Expert Logger

Quick ViewView Full Details |

Easy integrationAll household appliance are tested during outgoing quality controls for operation safety, energy efficiency, quality and reliability. Every country have Standards and test regulations that form the basis for many of the tasks involved in the testing. Testing for conformity to standards has a high potential for automation. ProfiSignal Klicks in combination with the Message and Expert Key devices are ideal for testing household appliances. Full galvanic isolation, flexible inputs and the easy to generate test procedures and sequences are the main factors that enable users to easily incorporate testing requirements for different household appliances. Application features

Typical areas of application

|

ProfiMessage

Quick ViewView Full Details |

Fast and flexible connection technologyThe testing of heating units and systems takes place according to a range of standards. Automation of testing procedures and test results are required but it involves lots of effort and is prone to error. However, the complex series of formula required for automation are simple to generate using ProfiSignal. Measurement data provides the basis for a product‘s technical specifications so the technology used needs to be capable of high-level precision. ProfiMessage and Expert Key devices are ideal for delivering the required levels of precision. A special feature within ProfiSignal is its dynamic reporting function. Reports can be opened using the ProfiSignal Viewer, printed and sent as PDF file. Application features

Typical areas of application

|

Expert Key

Quick ViewView Full Details |

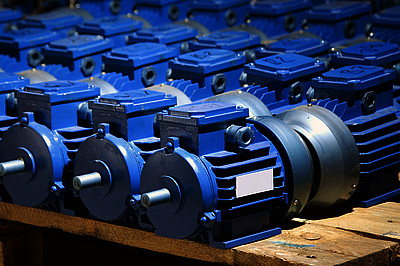

Precision electrical measurementMotor Test stands are required during the developmental phase, for production testing and for endurance trials. Measurements during the developmental phase are fully automated whenever possible. They check the electrical and mechanical properties of the test sample as well as temperature patterns and overload operation. Testing conditions can vary widely – from the tiniest of motors through to large drives in the megawatt range – and need to be adapted to customer requirements. The modular design of Message devices as well as the compact Expert Key devices, in conjunction with a tailor-made ProfiSignal application, provide an inexpensive, fully automated solution. Application features

Typical areas of application

|

Expert Key

Quick ViewView Full Details |

Fast acquisition of velocitiesPumps are required in a diverse applications ranging from micro-dosage pumps in chemistry labs and standard pumps for gardens through to large-scale industrial or vacuum pumps. Each application has differing testing requirements. Users from the pump sector enjoy the flexibility and universal inputs of the Message and Expert key devices. Adjustable sampling rates of up to 100 kHz enable users to perform high-resolution inspections and testing. The hardware’s dependability and the continuous, long-term archiving of data via the ProfiSignal software makes them ideal for service-life testing, environmental simulation and endurance testing. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

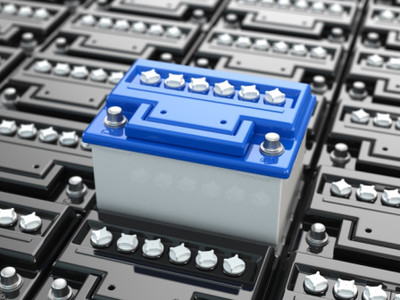

The future is battery-powered. But are we overcharging the planet? Storing large amounts of energy is still a young field, it presents challenges, especially safety. Testing energy storage capacities of batteries, rechargeable and fuel cells is a current issue. Battery Test stand are being used in the R&D sections. Delphin Message devices are ideal for such applications due to high galvanic isolation between channels. Avoiding any possibility of short circuits between batteries cells. The devices operate independently and their monitoring functions make them ideal for the high energy densities involved in the testing of batteries and fuel cells. The hardware devices combine perfectly with the ProfiSignal Go software for measurement data evaluation, and with the ProfiSignal Klicks software for automation. Application features

Typical areas of application

|

Expert Key

Quick ViewView Full Details |

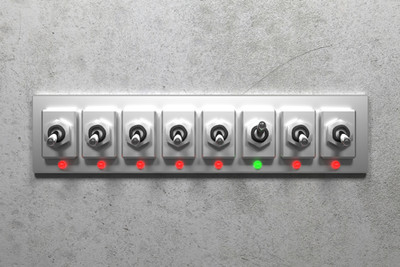

Reliability during testingSwitches ranging from micro to power switches for medium-voltage networks undergo testing according to different types of norms and standards. Tests are performed according to switching points, bounces and switch opening/ closing delays. The Expert Key and Message devices with their high-speed analog and digital inputs provide the necessary hardware. Switch data is precision recorded and stored along with time-stamps. Delay times for opening/ closing/ switching are accurately determined and can be computed and portrayed using software channels during the actual testing. Logic diagrams within the ProfiSignal software portray test samples clearly as different tracks. Contact bounce and other errors are quick to identify and undergo recording and numbering. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

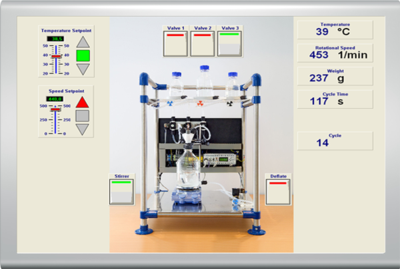

Data acquisition, control and evaluationValves are manufactured in a range of sizes, materials and versions. Different standardized testing requirements are necessary depending on the branch in which the valves are to be used. Valves undergo testing during both developmental and production phases as well as for quality assurance and actual use, e.g. cyclical functional testing of rapid closing safety valves in steam turbines. By using a ProfiSignal automated testing and evaluation system, reproducible and significantly faster measurement and evaluation procedures can take place. The flexibility of Expert and Message devices enables a hardware system to be selected that exactly meets testing requirements. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

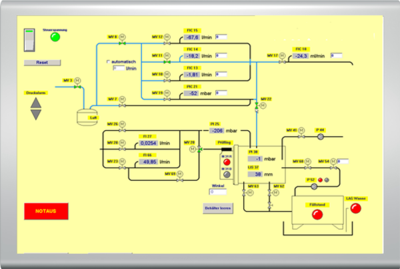

Programming by selectionProcess control systems are used primarily in laboratories, at universities and in industrial research and development departments. Typical applications include using temperature profiles for the testing of household appliances. Laboratory users require a high level of flexibility and high-speed response times. This therefore excludes using conventional PLC systems. By using the Klicks intuitive programming language and "sequencer" module, users can create process control programs without having to learn a programming language. A laboratory engineer is then able to automate his or her own experiments. The created process program is easy to comprehend, amend and maintain. The Delphin hardware is equipped with measurement inputs as well as analog and digital outputs. Application features

Typical areas of application

|

Expert Logger

Quick ViewView Full Details |

Data security and monitoringThe aim of endurance testing is to subject products to long-term testing and to provide service life certification. The basis for a PC-independent system of long-term data acquisition and control are hardware devices equipped with 16 GB internal memories and independently operating control and regulating functions. Such devices function operate continuously and restart automatically in the event of a power failure thereby providing uninterrupted data recording. Faults and system failures can be reported via email or switch outputs. An integrated scheduler within the DataService system enables additional data archiving to a PC or server. Users can then use ProfiSignal from any PC to evaluate archived data. Application features

Typical areas of application

|

Expert Key

Quick ViewView Full Details |

Component testing The testing of individual components has become essential due to product liability legislation. Components are expected to be reliable and to have long service lives, and costly returns and recalls need to be avoided. Expert Key and Message hardware devices along with ProfiSignal software are therefore being used in a range of sectors for component testing. Customers benefit from the high levels of flexibility and reliability that Delphin products offer. For special testing procedures, Delphin offers inexpensive systems that can be tailored to specific testing requirements. Application features

Typical areas of application

|