|

|

|

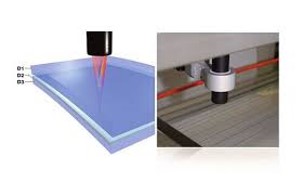

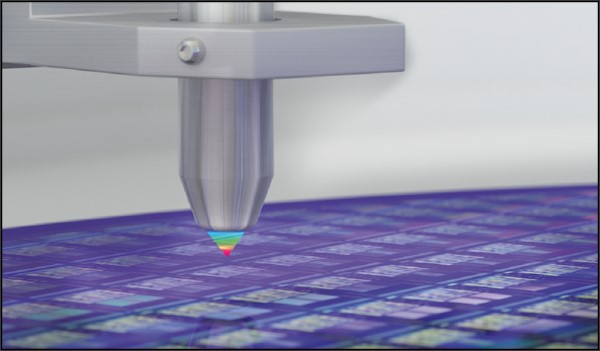

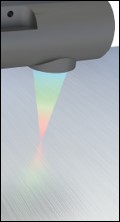

What is the measuring principle of confocalDT?

|

|

The confocal chromatic measuring principle Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic wavelengths by controlled chromatic aberration. To each wavelength, a specific distance is assigned by factory calibration. Only the wavelength which is exactly focused on the target is used for the measurement. An optical arrangement images the light reflected onto a light sensitive sensor element, on which the corresponding spectral color is detected and evaluated. In the case of multi-peak measurements, several distance points are evaluated accordingly.

|

|

|

|

|

|

|

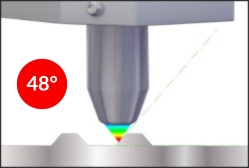

Extremely large tilt angle

|

|

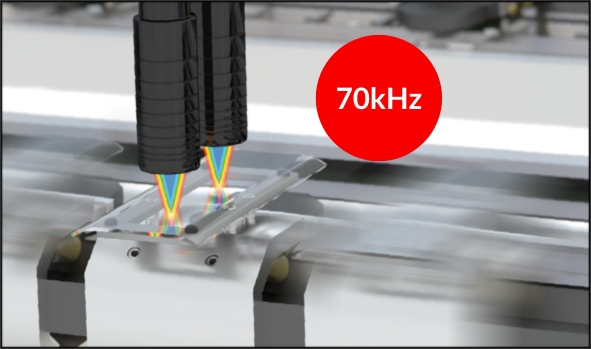

Dynamic measurement tasks

|

|

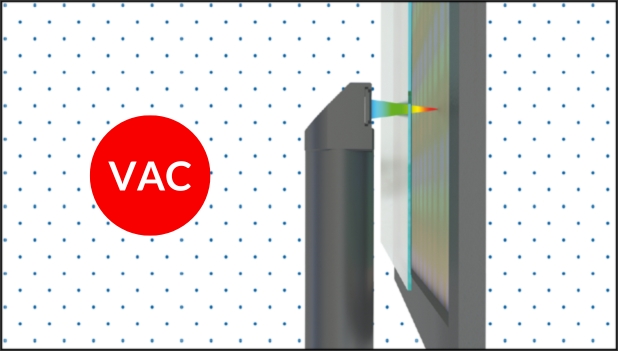

Ready for vacuum

|

|

|

|

|

|

|

|

|

|

|

|

Tilt angle up to 48°

|

|

Highest measuring rate in the world

|

|

Sensor designed from passive components

|

Stable signals with curved & structured surfaces Stable signals with curved & structured surfaces |

|

Dynamic exposure control for highest measurement accuracy Dynamic exposure control for highest measurement accuracy |

|

Vacuum-suitable sensors, cables and accessories Vacuum-suitable sensors, cables and accessories |

|

|

|

|

|

|

|

Smallest light spot

|

|

Ultra-small sensors

|

|

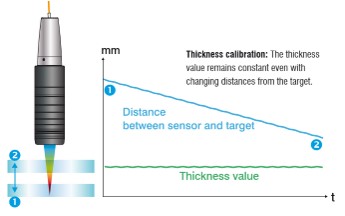

Thickness calibration

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Highlateral resolution

Detection of smallest details (e.g. IC pins on PCBs)

|

|

Sensors with a diameter from 4 mm for restricted installation space

90° models reduce the installation depth again

|

|

Highest measurement accuracy

due to stored target materials (refraction index)

|

|

|

|

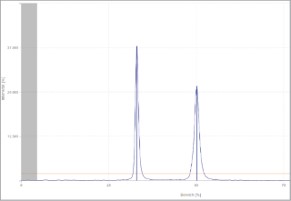

Multi-layer thickness measurement

|

|

|

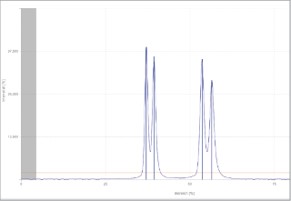

Signal with thickness measurement

|

|

Signal with multi-layer thickness measurements (max. 6 peaks)

|

|

|

|

-

Thickness measurement of transparent materials in the micron range Thickness measurement of transparent materials in the micron range

-

Measuring up to 5 layers with just one sensor Measuring up to 5 layers with just one sensor

|

|

|

Easy configuration via web interface

|

|

|

|

|

|

|

|

|

|

Controller type |

Channels |

Measuring rate |

|

confocalDT IFC242x |

Confocal controller for industrial applications |

1 or 2 |

Up to 6.5kHz |

|

confocalDT IFC246x |

Light intensive controller for high speed measurements |

1 or 2 |

Up to 30kHz |

|

confocalDT IFC2471 HS |

Confocal high speed controller |

1 |

Up to 70kHz |

|

|

|

|

|