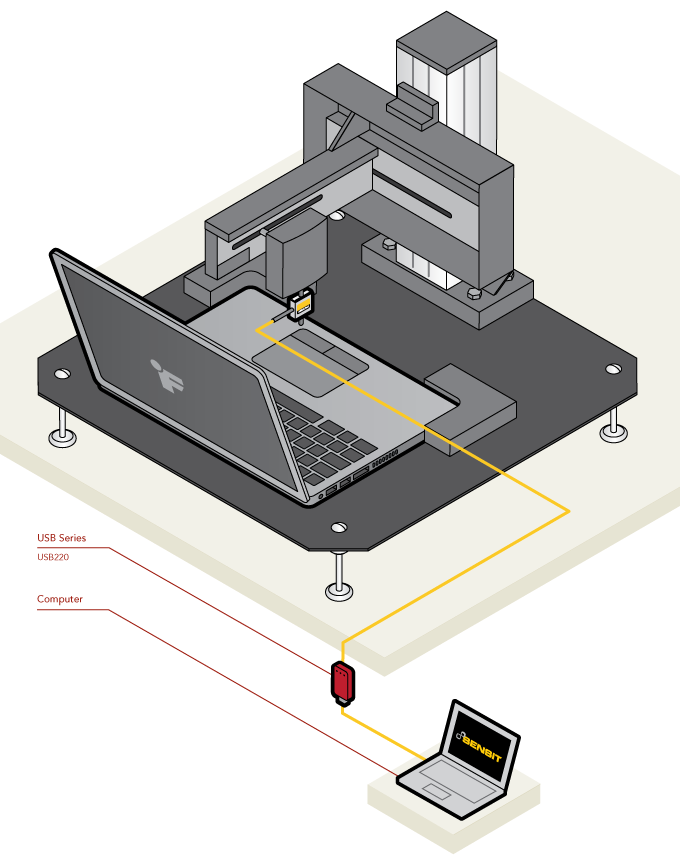

Application Summary A system is defined by its weakest link. Even something as small as the sensitivity of a trackpad is scrutinized to make sure it delivers optimal performance to the end user. In this application, FUTEK’s LSB200 is fixed onto a testing actuator to record tactile feedback, run cycle test and quantify the force required to stimulate touchpad response. Products in Use Jr. Miniature S-Beam Load Cell (LSB200) paired with Instrumentation (USB220). |

ATM/N

View Full Details |

Tank Gauging System Marine sea going vessle are installed with many tanks on board for maintaining trim and stability, it therefore need to be measures continuously its level, volume and temperature of the contents of ballast water, fresh water, cargo, fuel oil, bilge and mud tanks. Additionally, the vessel’s draught can be measured. High and low alarms also need to be control and alert whenever over the alarm limit. |

ATM/N

View Full Details |

Freshwater and wastewater tanks All sea going vessle require fresh water and waste water tanks for working crew on board, fresh or drinking water is either carried in special potable water tanks or obtained from seawater through a purification treatment. The collection, treatment and disposal of ship wastewater in internal storage systems must also be monitored using an appropriate technology. Since this wastewater is often contaminated with harmful substances, such as oils or cleaning agents, its processing also remains subject to certain additional requirements. Both freshwater and wastewater tank systems are checked and monitored using built-in sensors. In this way, the systems can be monitored most efficiently, which in turn guarantees an optimum water supply across the high seas. |

ATM/N

View Full Details |

Ballast tanks On board of all sea going vessle, Water ballast tanks are used to compensate for maintaining the trim and stability of the vessel for a safe sea passage. Ballast tanks are an important part of shipping. Without loading these tanks, large cargo ships can sometimes be too light, meaning that their propellers will not position deep enough in the water. To ensure a sufficient draught, the ballast tanks are filled up with seawater and can even be used to even out the weight distribution across a loaded ship. Since these tanks are being filled with saltwater, both the materials of the tanks and those of the sensors used must be robust and corrosion-resistant. Special attention is also paid to high reliability and durability, since the sensors are virtually inaccessible underway during on-board operation and must therefore function perfectly without any manual maintenance or inspection. |