CSP2008

Quick ViewView Full Details |

One

method of measuring thickness is to calculate values from two opposing distance

sensors. With up to six inputs, the CSP2008 universal controller allows

synchronous recording of measured values from optical sensors: A pair of

sensors is connected directly to the controller, another pair is connected via

the EtherCAT fieldbus coupler and an integrated extension terminal. Two analog

sensors measure the width of the material. These sensors are connected via a

dual-channel analog input terminal. After the sensors have recorded their

values, the CSP2008 calculates material thickness and width. Three switching

inputs are used to set masters as per a calibration standard. |

LLT

Quick ViewView Full Details |

Heat

exchangers in plant and machinery serve as heat transfer mechanisms between

different material flows. To maximise the heat-emitting area, they are designed

using multiple plates. Respectively one connecting flange for the

material-conveying cables is welded or soldered onto the last plate. The

position and the flatness of the flanges have to fulfill highest requirements

so that these can be connected at the desired point. |

LLT

Quick ViewView Full Details |

Coordinate measurement machines are usually used for measuring many different components. Different scanners and measuring equipment measure the surface of the component in three dimensions by touching the surface of parts. Laser line scanners from the scanCONTROL 2800 and 2700 series are ideally suited for this purpose. They measure the actual surface of

the component without contact and with micrometer precision according to the

triangulation principle. |

LLT

Quick ViewView Full Details |

Mabotic develops and manufactures various designs of digital scanning units.

scanCONTROL laser scanner are often used for digitization of parts. The scanner

projects a laser line onto the object being measured and records the profile of

the line. When the scanner is mounted on a linear axis and the scanner

traverses over the measurement target, a 3D image of the target can be

generated. |

LLT

Quick ViewView Full Details |

With

sectional doors for parquet or laminate flooring, key and slot joints for

individual sections are applied. However, these sections are opened and closed

frequently. To enable a robust but permanent flexible key and slot joint,

specified dimensions are critical and must

be adhered to. This is particularly important in the case of significant

temperature differences or inaccurate dimensions, where the door could be

locked or positioned incorrectly. The measurement of the key and slot joint is

therefore critical in ensuring the correct manufacturing dimensions. |

LLT

Quick ViewView Full Details |

A

German manufacturer of prestressed concrete products uses a number of 3D

measurement systems by InSystems Automation with optical sensors made by

Micro-Epsilon for quality control of railway sleepers. The systems include a

portal station that is fitted to a forming station above the conveyor

technology. Two scanCONTROL LLT2800-100 laser profile sensors travel along the

portal axes and scan the sleepers from above. |

LLT

Quick ViewView Full Details |

Measuring

complex part geometries is a task for the scanCONTROL laser scanner. Laser

scanners are used in the precision machines of EHR in order to perform a

component inspection at high resolution and without contact. The special

feature is that using a scanner, not only is an inspection possible from the

outside but also from the inside. |

LLT

Quick ViewView Full Details |

The

company „Paul von der Bank“ in Hilden (Germany) develops and manufactures

modular-designed robotic welding cells and fully automatic production and

processing lines. To ensure high production quality of longitudinally welded

pipes, the following factors must be considered: Besides sheet edge length, the

exact edge position must be known, it must be guaranteed that sheet edges are

aligned perfectly to each other. |

LLT

Quick ViewView Full Details |

For

automatic welding processes, the quality of the weld is often dependent on how

precisely the welding head is positioned for the seam place. If the positioning

is checked by a measurement system before the welding, unnecessary rejection

can be prevented right from the start. The elster company uses the scanCONTROL

2810 profile sensor for this. The position of the scanner to the valve is

initially measured eight times before the welding process. The laser welding

head is positioned to the seam based on these data. |

DT 619.04

Quick ViewView Full Details |

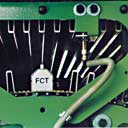

The

setting of the distance between the drum and the flat is crucial for carding

quality of fiber, e.g. wool. Investigations have shown that manual gap settings

with the gage to the left and right on the carding machine are not equal and

that with the machine at standstill slight deviations from the operating

conditions arise. The remedy is provided by a measuring flat rod (FCT) with two

or three capacitive sensors which is exchanged for a flat rod. The sensors

measure the distance to the drum via the drum width. The other distance signals

are passed to the PC. The fully automatic measurement sequence eliminates

erroneous settings and shortens the setup time. The inspection and

documentation of the results facilitates practical quality assurance. |