|

|

Cold mills |

|

|

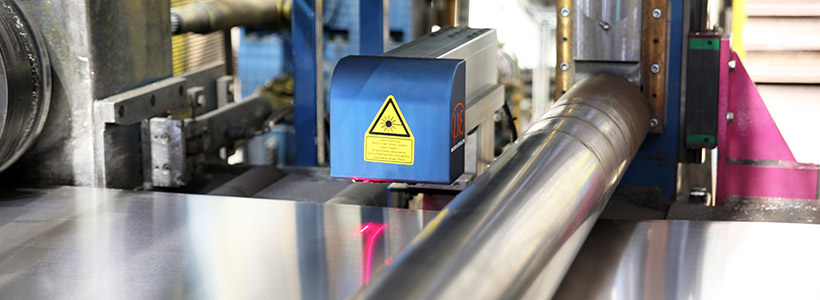

Thickness measurement for control and quality inspection is at many positions and so is an important element in the process landscape of cold rolling mills. Common places of application for systems detecting the center thickness or the cross profile are tandem lines and film stands. Based on confocal sensor technology or laser line triangulation, Micro-Epsilon offers high-precision thickness measuring systems with the thicknessCONTROL MTS 8201/8202 series, which operate with high precision in the submicrometer range. |

|

|

|

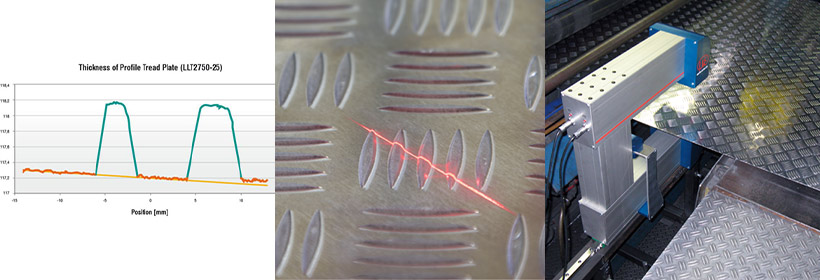

Measurement of inner and total thickness of checker plate with thicknessCONTROL MTS 8202.LLT C-frame systems |

|

|

|

|

One application that can only be solved with laser line technology is the measurement of the inner and total thickness of checker plate. Since the laser line covers a significant portion of the pattern, its maximum and minimum can be reliably detected. In addition, the variants of the thicknessCONTROL MTS 8201/8202 series, in which laser line technology is used, demonstrate their advantages especially under the harshest environmental conditions:

|

|

Flexible portfolio with O- and C-frames

Flexible portfolio with O- and C-frames