|

|

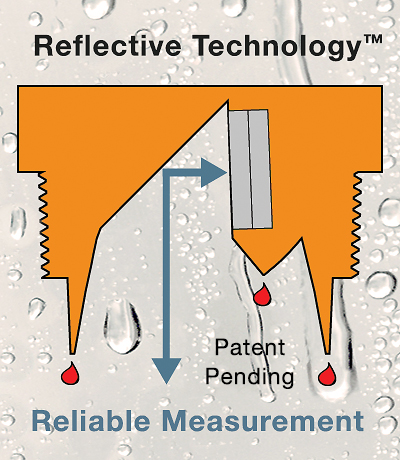

When a Michigan manufacturer of air solenoid valves needed reliable level measurement of their water storage tanks, they turned to Flowline. The company plates or paints their valve components and hot water is supplied to both processes through insulated bulk tanks. Heated to 100º F., the storage tanks are dripping with condensation that caused their previous ultrasonic level sensors to function erratically due to acoustic signal attenuation. For this reason, Flowline suggested the use of our reflective ultrasonic liquid level sensors that work in condensation. The ultrasonic sensors provide reliable level data to the controller, which in turn, monitors the water inventory and periodically refills the tank from the boiler. Flowline is reliable level measurement.

.

|