|

||||||||||||||

3D Profile Unit – Smart 3D evaluation and results output of stitched 2D/3D profile data |

||||||||||||||

|

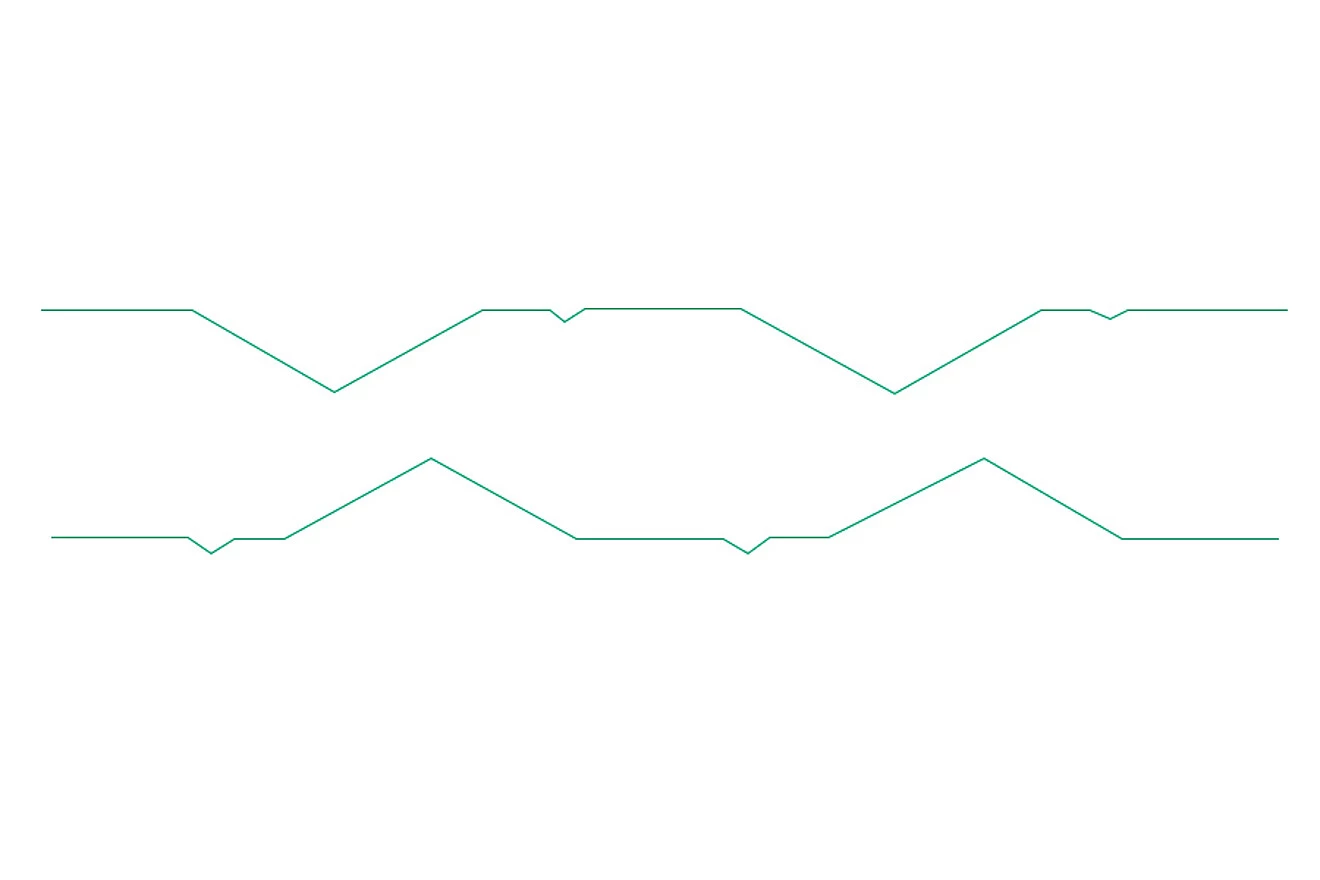

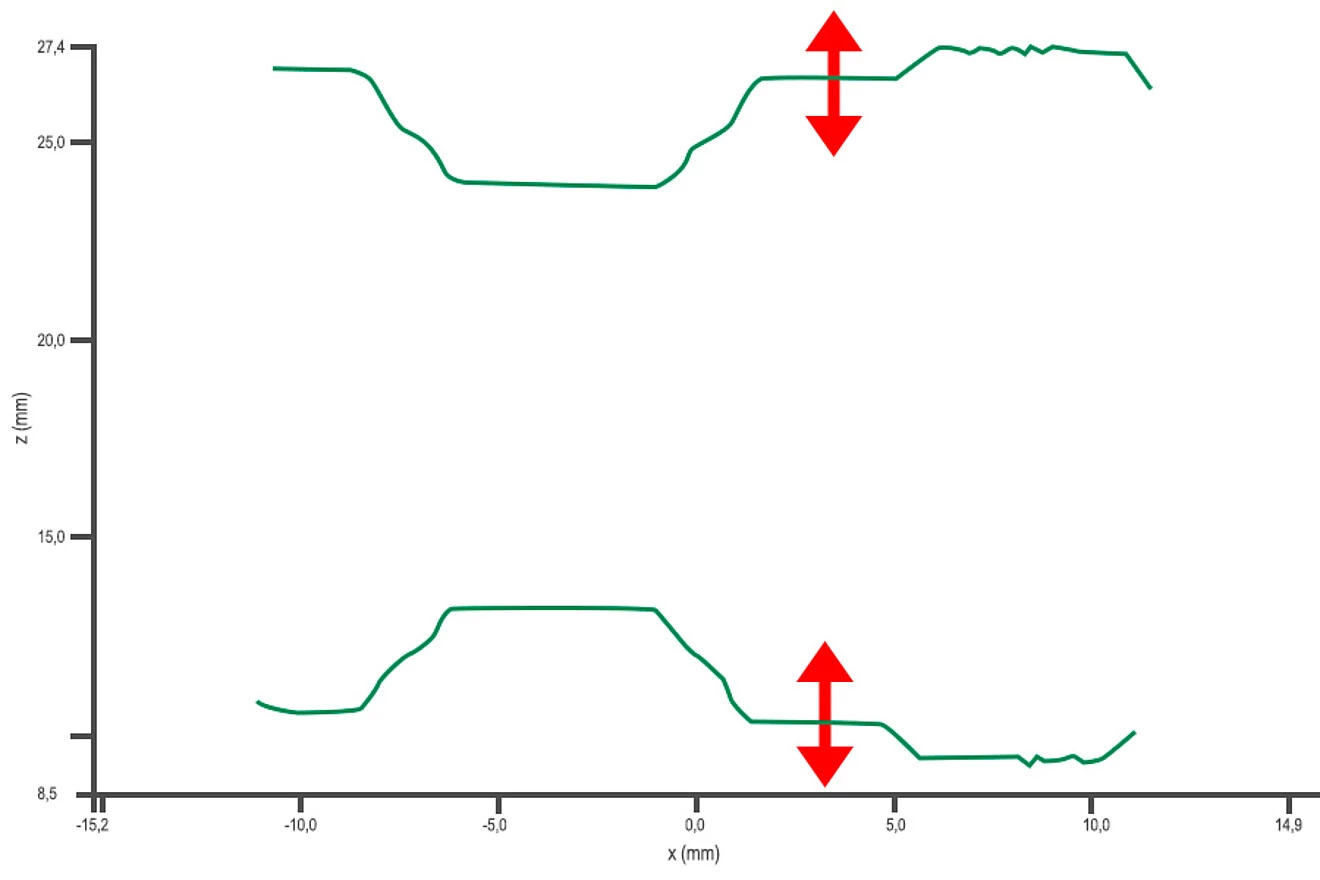

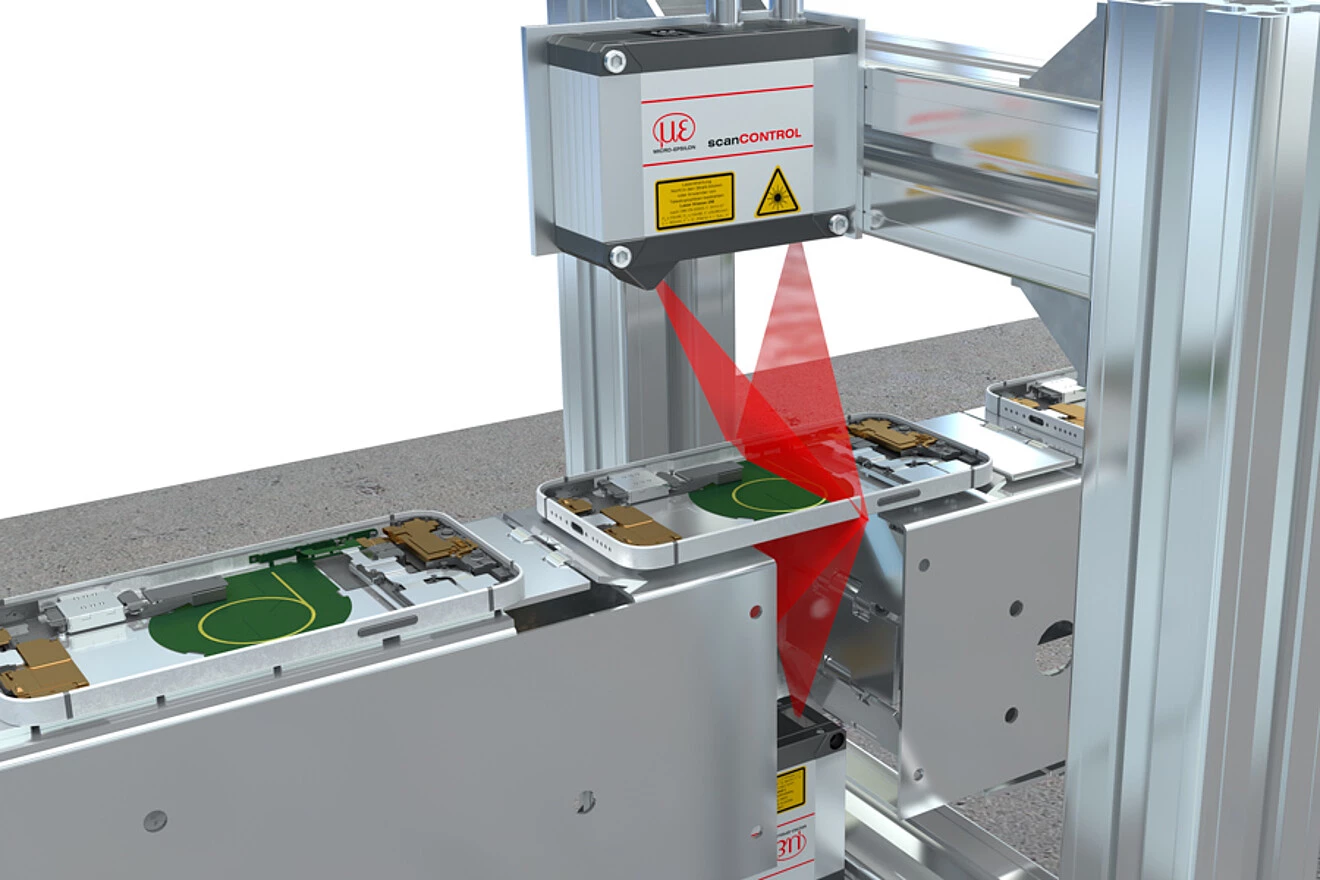

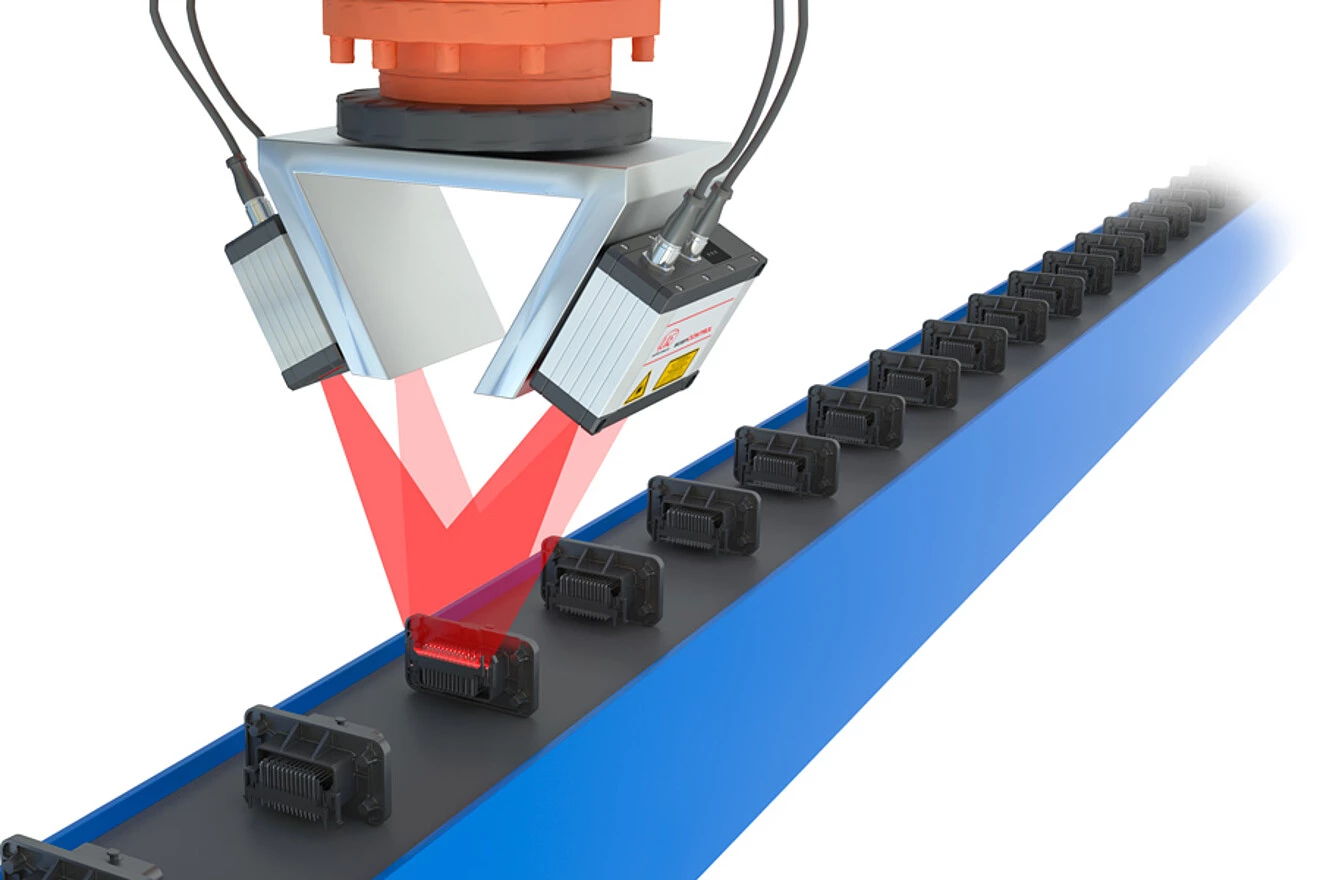

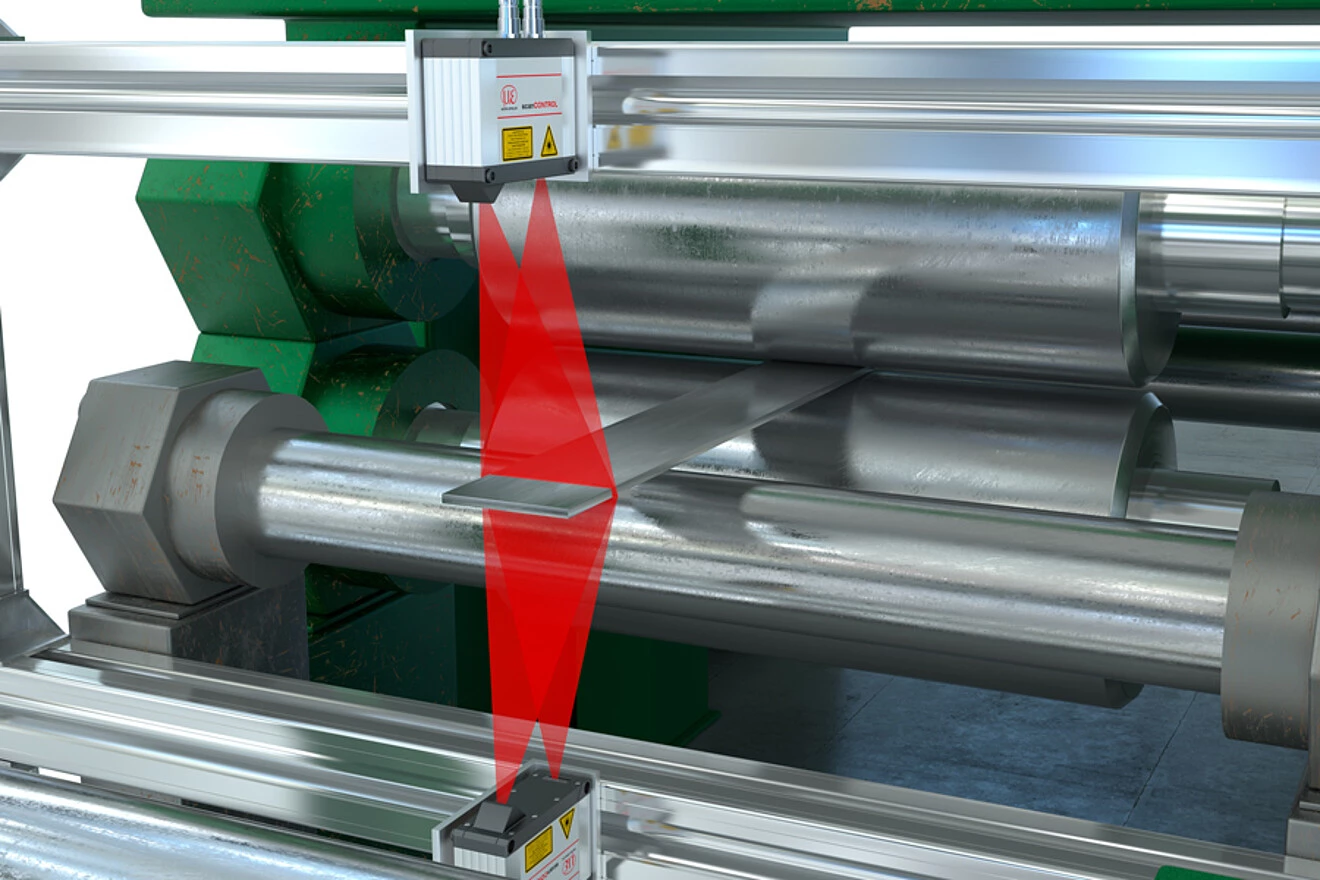

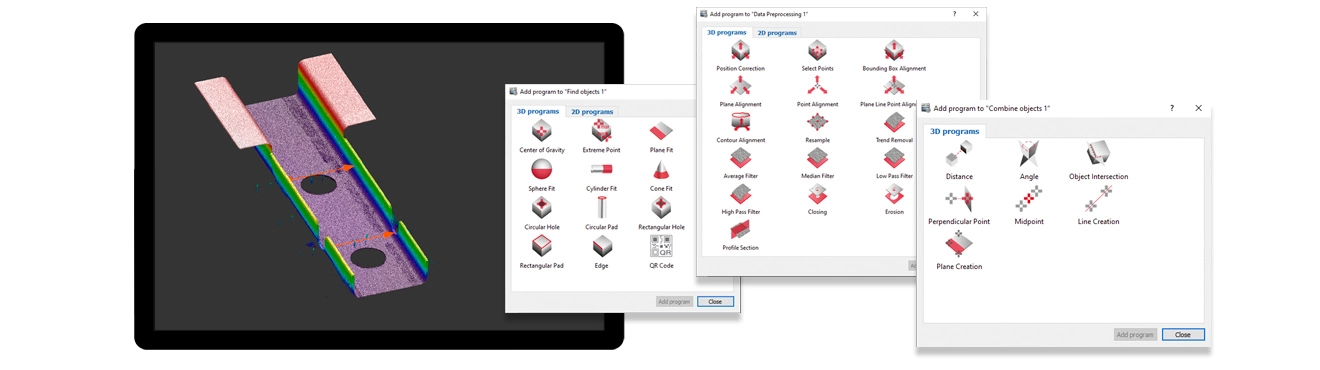

The 3D Profile Unit enables the calculation of several individual profiles of scanCONTROL 30xx sensors in a common coordinate system. This is how a composite 2D profile or a composite 3D point cloud can be generated. So the detection of various geometries, the extension of measuring ranges and the performance of thickness measurements is possible. The exact assignment of the position of the sensor to the position of the measurement object can be carried out via the integrated encoder inputs. The evaluation of the data and the parameterization of the system can be implemented in the 3DInspect software. The 3D Profile Unit controller has an integrated evaluation feature in conjunction with the Industrial Ethernet connection, enabling the application to be controlled and measured values to be output to a PLC. Alternatively, the 3D Profile Unit controller can also be integrated into common image processing programs via GigE Vision and acts as a raw data provider. |

||||||||||||||

|

||||||||||||||

3DInspect: Powerful software for all Micro-Epsilon 3D sensors |

||||||||||||||

|

||||||||||||||

| 3DInspect is a standardized and user-friendly software tool for the 3D Profile Unit. This software can directly parameterize the 3D Profile Unit and record the measured data. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller. | ||||||||||||||

Generation and transfer of stitched 2D/3D profile data: 3DPU-X |

||||||||||||||

|

||||||||||||||

|

3DPU-X is a system that converts the profile data of several scanCONTROL sensors into a common coordinate system and makes it available as 2D profiles / 3D point clouds via GigE Vision. Direct integration into image processing and 3D software | Communication with any GigE Vision clients | Transfer of profile data or 3D point clouds |

||||||||||||||

Smart 3D evaluation and result output of stitched 2D/3D profile data: 3DPU-X/IE |

||||||||||||||

|

||||||||||||||

|

3DPU-X/IE is a system that converts the profile data of several scanCONTROL sensors into a common coordinate system, evaluates the 2D profiles / 3D point clouds and makes the measured values available via integrated fieldbus interfaces, e.g. as good or bad results. Integrated evaluation and configuration via 3DInspect | Industrial Ethernet interface for control and transfer of measured values | Transfer of measured values and measurement results |

||||||||||||||

Micro-Epsilon registration targets for automatic registration |

||||||||||||||

|

||||||||||||||

|

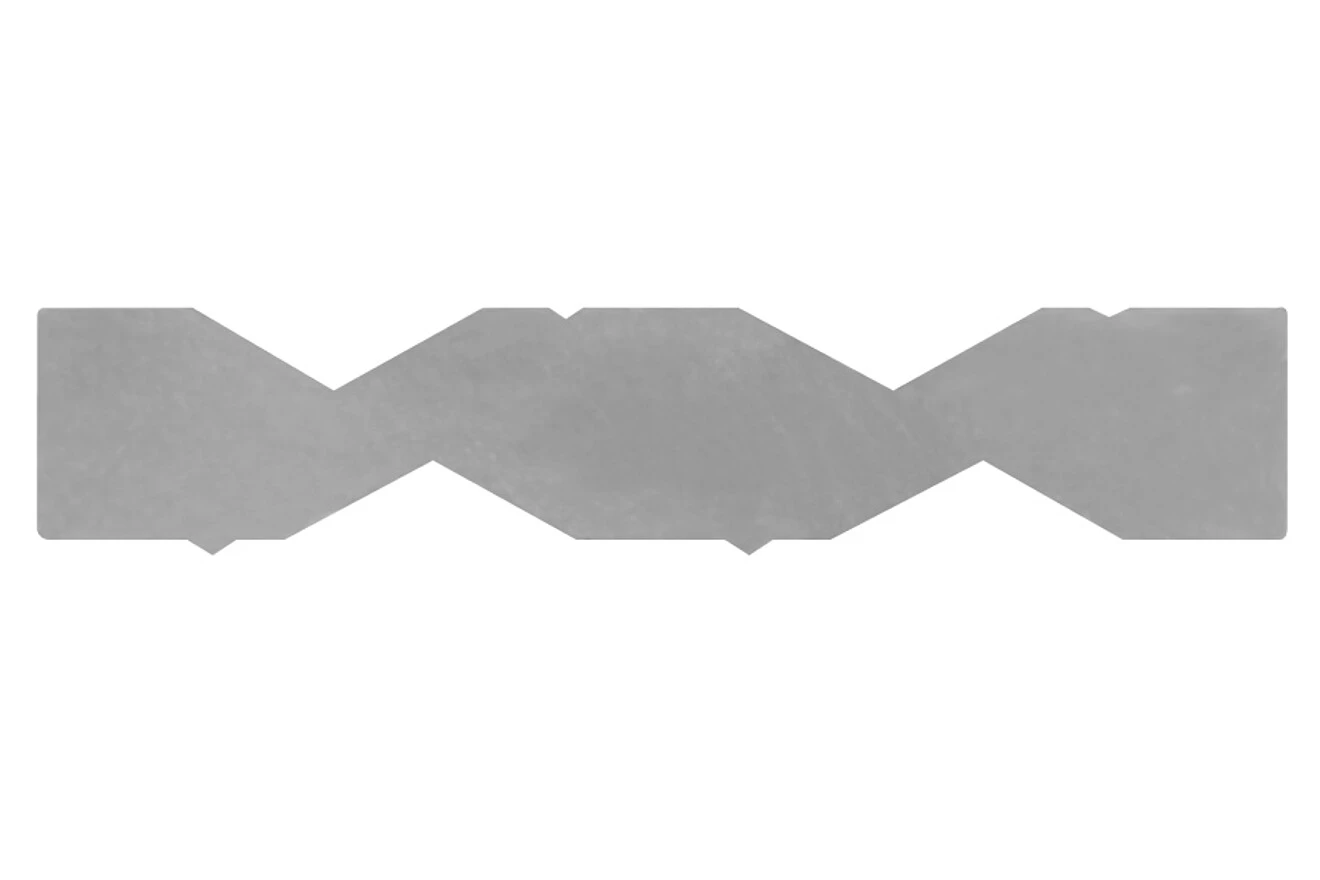

With multi-sensor registration, the position of each individual scanCONTROL sensor is determined and transferred to a common overall coordinate system. Registration brings the individual sensor readings into a common coordinate system during the set-up process. Micro-Epsilon offers an individual registration target for each measuring range of the scanCONTROL sensors and for each measuring arrangement. A special registration target can be designed for individual configurations and measurement setups. The sensors can also be registered without a registration target using a golden sample. |

||||||||||||||

Applications |

||||||||||||||

|

||||||||||||||

Profile stitching of up to 2 laser scanners

Profile stitching of up to 2 laser scanners