Brake temperature measurement

Before an airplane can start, the temperature in the brakes must be below a certain limit. To determine the temperature, non-contact temperature sensors from Micro-Epsilon are used in the landing gear. |

Door lock detection

Before an aircraft starts, the doors are locked centrally. In order to determine the status of the locking, inductive displacement sensors from Micro-Epsilon are used. These detect the end position directly on the door lock. |

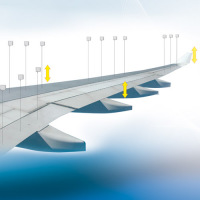

Reliable position recognition of the Wing-Tip-Brake

The so-called Wing Tip Brake sits on the shaft in the outer wing area. It avoids uneven extension of slats and flaps and uncontrolled movements of the buoyancy aids by external influences. Inductive displacement sensors from Micro-Epsilon detect the position of the brake shoes. |

Load tests on airplane wings

In order to optimize the behavior of wings during a flight, the wings are already subjected to vibration tests during the construction. 120 wireSENSOR draw-wire sensors are connected to the wing and synchronized. In this way, any change of the wing form in the vertical direction can be tracked. |

Position detection of car bodies in the processing line

Before a car emerges from a bodyshell, it passes through numerous stations within the production, in which fully automatic processing steps are carried out. In order to enables the processing robots to recognize the exact position of the car body, several laser triangulation sensors measure the car body and transmit the position data to the robot controller. |

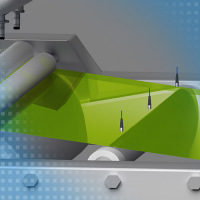

Measuring applied adhesive of tapes, plasters and Band-Aids

To ensure a homogeneous adhesive surface, capacitive displacement sensors measure the thickness of the adhesive on adhesive tapes and medical plasters. Capacitive sensors allow one-sided thickness measurement. Depending on the system structure, conductive or non-conductive adhesives can be measured. |

High precision thickness measurement of silicon wafers

Capacitive displacement sensors are used for the exact thickness measurement of wafers. Two opposing sensors detect the thickness and also determine other parameters such as deflection or sawing marks. The position of the wafer in the measuring gap may vary. |

Presence detection of small parts

In assembly processes, incoming components are inspected using Micro-Epsilon fiber optic sensors. Recognizing missing SMT components enables a smooth assembly process. Their flexible design allows for the optoCONTROL CLSK probe heads to be integrated in confined spaces. |

Thickness measurement of black rubber belts

Rubber mats for the structure sealing must exhibit a specified thickness for durability and tear resistance. The thickness of the films is measured directly after the extrusion. The optoNCDT 1750 sensors used measure the distance to the rubber despite poor reflectivity. The thickness is determined from the sensor signal and the distance to a reference roller. The user thus recognizes already starting deviations from the target thickness. |

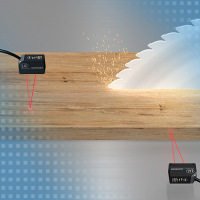

Orientation of wooden boards

In fully automated sawmills, the position of wooden boards before sawing must be determined so that they can be cut precisely. Micro-Epsilon laser displacement sensors detect the position of the boards from two sides and output the board position to the controller. |