|

DOWNLOADS |

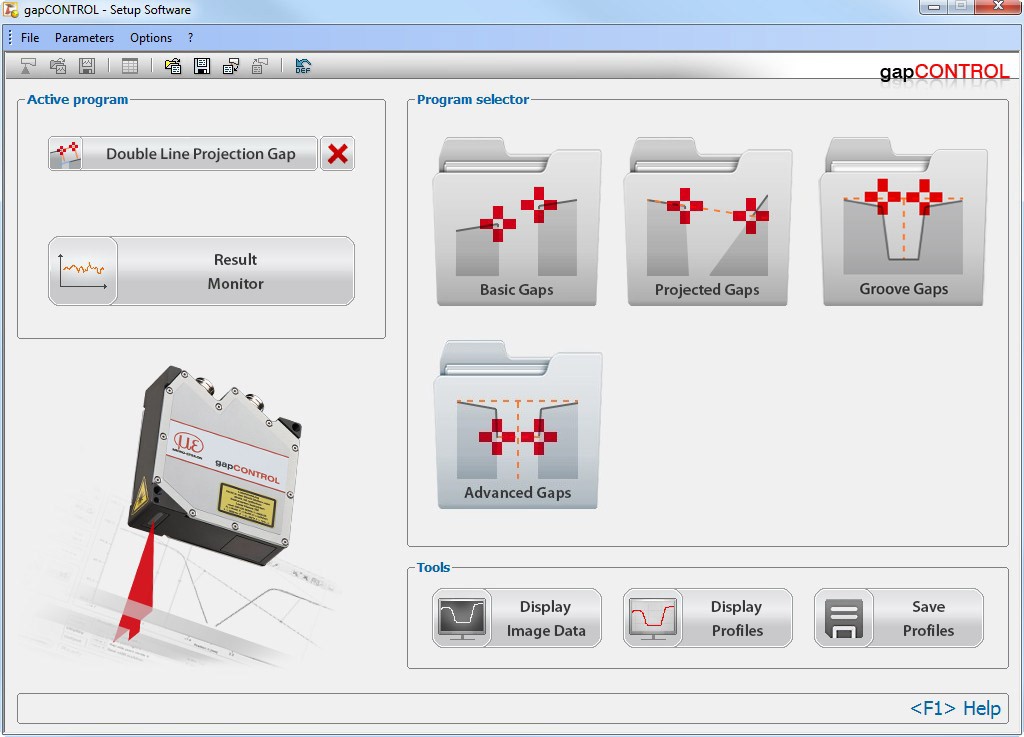

gapCONTROL Setup SoftwareGap measurement and evaluation means to be a complex task. In detail, there are different definitions of how the optical gap is defined for different industries and measuring targets. The gapCONTROL Setup Software has been precisely adjusted to the requirements of the different gap measurements and it makes configuration of gapCONTROL sensors quick and easy. The gapCONTROL Setup Software, together with the gapCONTROL sensors, represents a complete solution for automated gap measurement. After parameterization, the sensor operates in standalone mode. However, the software can be used for the visualization of the measured values. Setup gapCONTROL sensors

The gapCONTROL sensors offer different options and settings. All these settings can be accessed with theConfiguration Tools software. One possibility is accessing directly the image of the sensor matrix to set up the sensor optimum to the target. This view displays a live image of the matrix and helps to eliminate reflections on the target surface.

Display, save, load and exports profiles

ThegapCONTROL Setup Software allows both profiles and measuring results (e.g. gap width) to be saved. Stored profiles, even without a gapCONTROL sensor connected, can be re-loaded, and all parameters of the evaluation can be tested on this offline data. Several example profiles are already included with the standard installation of the gapCONTROL Setup Software, and they can largely be used to test the how the software works.

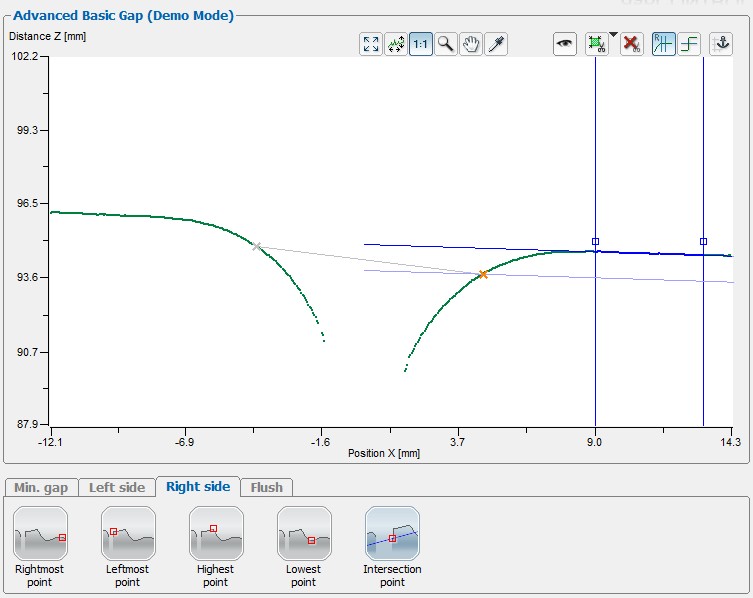

Gap modesThe user-friendly, intuitive software guides the user through the program. In the first step, a gap mode is chosen from a wide selection of gap types. "Basic Gaps", "Projected Gaps" and „Groove Gaps“ require little or no settings."Advanced Gaps" provides the user with configurable advanced parameters, executing complex gap measurement tasks.

Setup and configuration of gap measurementsThe next step is to specify the search algorithms for the right and left-hand edges. The simple "Basic Gaps", "Groove Gaps" and "Projected Gaps" already contain the correct algorithms. In addition, the software allows the user to determine the algorithms for measuring the offset (flush) and the projection between both sides.Global sensor settings can also be made quickly. For dynamic processes, gapCONTROL also offers a tracking functionality, e.g. following the center position. Measurement output

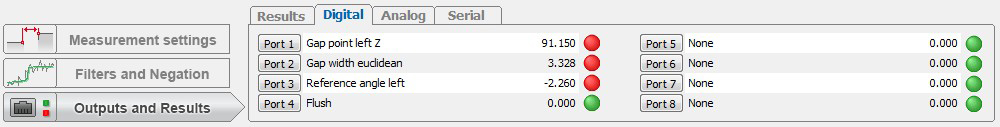

For output of measured values, these can be configured with freely assigned values. As well as measurement value output via Ethernet (Modbus TCP protocol, UDP) and RS422 (Modbus RTU protocol or ASCII format), additional digital switch signals and analog measuring values can be output by using an output unit. The last step comprises the transmission of the entire parameter set to the gapCONTROL scanner, which allows up to 15 parameter sets to be stored and to activate these by applying a control command. The profile analysis now operates entirely autonomously and directly in the scanner without connection to a PC. Analysis program for measurement value sequence

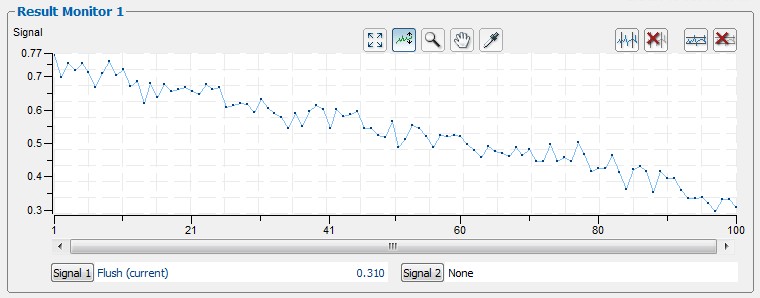

Using the "Result Monitor" analysis program, selected measurement value sequences of recorded profiles and live profiles can be displayed and analyzed, enabling the evaluation of measurements. Additionally, an integrated cgm analysis (capability gage measurement), and further statistical parameters (e.g. limit value exceeded, average values) are available. The software allows these values to be exported for archive purposes or for further analysis in calculation tables. |