|

|

|

Metrology and testing technology

|

|

In measuring and testing machines, the measurement technology used is the central element. Therefore, metrological parameters such as resolution and linearity are decisive factors in order to enable precise data collection. For operation in measuring and testing machines, Micro-Epsilon offers numerous measuring techniques based on highest accuracy. |

|

|

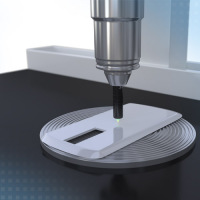

Coordinate measuring machine

|

|

In order to measure a wide variety of components, coordinate measuring machines are used. Different gauges and measuring devices provide a 3D image of the surface component. scanCONTROL laser line scanners are ideally suitable for this purpose. Based on the triangulation principle, they measure the actual component surface without contact to micrometer accuracy.

Confocal chromatic sensors for displacement, distance, position, thickness Confocal chromatic sensors for displacement, distance, position, thickness

|

|

|

|

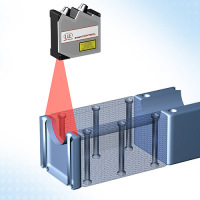

Calibrating robot axes

|

|

Industrial robots have become indispensable in modern production facilities due to their reliability and high speed. During set up and also at regular intervals within the scope of quality assurance, the robot axes must be adjusted. Here, electronic adjustment probes have already replaced mechanical probes. The measurement probes mounted on the robot axes acquire the zero point during the axis rotation using a probe tip. The integral electronics evaluates the probe signal and transmits a switching signal to the robot controller.

induSENSOR LVDT gages DTA series induSENSOR LVDT gages DTA series

Inductive sensors (LVDT) and gauges Inductive sensors (LVDT) and gauges

|

|

|

|

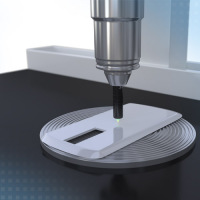

Coordinate measuring machine

|

|

Coordinate measurement machines from Zeiss have been known for decades for the highest quality, precision and reliability. Also the mobile measurement machine, ScanMax fulfills these criteria, in part due to the application of inductive displacement sensors from Micro-Epsilon.

Inductive sensors (LVDT) and gauges Inductive sensors (LVDT) and gauges

|

|

|

|

3D inspection and surface assessment of roof tiles

|

|

The production of roof tiles places high demands on measurement and testing methods for ensuring constant high product quality. In the DASTOKON semi-automatic measurement and test system and in the BSPK pilot plant a laser triangulation sensor of the Series ILD 1800 is used for the 3D inspection and for surface assessment.

optoNCDT Laser Sensoren optoNCDT Laser Sensoren

|

|

|

|

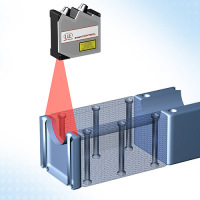

Coordinate measuring machine

|

|

Coordinate measurement machines are used for measuring many different components. Different scanners and measuring equipment measure the surface of the component in three dimensions. Laser line scanners are ideally suited for this purpose. They measure the actual surface of the component without contact and with micrometre precision according to the triangulation principle.

Laser scanners for 2D/3D profile measurements Laser scanners for 2D/3D profile measurements

|

|

|

|

|

|