|

|||||||||

What is the measuring principle of interferoMETER? |

|||||||||

|

|||||||||

|

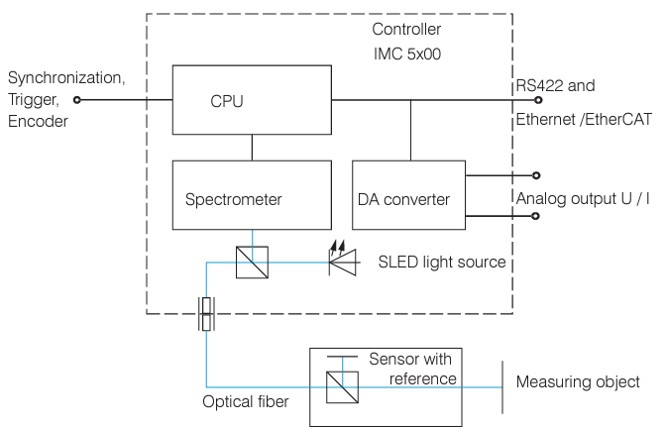

This is followed by the spectral decomposition and radiation of the detector. The light reflected by both the reference object and the measurement object overlaps. The interferometric measuring principle (superposition of waves) is used. Detection of distances and thicknesses is possible with amplification and elimination.

With a sensor for thickness measurement, the reference is omitted. This is why no distance measurement is possible.

Sensor and controller are one unit, as the sensor’s linearization table is stored in the controller.

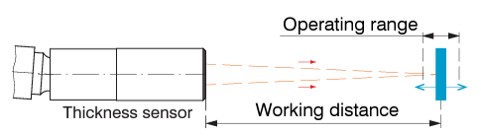

This unique measuring system allows for highly precise measurement of targets. It is possible to measure both diffuse and reflecting surfaces. For transparent layer materials, thickness measurements can be conducted in addition to distance measurements. Shadowing is avoided because sender and receiver are aligned along one axis.

The excellent resolution and the small beam spot diameter make it possible to measure surface structures. However, measurement deviations may occur if the structure is of a similar size to the beam spot diameter or if the maximum tilt angle is exceeded (e.g., with groove edges). |

|||||||||

Term Definitions |

|||||||||

|

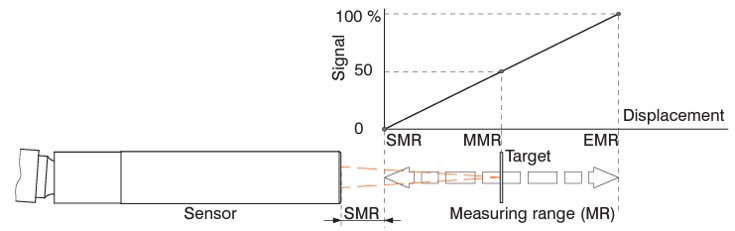

SMR - Start of measuring range. Minimum distance between sensor surface and target MMR - Mid of measuring range (=start of measuring range + 0.5*measuring range) EMR - End of measuring range (=start of measuring range + measuring range) - Maximum distance between sensor face and target MR - Measuring range |

|||||||||

|

|||||||||