220

Quick ViewDatasheetView Full Details |

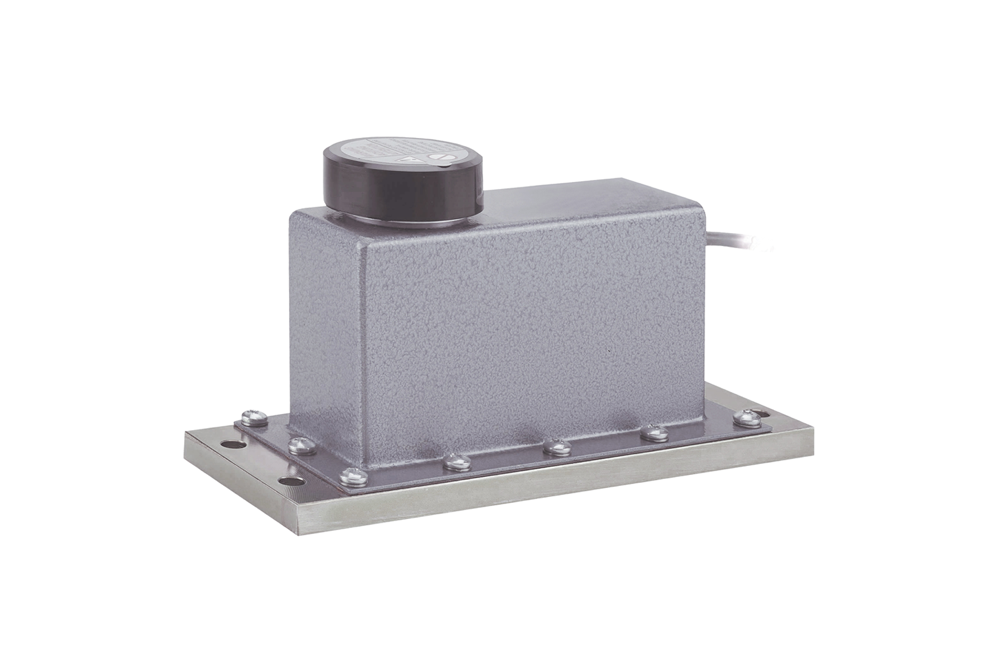

220The compression load cell 220 has been designed to operate in difficult and dangerous environments and it is suitable for weighing hoppers, tanks, silos and trucks. The load cell 220 is made of stainless steel and has a maximum capacity of 50 tons. The compression load cell 220 is used in industrial weighing and one of its strength is the easy installation. |

||||||

240

Quick ViewDatasheetView Full Details |

240The Model 240 is speciically designed to be used where the fast acquisition of a stable load signal is paramount. The Model 240’s unique fluid damping system allows the load cell to be used in applications that previously required the use of LVDT’s or similar measuring devices. The Model 240 brings load cell adaptability into check weighing and grading applications. Approved to OIML R60 and NTEP standards, sealed to IP66 level and available in coated steel or stainless steel, the Model 240 is suitable for most wash-down applications. The two additional sense wires feed back the voltage reaching the load cell. Complete compensation of changes in lead resistance due to temperature change and/or cable extension, is achieved by feeding this voltage into the appropriate electronics. |

||||||

355

Quick ViewDatasheetView Full Details |

355The Model 355 is a welded bending load cell manufactured in stainless steel. Hermetically sealed against moisture, the Model 355’s construction and polyurethane shielded cable enables the load cell to function in harsh environments while maintaining its operating speciications. The low proile, high accuracy and sealing makes this load cell highly suitable for applications such as low proile platforms, weighing and packing machines, conversion of mechanical and a variety of other applications where sealed cells are required. For hazardous environments this load cell is available with EEx ia IIC T6 level of approval as an option. The two additional sense wires feed back the voltage reaching the load cell. Complete compensation of change in the lead resistance, due to temperature change and/or cable extension, is achieved by feeding this voltage into the appropriate electronics. |

||||||

380

Quick ViewDatasheetView Full Details |

380Model 380 is a very low profile planar beam design, allowing direct mounting in low profile platform scales. The range of capacities and low profile make Model 380 most suitable for use in a wide range of applications. |

||||||

620

Quick ViewDatasheetView Full Details |

620The Model 620 is a stainless steel S-type load cell. Its welded sealing combined with high accuracy, make this load cell ideally suited for a wide range of applications of process weighing and force measurements. Approvals include OIML C3 (3000d); NTEP 3000d single and NTEP 5000d multiple. Also available are versions approved for hazardous areas—ATEX II 1 GD Ex ia T6 for Europe and FM I, II, III Division 1 for the USA. The six-wire cable includes two sense wires that compensate for changes in lead resistance due to temperature changes and cable extension. The Model 620 offers a choice of bolt threads in metric or uniied systems |

||||||

MKX MK0

Quick ViewManualVideoView Full Details |

|

||||||

MKC

View Full Details |

|

||||||

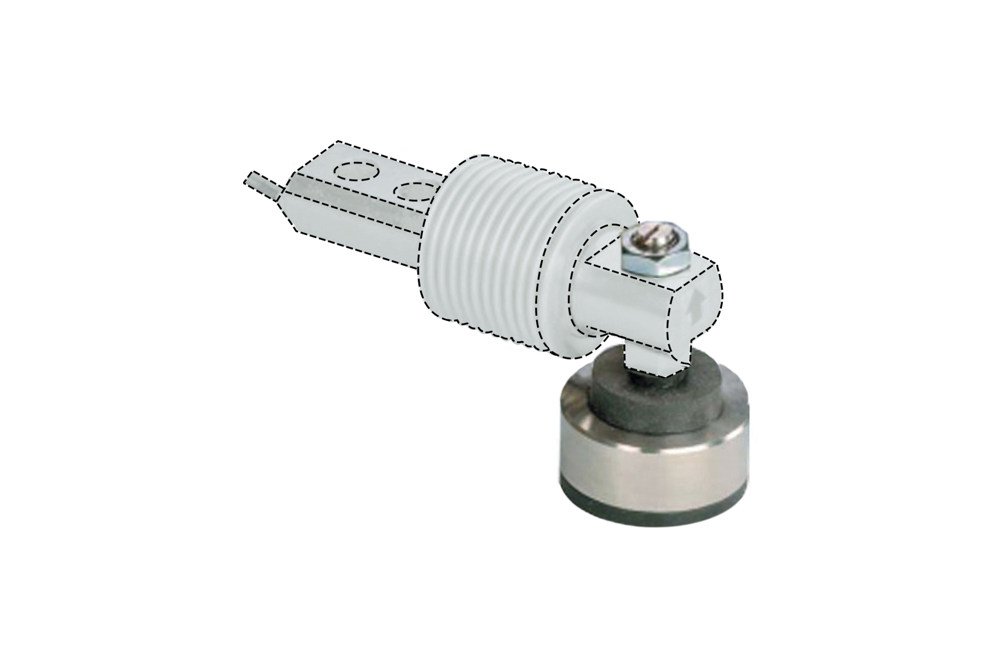

Load Foot

View Full Details |

|

||||||

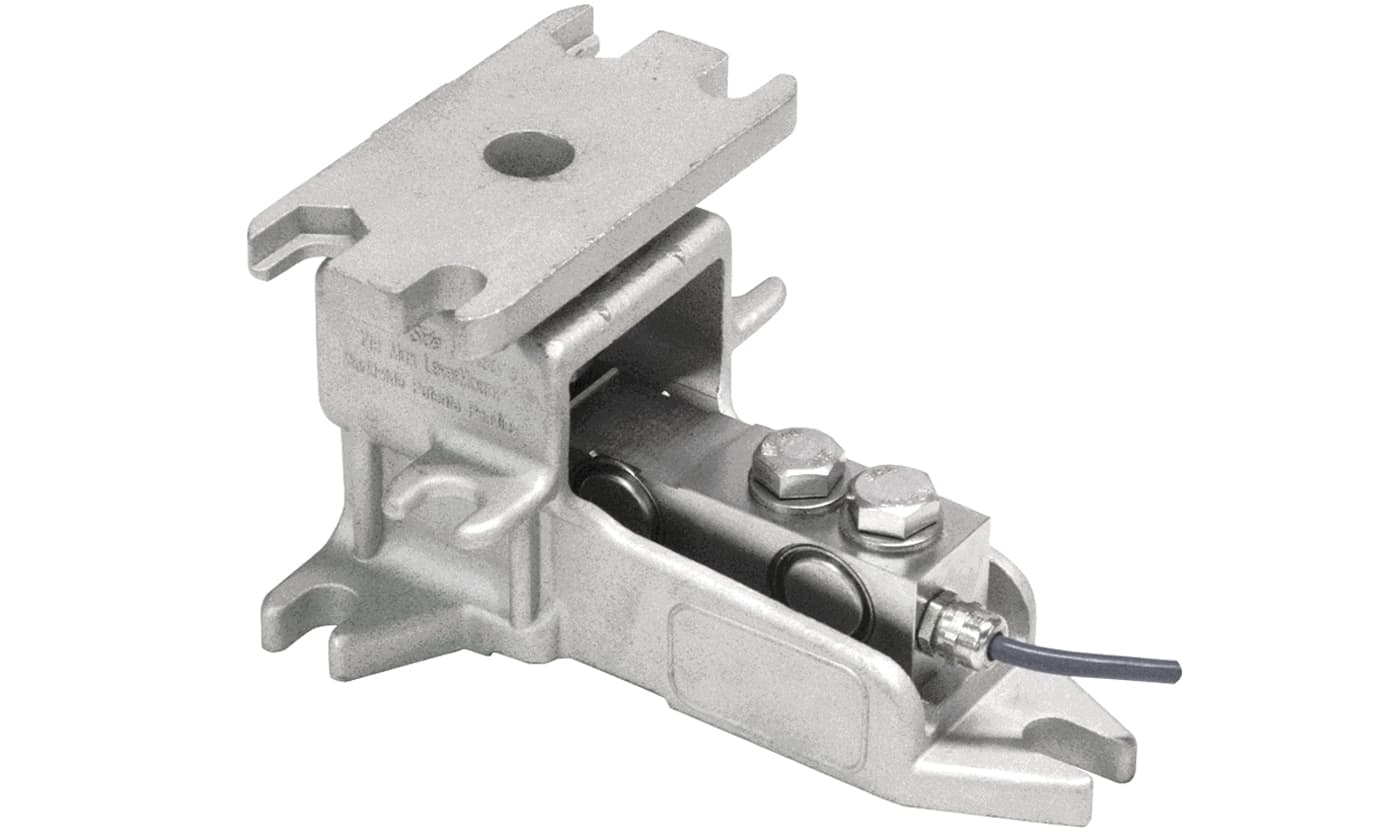

LEVERMOUNT Size 1

Quick ViewVideoView Full Details |

|

||||||

MASTERMOUNT

Quick ViewView Full Details |

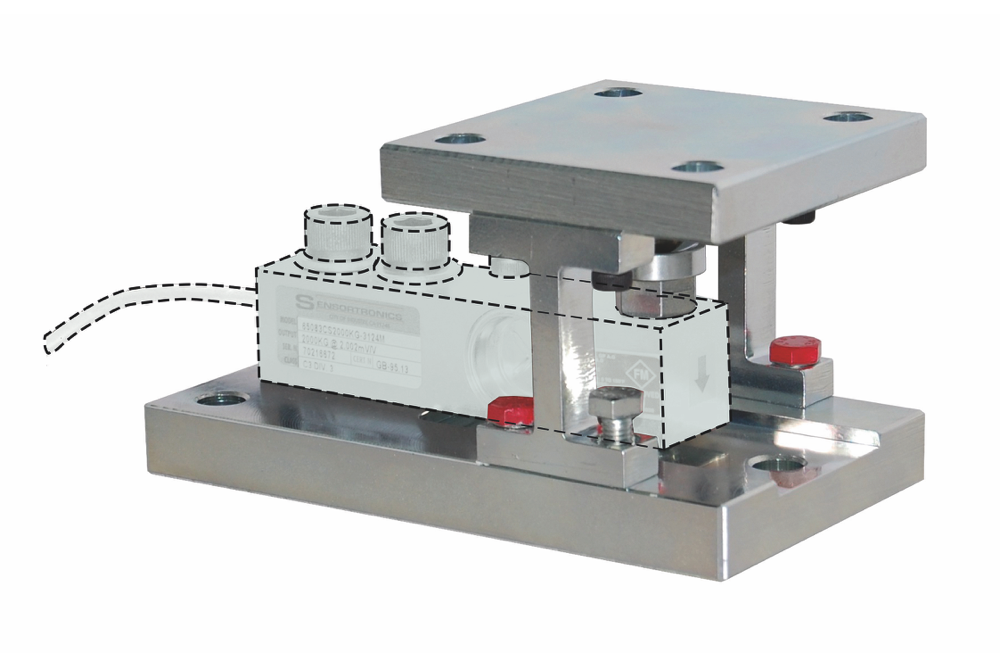

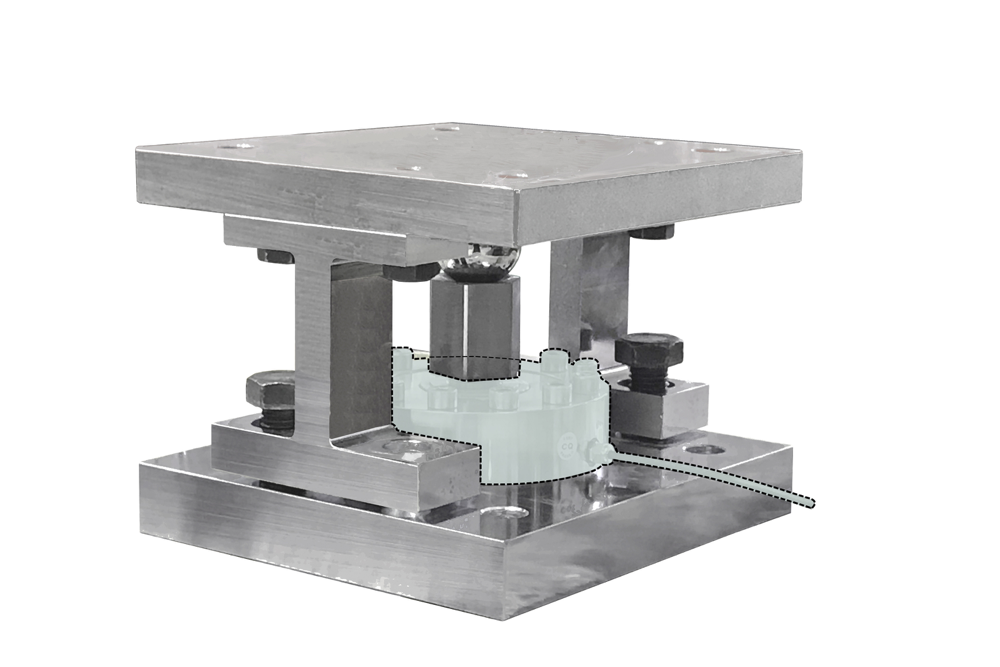

The MASTERMOUNT weighing module is an aesthetically appealing product; it has a double shear beam load cell made of stainless steel and a built-in mounting component. MASTERMOUNT is ideal for weighing processes that require accurate, safe and convenient solutions and can also be used in the most hostile industrial environments as it covers most industrial process applications. MASTERMOUNT is supplied with 20 m long shielded polyurethane cables for the electrical connection. The load cell and the assembly component of the MASTERMOUNT product cannot be sold separately, the weighing module must be purchased in full (see image). |