|

|

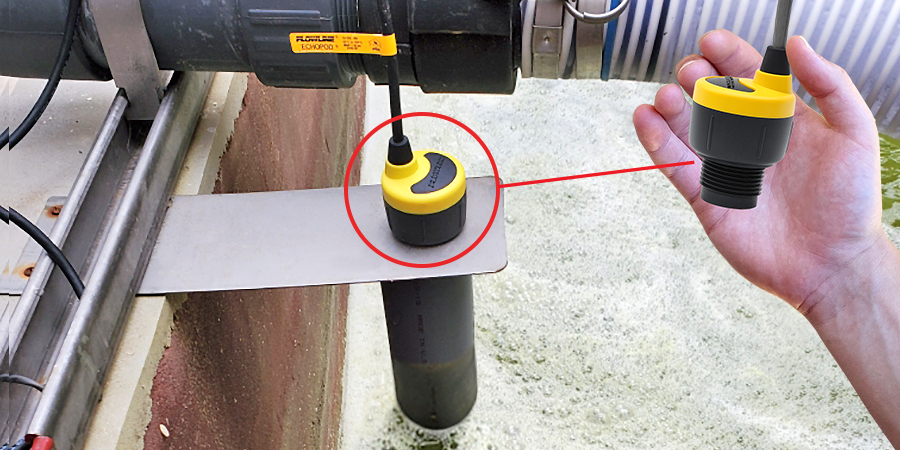

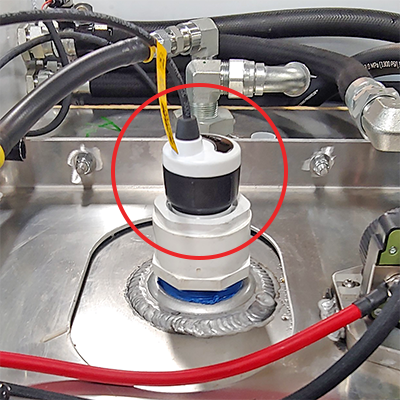

When US manufacturers need reliable non-contact level measurement of their foaming small tank skid or machine systems, they turn to Flowline. Foam is sometimes created by mixer and pump processes. Foam attenuates acoustic energy and may cause ultrasonic level sensors to function erratically. But the benefits of non-contact measurement and cost are often still desirable. Where so, the solution is to install your ultrasonic sensor in a standpipe, which separates the measurement from foam or agitation for a reliable, stable output. Despite the foam, The ultrasonic sensor provides reliable level data to the machine or skid PLC. Flowline is reliable level measurement.

|