|

|

|

Elevator Drive E300 AC Drives

3 - 400 hp (2.2 kW – 250 kW)

230 V | 460 V | 575 V | 690 V

Dedicated Drives For Class-Leading Ride Comfort

Control Techniques is a leading supplier of AC drive technology for the elevator industry, with over 3 million elevators in operation with our control equipment worldwide.

-

Rapid set-up and adjustment

-

Optimum ride comfort

-

Enhanced elevator data logger

Backed by our global network of Drive Centers we provide local expertise and support, along with quick delivery of robust and dependable products.

Our elevator drive solutions work for any size of building. Whether it’s a small residential building or a luxury high rise, new build or modernization projects, we make every step of the process as easy as possible from product selection to installation, setup and service.

Introducing the dedicated Elevator Drive

Adding value at every stage of your project

|

Freedom to design

-

Broad power range, compact form factor Broad power range, compact form factor

-

Match any control interface, any protocol Match any control interface, any protocol

-

Work with any motor, any feedback device Work with any motor, any feedback device

-

Multiple mounting options Multiple mounting options

-

Dynamic braking and regen solutions Dynamic braking and regen solutions

-

Back-up power and rescue modes Back-up power and rescue modes

|

|

Effortless installation and commissioning

-

Elevator specific menu structure Elevator specific menu structure

-

Stationary autotune Stationary autotune

-

Pluggable drive terminals Pluggable drive terminals

-

Robust cable management Robust cable management

-

Parameter storage, cloning and security Parameter storage, cloning and security

-

Keypad with backlit LCD display Keypad with backlit LCD display

-

Virtual terminal for access through the lift controller Virtual terminal for access through the lift controller

-

PC tools for set-up and tuning PC tools for set-up and tuning

|

|

Class-leading performance

-

Creep-to-floor and Direct-to-floor operation Creep-to-floor and Direct-to-floor operation

-

Selectable start, run, stop gains Selectable start, run, stop gains

-

Load cell compensation and start locking Load cell compensation and start locking

-

Start optimiser to overcome stiction Start optimiser to overcome stiction

-

Fast start mode Fast start mode

-

Floor sensor correction Floor sensor correction

-

Short floor landing operation Short floor landing operation

|

|

Maintenance and diagnostics support

-

Selectable status display parameters Selectable status display parameters

-

Diagnostics with timestamping Diagnostics with timestamping

-

Built-in data logger Built-in data logger

-

Normal Terminal Stopping Device support Normal Terminal Stopping Device support

-

Low voltage rescue mode Low voltage rescue mode

-

Blocked elevator car release Blocked elevator car release

-

Travel counter to help keep track the lifetime of plastic ropes Travel counter to help keep track the lifetime of plastic ropes

|

|

|

|

|

|

|

|

Keypads

|

|

Remote mountable keypad, allowing flexible mounting on the outside of a panel (meets IP54/NEMA 12). The keypad offers a four line plain text, multi-language LCD display for rapid set-up and helpful diagnostics. A battery operated real-time clock allows accurate time stamping of events, aiding diagnostics.

|

System Integration Modules - Communications

|

|

SI-DCP

DCP interface module

|

|

CANopen interface module supporting various profiles, including several drive profiles

|

System Integration Modules - Feedback

|

Encoder input and output interface supporting Quadrature, SinCos, EnDat and SSI encoders.

|

|

Quadrature encoder input interface module

|

System Integration Modules - Applications

|

|

Second processor module, which allows SyPTPro application programs to be re-compiled for Unidrive M700.

|

|

|

Second processor, providing advanced machine control using Machine Control Studio.

|

|

|

Adds to the MCi200 with a dual port Ethernet interface directly on the processor and additional I/O

|

System Integration Modules - Additional I/O

|

|

Extended I/O interface module to increase the number of I/O points on a drive. Provides additional: 4 x Digital I/O, 3 x Analog inputs (default)/Digital inputs, 1 x Analog output (default)/Digital input, 2 x Relays

|

Drive interface units - Backup

|

|

Smartcard memory device to backup and copy parameter sets and basic PLC programs.

|

|

|

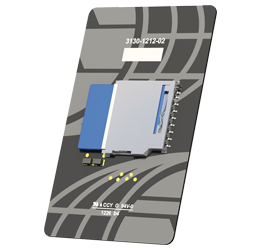

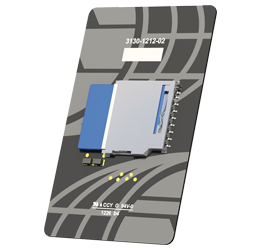

Allows an SD card to be inserted into the Smartcard slot, for parameter backup cloning and application programs.

|

Drive interface units - Communications

|

|

This allows the drive to communicate via RS485. This is commonly used for programming if the drive has no keypad

|

|

The USB Comms cable allows the drive to connect to a PC for use with Unidrive M's PC tools.

|

|

|

|

|

|

|

Broad power range, compact form factor

Broad power range, compact form factor