|

|

|

PS6000 Series Features |

A New Experience for Automation Engineers from system design to commissioning |

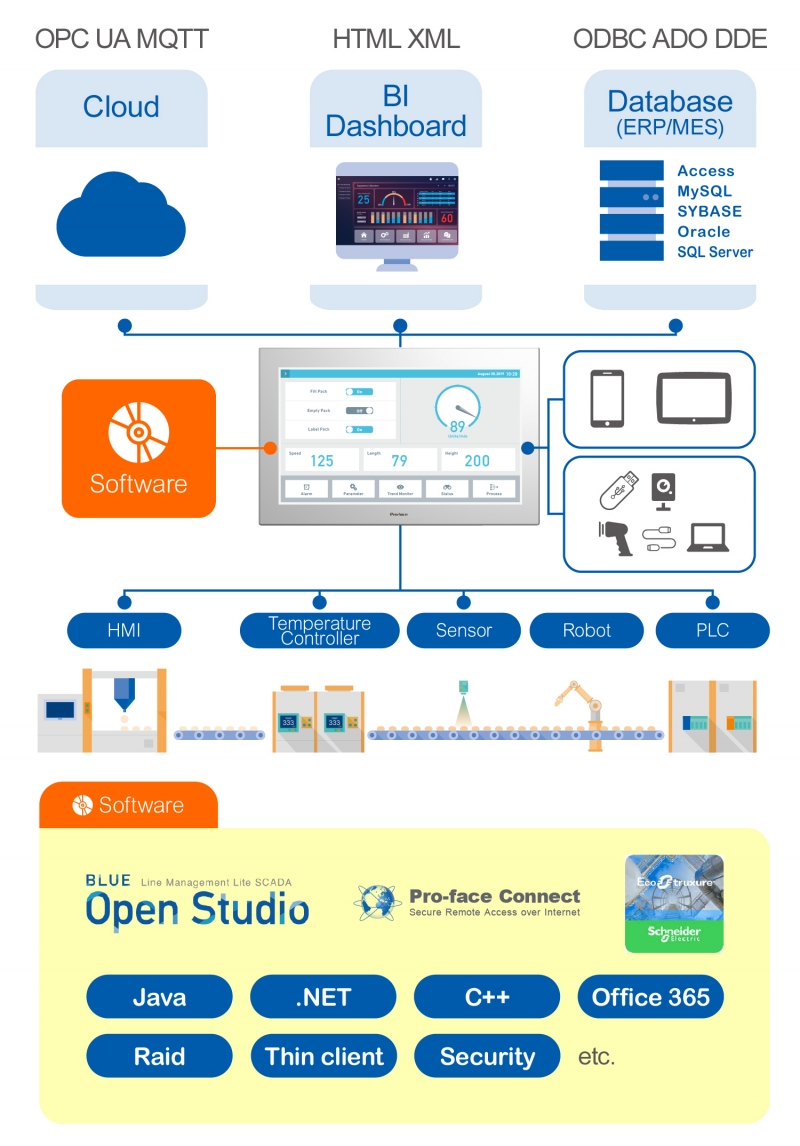

To run any software

To run any software and any type of use case for any architecture need. |

|

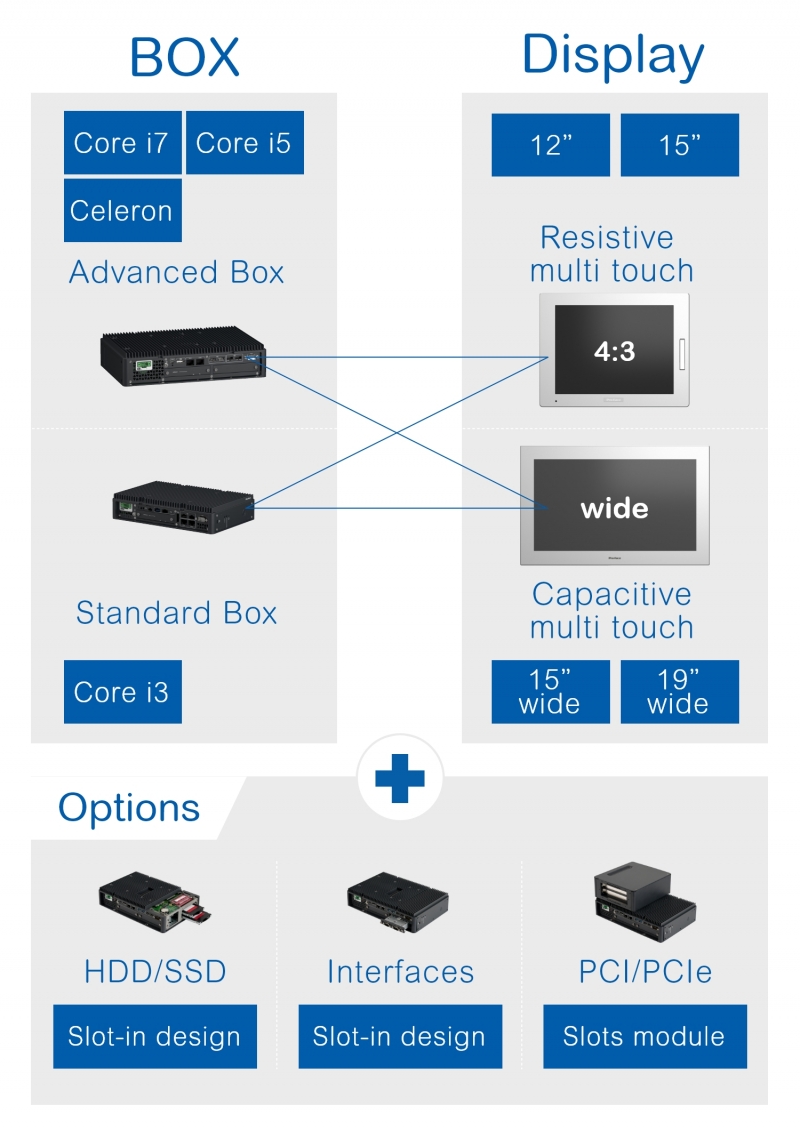

A rich modular catalog

From a rich modular catalog, easy change modules to flexible meet various needs. |

|

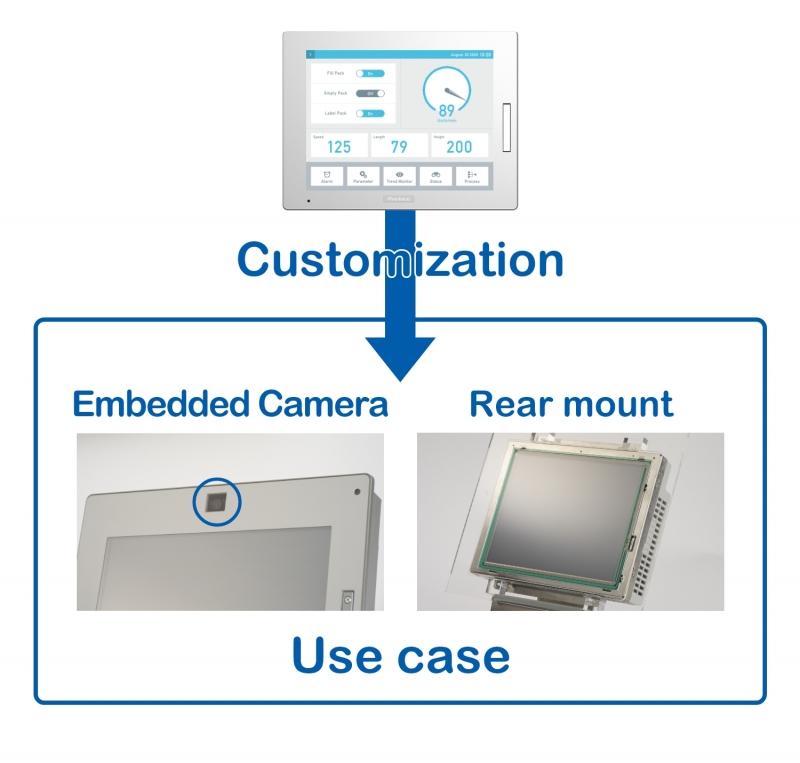

Strong background of customization service

Strong background of Pro-face for HMI customization service, to fit specific customer needs. |

|

Effortless developmentEffortless development with various HMI Specialist services & support.

|

|

Best in class pre-installed bundleBest in class pre-installed* bundle to improve your business with easy select and quick deliver.

|

|

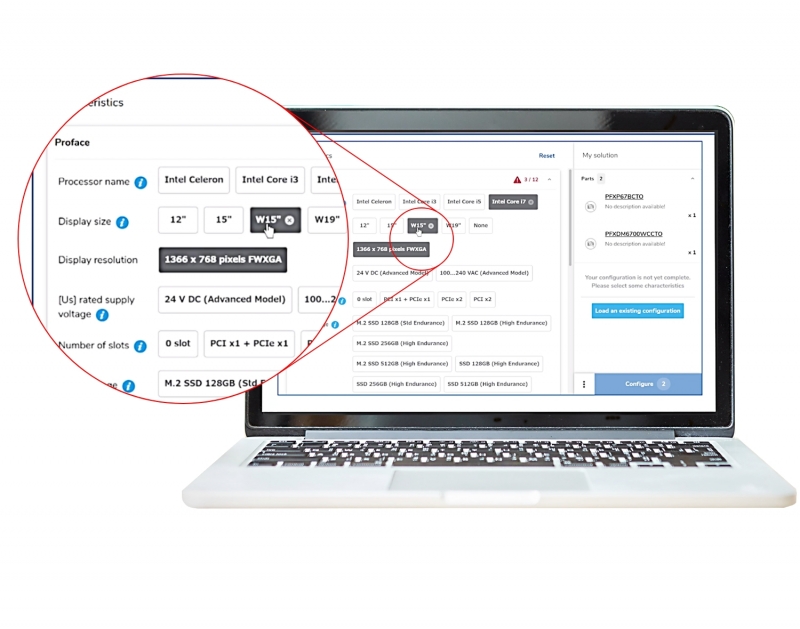

Easily selected with Product Configurator

Rich options, easily selected with new on-line configurator with quick delivery. |

|

A New Experience for Operators and Production Managers |

UI design and integrate application from a leader in HMI software

Integrated applications from a leader in HMI software with BLUE Open Studio.

etc... |

|

Tailored visualizationTailored visualization per user’s needs using Business Intelligence Dashboards. Integrated applications from a leader in HMI software with BLUE Open Studio. |

|

Performing but economical

High-performance with the latest CPU and display for smart manufacturing. |

|

Innovative displaysInnovative displays to flexible change the touch mode. Quickly change display type for operators situation with configuration. |

|

To run on most demanding industrial environments

Designed and certified to run on most demanding industrial environments.

|

|

Secure systemSchneider Electric is following an SDL (Secure Development Lifecycle) process compliant with the IEC62443 standard. PS6000 was designed accordingly to this IEC62443 standard. |

|

A New Experience for Maintenance Specialists |

Easy remote maintenance

Easy remote maintenance, measure downtime in hours, not days. |

|

Smart maintenance

Smart maintenance to reduce downtime and improve productivity.

|

|

Long Term Peace of Mind

Long Term Peace of Mind thanks to long availability, global support, and training.

|

|

Easy legacy migration

Easy legacy migration from PS5000 Industrial PC. |

|