Measurement of the zinc strip color in the production plant

In the production of high-quality material strips and boards made out of titanium zinc, the surfaces receive specific treatment. Therefore, the coloring of the zinc products is already determined during the production process. |

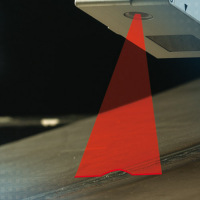

Weld seam inspection on pipes

A perfect weld seam is essential in a leak tight pipe. scanCONTROL laser scanners are therefore used during spiral welding to align the weld flanks. This results in a much more reliable welding process. The long base distance of 600mm and the protective housing for the sensor are also important here. |

Acquisition of the internal diameter of tubes

An important criterion for the quality or the wear of tubes in industrial applications is the dimensional conformance of the internal diameter over the complete length. Where high demands are made on accuracy, a quick and reliable recording of the data must be ensured, because, for example, wear measurements must be carried out in the chemical industry on pipes which are already installed, i.e. with the plant shut down. Two pairs of sensors record two tracks offset by 90° in one measurement step. |

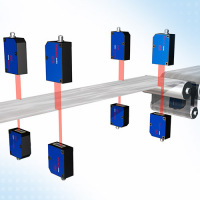

Strip width when trimming metal strips

As different widths are frequently required during the production of metal strips, the strips must be trimmed after the rolling process and both the cutters must be movable electrically. The distance is now measured by difference measurement using laser sensors from Micro-Epsilon so that compliance with the target dimensions no longer has to be checked manually as was the case previously. Two optoNCDT sensors are used for this. |

Weld seam tracking for pipeline inspection

Defective weld seams are often the reason for leaks on pipelines. Therefore, the seams are inspected on the outside after the welding with the profile scanner scanCONTROL. In doing so, the scanner is positioned in a testing device on the pipe. After the manual alignment, the scanner automatically inspects the weld seam and centers itself automatically on the pipe in doing so. |

High precision pipe measurement

High precision pipe measurement Pipes, fittings and sleeves are inspected using random sampling for their dimensional accuracy in a special system. Sensors of the optoNCDT 1700 series rotate mounted on a plate. The laser beam is deflected by 90° by an adjustable mirror for the measurement. The system produces a detailed thickness profile of the target using the difference method. |

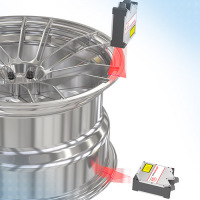

Aluminum rim dimension

Maximum quality is required for the production of aluminum rims so that the necessary smooth running is achieved in the subsequent use. In contrast to tactile methods, laser scanners from the Micro Epsilon scanCONTROL series are used for this. These sensors inspect the rims for all geometric defects in an integrated tester. Therefore, a 100% in-line quality control is achieved. |

Roller clearance

The distance of both rollers from each other or from the roller to the support surface is the crucial dimension for rolling processes for metals, plastics or other materials. In the case of sensitive processes and high material accuracies, the clearance must be checked constantly so that imminent rejection is avoided. The contacting inductive and the non-contact methods are suitable for this. In the case of contacting methods, the sensor is mounted on the outside on the roller guide. The change in clearance is transmitted to a plunger whose position change is measured by the inductive sensor. In the case of the non-contact method, the roller is between the transmitter and receiver of an optical micrometer. The emitted light curtain is partially covered by the roller. The remainder reaches the receiver through the gap. The gap can be calculated based on the light quantity measurement. |

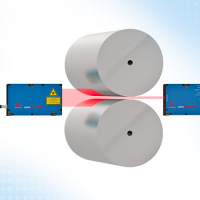

Coil edge

Rolled sheets in the metal industry are wound on coils for transport. It is important that directly before and also after the coiling, to check the position and the edge condition of the metal strip. optoCONTROL optical micrometers are used for this. If the edge of the coil is within the measuring range during the winding or unwinding, the position and the edge structure can be determined from this. This technique ensures that the coil is wound correctly and also that the correct metal strip quality has been delivered for the unwinding. |

Tempering - temperature measurement

Stresses can occur during induction hardening which can be counteracted by heating up again to the tempering temperature. However, temperatures lower than those used for hardening are involved. The temperatures are measured with pyrometers from Micro-Epsilon. |