Construction industry, building materials |

This area means less the construction industry directly but rather the suppliers of the construction companies and also manufacturers of building materials. Modern buildings have high requirements which can only be achieved by means of high quality building materials. Therefore, the quality must be already measured during the production of building materials using distance and position sensors. The measuring technology of Micro-Epsilon has already proven itself many times for this use. |

Asphalt mixing systems - temperature measurement For temperature measurements in asphalt mixing systems, both the temperature of the mineral discharge and the temperature after mixing are measured. Infrared sensors from Micro-Epsilon are used for this which still operate reliably even under adverse environmental conditions. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Automatic height adjustment for material analysis Laser-induced breakdown spectroscopy (LIBS) performs precise analysis of the atomic composition of different materials. The measurement objects involved are mostly mineral or metallic parts whose surfaces have different gloss levels and which are sometimes extremely tilted. SECOPTA analytics GmbH uses the ILD1320-100 sensors from Micro-Epsilon in this application to automatically readjust the height of the LIBS sensor head. Particularly with metal samples whose surfaces have different textures such as oxidized spots, the ILD1320 with the ATC feature is a reliable sensor. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Building materials – temperature measurement Micro-Epsilon temperature sensors are always used for the manufacture of construction materials when the monitoring and control of the temperature are critical for the product quality and productivity. The most important application areas are the cement industry, the production of plasterboard sheets and the pretensioning of architectural glass. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Determination of the thermal conductivity of building materials An important criterion for the quality of porous concrete is the thermal conductivity. It varies in the final product due to quality differences in the raw materials used (including sand and natural lime). An internal determination of the thermal conductivity using a double-plate device as in DIN 52612 Part 1 immediately after production enables a substantially faster reaction in comparison to the previous external testing of samples. The double-plate device available to the user was equipped with a computer system with application-specific evaluation software. The software was developed with the modular software toolbox ICONNECT. |

| __________________________________________________________________________________________________________ |

Measuring the height of concrete blocks For the final inspection during the production of concrete blocks, a special test bench records the height of the blocks over a number of tracks. On each track, an optoNCDT 1700 laser sensor measure vertically on the conveyor belt. The blocks on the conveyor belt run through the sensor's laser beam. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Lift height measurement for maintenance work on bridges In certain cases for maintenance work on bridges, the bridge must be raised, for example to replace the supports. Heavy-duty jacks are used for this. The distance at each jack is measured with a draw-wire sensor so that the jacks operate completely in synchronization. Sensor technology applied |

| __________________________________________________________________________________________________________ |

3D inspection and surface assessment of roof tiles The production of roof tiles places high demands on measurement and testing methods for ensuring constant high product quality. In the DASTOKON semi-automatic measurement and test system and in the BSPK pilot plant a laser triangulation sensor of the Series ILD 1800 is used for the 3D inspection and for surface assessment. Sensor technology applied |

Defect recognition on worktops Kitchen worktops are now made from a variety of materials, e.g. natural or artificial stone, solid wood and laminate (e.g. HPL). All these materials offer benefits and have special characteristics. However, a defect-free surface finish and perfect edges are critical production factors. The example above is a so-called laminate worktop with a stone decor. As the cutting edge of this top is rough and unclear, it is covered with sidebars. Foreign bodies, uneven distribution of the adhesive or unevenness when closing may produce open joints between the top material and the sidebars. The scanCONTROL 2910-25 laser profile scanner is used to inspect if any open joints are present. Sensor technology applied |

| __________________________________________________________________________________________________________ |

In-line detection of protective film on PVC window frames Company „Schüco“ manufactures PVC window frames. The PVC profiles are provided with a protective film after they are extruded. This film protects the frames from scratches and dirt. The colorCONTROL ACS7000 color measurement system checks if the protective film has been applied correctly. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Color detection of kitchen fronts Kitchens are available in many different colors. In order to guarantee that the customer receives the desired color, the colorSENSOR OT-3-MA-30-16 inspects the color of the kitchen fronts in the painting plant. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Color measurement of the floorboards Plastic floorboards are made of colored granules and shaped by deep-drawing. After the production process, it must be guaranteed that the color of the floorboards is homogenous and that there are no color differences. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Plaster hardening - temperature measurement Stationary Micro-Epsilon temperature sensors are used for optimization of the additives during plaster hardening. Due to the constant temperature monitoring of the hardening reaction, defects can be detected immediately and thus sustainably increase the quality. Sensor technology applied |

| __________________________________________________________________________________________________________ |

On-line inspection of the dimensions of sand-lime bricks After pressing the sand-lime brick blanks are placed onto a hardening carriage. Even smallest changes in the mixture, moisture, or in the pressing force lead to undefined growth of the bricks and make it difficult to observe the required brick height. A non-contacting laser-optical measuring system with down-stream evaluation logic is installed above the conveyor belt. This system measures the brick height and allows automatic signalling and sorting of the products that exceed the upper or lower tolerance limits. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Exact crusher gap adjustment in rotary crushers Rotary crushers for quarries or ore mines can grind up to 3500 t of material to the desired grain size in one hour. For this purpose an eccentric bearing bush generates a rotary-oscillating movement of the crusher axle, thereby constantly changing the gap between the crusher jaws and the crushing cone. For grinding the set gap continuously moves along the inside perimeter of the crushing room. With a longdistance sensor in the hydraulic cylinder the crushing gap can be exactly adjusted by raising and lowering the axle. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Glued wood - temperature measurement After drying and sorting the wood laminates, they are cut to the required length, glued, stacked and pressed afterwards. They are heated using microwaves for the glue drying and the individual glue layers are measured with a very small infrared spot size. The extremely small measuring spot diameter of the Micro-Epsilon thermometers makes friction-free measurement possible. Sensor technology applied |

| __________________________________________________________________________________________________________ |

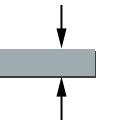

Thickness measurement using displacement sensors Thickness measurement using displacement sensors is a wide application area. Basically there are distinctions between non-destructive/destructive, non-contact/with contact and one-side/two-sided thickness measurement. The Micro-Epsilon measuring techniques for thickness measurement are all emission-free whereby no emissions regulations of any kind have to be complied with. Thickness measurements must be performed both with contacting as well as with non-contact sensors whereby non-contact measuring techniques show advantages as regards accuracy and measuring speed. There is also a distinction between one-sided and two-sided thickness measurement. Two-sided thickness measurements are carried out with at least one pair of sensors which are installed together on one axis. This pair of sensors measures the target synchronously. The difference between the measurement results (C-A-B) produces the thickness of the measuring object. One-sided thickness measurements must only be performed with non-contact sensors. In doing so, the target is only measured with one sensor and either only a part of the target thickness (e.g. layer thickness) or the complete measuring object thickness is measured. Thickness measurements are mainly used in process control and quality assurance, e.g. for the control of extrusion systems or 100% checking of tube diameters. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Automated board measurements in wood production Electronic Wood Systems GmbH (EWS) has launched the "dimension scan"a new approach to the automated measurement of finished boards. The market leader in measurement systems for the wood processing industry, based in the German town of Hamelin, EWS developed this innovative solution for the inline quality control of chipboards, MDF and HDF boards. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of the radial deviation of a cutter disk Sensor technology applied |

| __________________________________________________________________________________________________________ |

3D profile measurement of soil samples German automation company Visutronik GmbH from Neubrandenburg, Germany has developed a laser scanningdevice to measure surface soil samples for subsequent geometric analysis: roughness, surface type expansion (e.g. earthworm courses), etc. The core of the measuring device is the scanCONTROL 2700-100 laser scanner. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Damage prevention during production of locking cylinder The company Aumat (Germany) develops and produces complex production systems for locking cylinders. In order to prevent any damage occurring, the operator must feed the correct blank into the production programme of the control system. This safety measure requires that a high number of components are detected and identified clearly and reliably in terms of both length and color. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Filling level A filling level measurement situation can arise with a liquid substance as well as with dry, bulky goods. The precise measurement of liquid levels is difficult to achieve, nevertheless, the confocal measuring technique is a suitable solution for this problem. Light is also reflected on the surface of liquids and thus provides a reliable result. Filling levels of dry bulk materials are easier to measure due to the surfaces. The ILR Time-of-Flight sensors are suitable for deep containers. Laser sensors from the optoNCDT group are available for shorter sections. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Dimensional accuracy of sectional doors With sectional doors for parquet or laminate flooring, key and slot joints for individual sections are applied. However, these sections are opened and closed frequently. To enable a robust but permanent flexible key and slot joint, specified dimensions are critical and must be adhered to. This is particularly important in the case of significant temperature differences or inaccurate dimensions, where the door could be locked or positioned incorrectly. The measurement of the key and slot joint is therefore critical in ensuring the correct manufacturing dimensions. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of pre-stressed steel An inspection system for incoming goods inspection has been developed for a manufacturer of pre-stressed concrete, which detects the profile depth of delivered batches and continuously records this information to a database. Sensor technology applied |

| __________________________________________________________________________________________________________ |

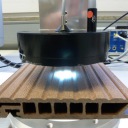

Non-contact roller measuring deviceIn the cement and mineral industry roller mills are used for fine grinding of the raw materials. During the milling process the rollers are subject to high wear, which strongly reduces the quality of milling at the edges of the rollers. With a laser-optical roller measuring device the necessary regrinding process can be initiated at the right time, and the success of such regrinding can be determined. A protective device with special damping elements and air nozzles protects the laser-optics sensor against vibrations, and keeps the optical system and the beam path free of dust. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Flatness inspection on ceramic wall tiles In the production of ceramic wall tiles or similar products, a one hundred percent quality inspection is essential. Three laser triangulation displacement sensors measure the deflection of tiles with an accuracy of 0.1 μm. Separate specification values can be entered for concave or convex deflections. Sensor technology applied |