Expert Logger

Quick ViewView Full Details |

Portable Energy Monitoring tools Energy efficiency has become an important topic for industrial companies as part of Singapore’s energy transition and the requirements of Green Mark Certification. Energy savings can be determined using Delphin's energy-measurement case. The case is based on Message and Expert devices which can function and record measurement data independently without the need for PC support. The devices are highly flexible and the measurement case has been designed according to customer requirements. This enables the system to be used for a range of tasks on plant, machinery and components. Analog inputs record pressures, flows, quantities; impulse inputs record energy, gas and water consumption. Electrical measurement transducers enable 4-phase power data to be acquired. For evaluation, the easy-to-use ProfiSignal software provides all the necessary tools. Application features

Typical application features

|

Expert Logger

Quick ViewView Full Details |

Crane Condition monitoring (Black Box) Cranes are complex systems made up of many different component types. They need to be continuously available, have low operating costs and high productivity and therefore justify the use of a monitoring system that uses Expert Logger or ProfiMessage devices. These ensure continuous monitoring for wear and tear as well as detailed analysis in the event of a fault. Digital and analog signals can be acquired and recorded independently within the Message device. A partitionable data memory enables differentiated storage of fault data including pre and post histories as well as long-term data for condition monitoring. The crane data can be accessed via UMTS, WLAN or a USB stick and evaluated using ProfiSignal. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

Machine vibration measurement Unintended and high-level vibrations in machinery and test stand applications result in uneconomical operation and potential damage. Using Expert Vibro devices, different types of vibration sensor undergo unfiltered processing within frequency spectra ranging from 0 to 20.000 Hz. Excitation frequencies can then be determined to enable process optimisation. The Expert Vibro devices are capable of continuously acquiring and monitoring the levels of damaging frequencies and can operate fully independently due to their integrated internal data loggers. Visualisation takes place using the ProfiSignal software with data being portrayed in cascade, FFT or trend diagrams. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

Long Term Vibration analysis Vibrations are generally caused by faults and therefore need to be avoided. Machinery can suffer damage through vibrations with a negative influence on product quality. Vibrations can be perceived as noise, wobbling, shaking or whistling. The source of the vibrations requires identifying and rectifying. The Expert Vibro device is ideal for such tasks. Its universal inputs enable the connection of any type of sensor signal. Signal analysis takes place online using highresolution spectra or characteristic-value computations. Characteristic values possess all the relevant information about the energy content of vibrations. Whenever vibrations occur, the independently operating Expert Vibro records all relevant data. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

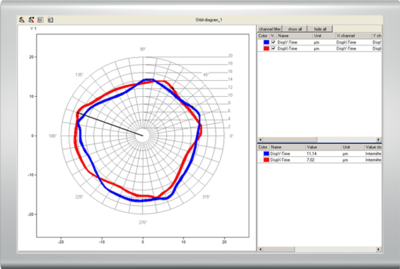

Shaft Vibration Measurement Up to 16 shaft vibrations can be synchronously acquired, analysed and monitored. Both static shaft positioning and dynamic shaft vibrations can be determined from the bearing casings. Radial shaft positioning and rotation speeds are also acquired via a KeyPhasor™ on the shaft. Phase information can be calculated from the shaft position. From the measured time signal, the Expert Vibro device can directly calculate spectra and characteristic values such as smax or peak-peak. The data can then be independently recorded or transmitted via Ethernet or PROFIBUS-DP to a central system or PC. Using ProfiSignal‘s Vibro software option, measurement data can be portrayed and evaluated in orbit, polar, bode or FFT diagrams. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

Bearing Condition Monitoring The diagnosis of bearing damage in roller bearings is an integral part of servicing and maintenance tasks. Condition monitoring systems (CMS) are increasingly being used for machine diagnoses. Many CMS systems are based on vibration measurements. Two contrasting approaches exist: diagnostic, qualitative approach (envelope spectrum); quantitative approach (vibration velocity). Delphin's Expert Vibro Devices are suitable for both approaches. The quantitative approach integrates the acceleration time signal into vibration velocity. The vibration velocity is then usually monitored as a sum level. An Expert Vibro device is able to calculate an envelope spectrum from the time signals of acceleration sensors. it provides detailed information on the condition of the bearing (inner and outer rings, cage and ballbearings). Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

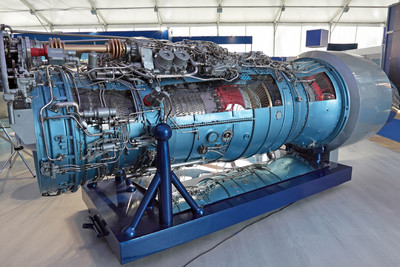

Turbines/generators monitor Vibrations on turbines and generators can be monitored for improper vibration values irrespective of power class and bearing type. The vibration velocity is typically monitored. By using Expert Vibro devices, vibration velocity sensors can be used. The vibration velocity from the sensor signal is measured proportionally and converted into an effective value. If vibration acceleration sensors are used, the signal is integrated online and transferred into vibration velocity. The TRMS and peak to peak es are then created and continuously monitored by threshold channels. If a threshold is exceeded, digital outputs are switched or messages sent to controllers via a fieldbus. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

Presure vibration monitoring In addition to conventional vibration measurements, monitoring can also be performed on dynamic pressure vibrations in the combustion chambers of gas turbines. Temperature resistant pressure sensors are installed within the chambers to measure dynamic pressure vibrations using Expert Vibro devices. Dynamic pressure vibrations contain information relevant to machine safety and analysis. Narrow-band characteristic values are determined and monitored from FFT analyses of the pressure signals. The Expert Vibro device directly determines and monitors TRMS values for each frequency band. In the event of an alarm, the central system is notified via PROFIBUS, or a digital output can be triggered. Spectra are portrayed in a spectrogram via ProfiSignal. Application features

Typical areas of application

|

ProfiMessage

Quick ViewView Full Details |

Vibration and process data Process measurement technology usually involves the acquisition of mA or mV sensor signals with limited temporal resolution. The demands are higher when acquiring transient events or vibrations. Data acquisition rates are much higher and a more sophisticated evaluation is required. Systems from different suppliers are therefore necessary with subsequent problems of compatibility. However, with the ProfiMessage series, Delphin offers systems ideal for measuring standard type signals. In combination with Expert Vibro devices, all data can be acquired, computed and monitored within a single system. The measurement data are all based on the same time scale and so are directly comparable with each other. Application features

Typical areas of application

|

Expert Vibro

Quick ViewView Full Details |

Vibration test stands Vibrations tests are carried out during the development of many products. Test samples are mounted on shakers and shaken and rattled according to requirements. Vibration measurements are taken at the shaker itself and at the test sample. Vibrations patterns at the test sample are referenced back to the shaker and frequencies, phase shifts and amplitudes undergo measurement. Expert Vibro is especially suited to such tasks. 8 or 16 synchronous inputs enable processing of all the required measurements. The device is also able to simultaneously control the shaker and provide set-point values. Digital outputs monitor characteristic values and can be used for switching procedures in the event of an alarm. Application features

Typical areas of application

|