|

|

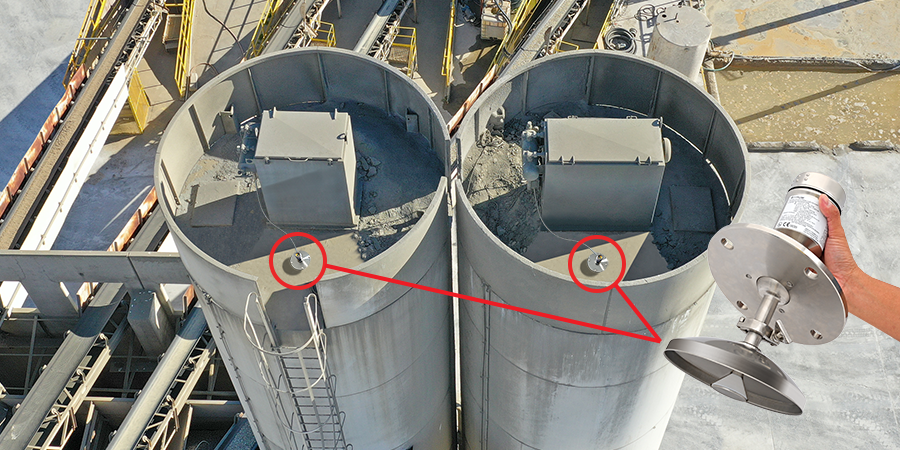

When a Minnesota concrete mix plant needed reliable level measurement of their cement silos, they turned to Flowline. The firm crushes, batches, mixes and delivers wet concrete to contractor sites throughout greater Minneapolis. A concrete batch is comprised of 40% gravel, 30% sand, 20% water and 10% cement or the binding agent that glues everything together. Cement powder is periodically delivered and stored in silos. There the operators were dissatisfied with previous mechanical type level sensors that often clogged with powder and hardened cement fragments that had reacted with condensation. For this reason, Flowline suggested our non-contact radar sensors with high power antennas that are unaffected by buildup. The radar sensors provide reliable level data to the PLC, which monitors the cement silos, and alarms for replenishment. Flowline is reliable level measurement.

|