Powder Coating Acid Liquid Level Sensor |

|||

|

|||

|

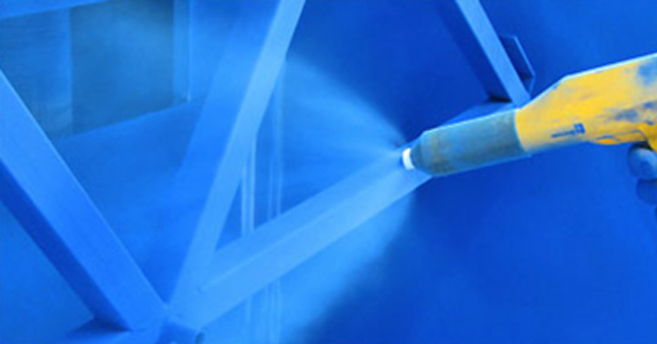

This is achieved in multiple stages consisting of degreasing, etching, de-smutting and the final phosphating of the substrate with phosphoric acid to enhance the bonding strength of the metal surface. Based on the parts finish requirements and size, diluted acid is applied by either dipping or spraying. Once rinsed and dried off, the clean parts are ready for powder coating and the oven. At this US defense contractor, an EchoPod ultrasonic level transmitter is installed in each of their phosphoric acid day tanks that are located near the ceiling to maximize floor space. The non-contact, corrosion resistant sensor was selected because of it’s industry leading 2″ dead band that enables near full capacity utilization of small tanks. Flowline is reliable level measurement. |

|||