|

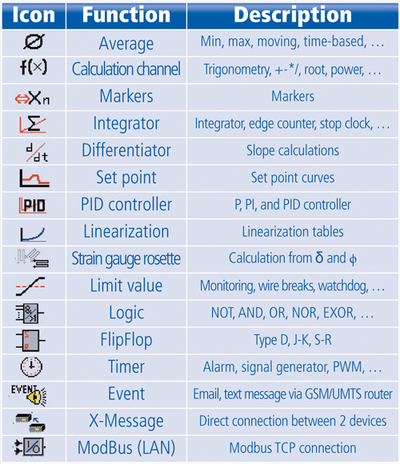

Software (virtual) channels can be used to extend the basic functions available within TopMessage devices. Software channels significantly

enhance the functionality of TopMessage devices by enabling additional functions to be performed directly within the device itself.

Software channels are configured according to individual user requirements and are part of the TopMessage's standard delivery. Simple

configuration procedures make costly programming unnecessary.

Monitoring and alarm functions

Threshold values can be set for any physical or virtual channel (analog, digital, calculation channel etc.). Distinctions are made between overruns, underruns and process violations. The information from a threshold violation can be viewed in ProfiSignal, e.g. via warning lamps. Digital outputs can also be performed, e.g to sound an alarm siren or to open or close a valve. A threshold violation can also trigger the sending of a text message, email or fax. This takes place directly within the hardware either without PC support or by using ProfiSignal's alarm management option.

Calculation channels and logic functions

Logic functions gather together threshold values as batch alarms and generate timers, flipflops and triggers. Typical functions such as OR, NOR, XOR, AND etc. are available within logic channels. These software channels can also be used as triggers for memory groups, e.g. to store pre and post data during fault events, and at no additional cost.

Calculation channels have basic and scientific calculation functions that enable simple online calculations using formulae (averaging temperatures, pressures, root, exponential functions, moving averages and logic functions). Similar to physical channels, calculation channels can also act as data sources for threshold values or alarm signals, and can be portrayed in ProfiSignal diagrams.

Integrators and differentiators

Data acquisition systems often require the calculation of flow rates, energy consumption, etc. according to time or impulse/time periods. Integrators and differentiators are available for time-dependent functions as well as for edge counters and operating-hour counters

.

PID controller

Controllers establish controlling links between measurement channels. They operate as continuous PID controllers on analog outputs. Typical applications include the controlling of temperatures, fill-levels and pressure-levels. The AAST module, with 4 analog inputs / outputs, is ideal for control procedures.

A multitude of applications and integrated preprocessing systems requiring no additional PC-support

These and other existing virtual channels can be linked to physical and non-physical channel types. This enables the direct set up of a multitude of applications, especially in process automation, without the need for additional hardware.

Funtions | Models | I/O Modules | Interfaces | Software Channels | PC Software | Technical Specifications |

![]()

|

|

|

|

|

|