Checking The Growth of Trees with LVDT Displacement Sensors

APPLICATION: 10mm measuring range of LVDT probes were used in this application. While Solartron LVDT displacement sensors possess the high resolution, thus the growth of the trees per minute can be known. IP65 avoid the water ingression from the rain to the probes, and with long cable lengths, the computer for data logging can be put in the shelter under the trees. With free downloadable software Orbit GCS, the data of the growth of the trees with time stamping can be logged into excel file.

|

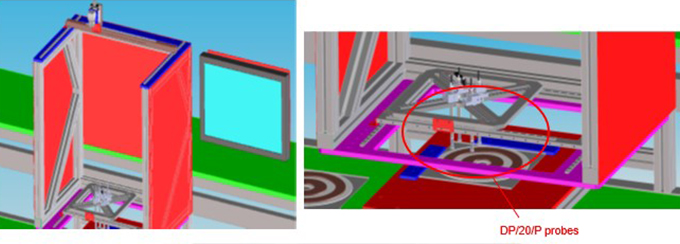

Checking Flatness and Thickness of Coil of Induction Cooker

APPLICATION: Solartron probe, the high precision and accuracy LVDT probe, did an excellent job in the checking of flatness and thickness of coil of induction cooker.

SOLUTION: DP/20/P probes with pneumatic actuation were used in this application. 4 probes were used in this application, and the difference of reading of probes were calculated to determine the flatness of the coil. The simple mathematic formulas are included in free downloadable software Orbit GCS, thus it benefited the end users when it come to the flatness checking.

|

Measure The Inner Diameter of Transmission Gear and Ring

APPLICATION: Customer want to measure the inner diameter of transmission gear and ring.

SOLUTION: Solartron probe was hid inside the WiGauge, and inner diameter was measured by Solartron probe through the mechanical transmission of plug gauge. There is a pass/fail indicator on the WiGauge and data would be transmitted wirelessly to PC for data logging.

|

Checking Blade Profile of Ice Skates

APPLICATION: Solartron probe, the high precision and accuracy LVDT probe, did an excellent job in the checking of blade profile of ice skates.

SOLUTION: LVDT probe was run along bottom of blade. Very precise tolerance with high required resolution. Linear Encoder was used to measure the position of LVDT probe. Measurement was taken at every mm of probe position. Solartron Orbit Network synchronized the readings of linear encoder and LVDT probe, thus profile of blade can be plotted out.

|

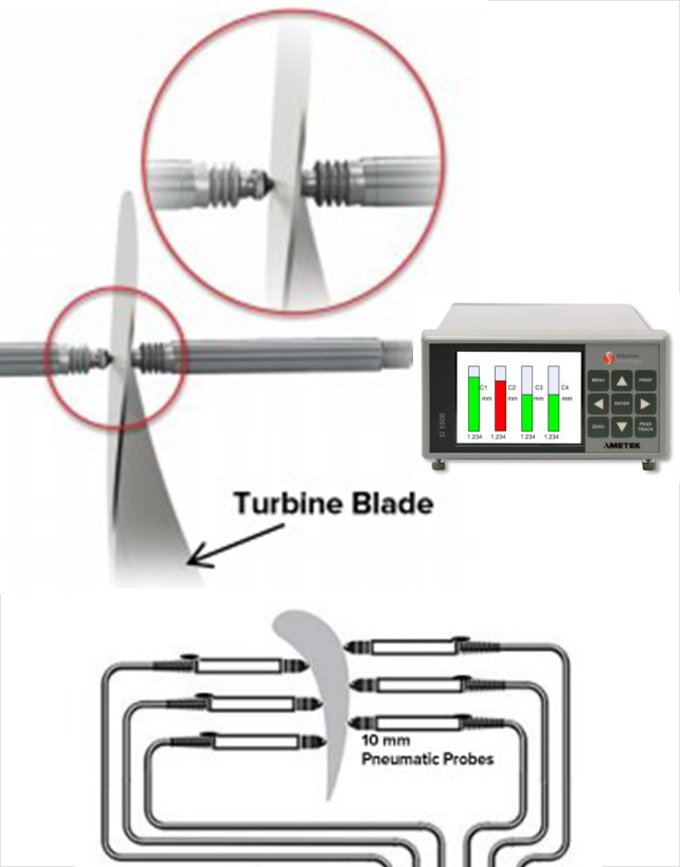

Measure Dimension of Turbine Blades

APPLICATION: Turbine blade is made by casting, following by surface grinding process. The dimensions of the blade post-grind need to be accurately measured as the initial proportions from the casting will have changed slightly.

SOLUTION: Using the Digital Probes (DP), the dimension of the turbine blades can be known. The measurement from the desired locations on the turbine can be taken, and fed into digital readout(SI5500). The measurement data from SI5500 is transmitted to PC that running a statistical process control(SPC) system. This data is then used to monitor the performance of the grinding process and quality of the finished parts, providing traceability records from the start of the process to the finished part. |

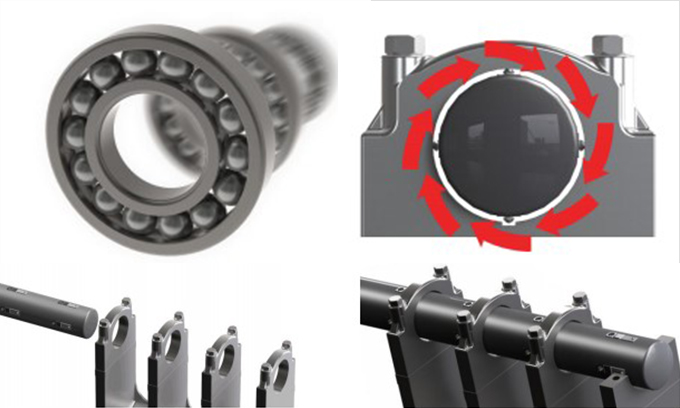

Bearing Checking using Mini Probes

APPLICATION: In automotive engine plants, camshaft bearings must be precisely manufactured and aligned, so that an engine runs smoothly and production stays constant.

SOLUTION: The Solartron Mini Probe is frequently utilized in these types of bearing checks. It is small enough to be mounted to a bore gauge and it is built to withstand rotation and side-loads, so the bore gauge can be rotated within the bearings to ensure camshaft is at its proper roundness. Custom tips can also be created, for easier pass-through. Since the probes come pre-calibrated, they only need to be mounted and mastered before use, ensuring an easy setup on the factory floor. |

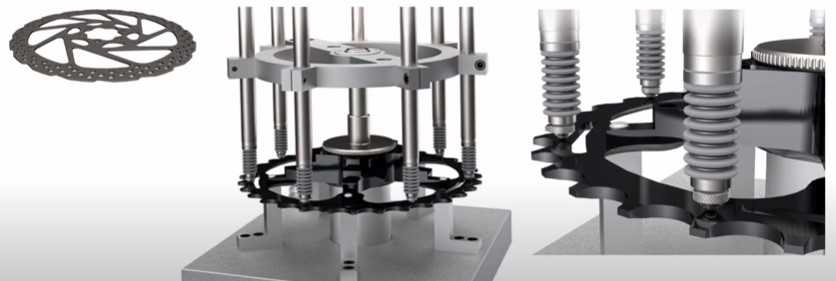

Measure Gears Dimension using Digital Probe

APPLICATION: Checking the height difference between gears, as well as to check the flatness of the gears.

SOLUTION: The probes used were DP series digital probes, where the accuracy is better than 1 micron, and resolution is 0.01 micron. All the reading of the probes can be synchronized and send to PC/PLC at the same time. |

Checking Dimension of Bicycle Components

APPLICATION: The 6mm thin body diameter of the probes are capable to check the end of bicycle forks. Thin bodies of the probes mean they can be held close together.

SOLUTION: Mini probes are used to check the width in between. The accuracy of the probes are better than 1 micron and the resolution will be as good as 0.01 micron. |

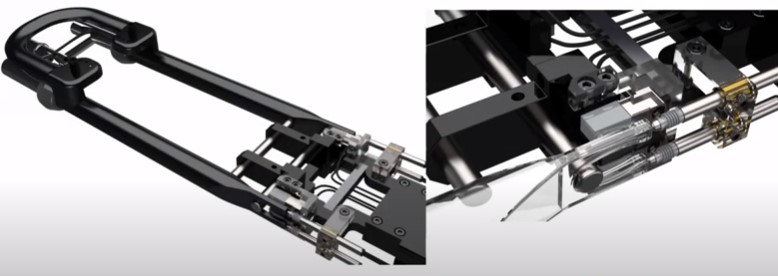

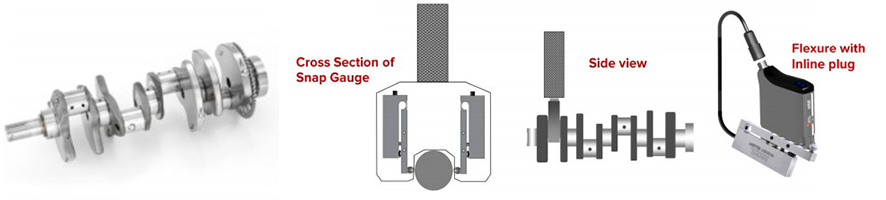

Checking Dimension of Crankshaft

APPLICATION: In automotive engine plants, crankshafts are built in high precision in an oily, humid and abrasive environment. All key dimensions, especially the diameters, must be checked quickly and measurement data logged for customer review. However, the gauges can be damaged and dropped by operators, so sensors that can be repaired and replaced must be available.

SOLUTION: With high endurance, easy setup and low maintenance, the Solartron Digital Single Leaf Flexure can be built into a Snap Gauge for Crankshafts. With an IP65 rating, it is built for harsh environments. It has been abrasively tested to 20 million cycles, and has a more robust design than similar flexures on the marketplace. If needs to stack multiple flexures together for taper measurements, they can easily be connected to Solartron Orbit 3 network, which runs up to 150 sensors. Orbit 3 ensures an easy, economical setup and simple outputs to a PC or PLC. |

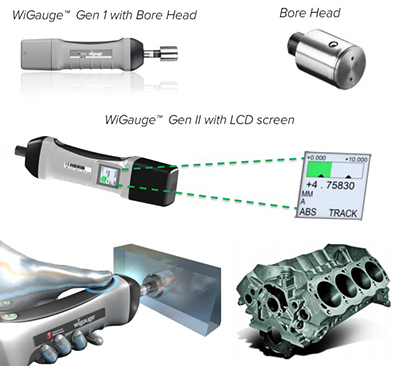

Using WiGauge to Record Readings

APPLICATION: In engine plants, machining centres are often used to mill out high precision bores into the engine block and head casting. Operators will typically make one pass, then stop the machine and check the diameters to ensure the bore is within the spec. This is either done with stand-alone dial gauges or wired bore gauges. Both pose problems, as the operator must separately record the data for a dial gauge, and a wired bore gauge means a long, cumbersome cable with no reading directly at the machine centre or elsewhere in the assembly process. Also, if multiple gauges are used, the cables can become tangled. Recording of data is key, as more end customers require data tracking of all key dimensions.

SOLUTION: The Solarton WiGauge solves the problems encumbered by other bore solutions in an easy, cost effective product. With the WiGauge, an operator can attach any bore plug, master it and then enter the machine centre to take readings. When a reading is taken, the lower button will flash red or green, giving a simple go/no reading, while the result is sent via Bluetooth to a computer. If the operator wishes to see a localized reading, an LCD screen on the side of the handle is available on the Gen II model, which not only gives a real time result but also any Peak+, Peak- or other programmed output. The customer will see cost savings from reduced measurement time and no need to manually record results. |