|

|

|

Aerospace

|

|

In aviation, the highest requirements are placed on installed components in terms of safety and reliability. This especially applies to sensors which are used in different places. For example in aircraft assembly, sensors from Micro-Epsilon ensure non-contact rivet hole measurement. Micro-Epsilon develops displacement and position sensors for aircraft measurement tasks landing gear, wing assembly, fuselage and engines, where they enable reliable determination of measurement values. |

|

|

Non-contact inspection of rivet bore holes

|

|

In aircraft construction, several hundred thousand rivets are usually used. Fully automatic machines are precisely fitting rivet holes and rivets. An optical inspection system from Micro-Epsilon inspects the inside diameter of the rivet holes without contact.

|

|

|

|

Brake temperature measurement

|

|

Before an airplane can start, the temperature in the brakes must be below a certain limit. To determine the temperature, non-contact temperature sensors from Micro-Epsilon are used in the landing gear.

Infrared pyrometers for universal measurements Infrared pyrometers for universal measurements

|

|

|

|

Door lock detection

|

|

|

|

|

Reliable position recognition of the Wing-Tip-Brake

|

|

|

|

|

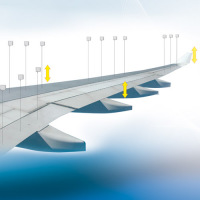

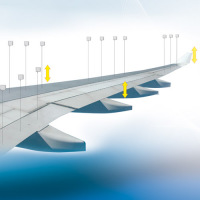

Load tests on airplane wings

|

|

In order to optimize the behavior of wings during a flight, the wings are already subjected to vibration tests during the construction. 120 wireSENSOR draw-wire sensors are connected to the wing and synchronized. In this way, any change of the wing form in the vertical direction can be tracked.

Draw-wire displacement sensors Draw-wire displacement sensors

|

|

|

|

|

|