Inspection of plate position

When printing woods with decors, optoCONTROL micrometers are used to control the positions of the plate. This prevents the printing head from colliding with the plate. These laser micrometers measure directly on wood and monitor the tools. |

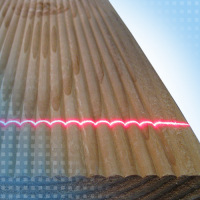

Inspection of wood floorboard relief

Laser scanners from Micro-Epsilon are used to inspect wood reliefs. They check the groove depth and provide reliable measurement results regardless of the type of wood. |

Profile inspection of parquet flooring and baseboards

Laser scanners from Micro-Epsilon are used for the profile measurement of parquet boards and baseboards. They inspect geometric characteristics such as groove height, gap dimensions and absolute dimensions to ensure homogeneous product quality. |

Color recognition of kitchen fronts

In order to ensure consistent color of different front panels, color sensors from Micro-Epsilon are used. The sensors inspect the color of the kitchen fronts in the painting plant. Color sensors ensure that the color shade is within the specified tolerances. Even the smallest color deviations imperceptible to the human eye can be detected reliably. |

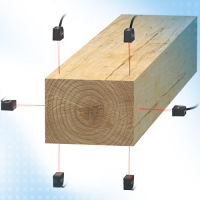

Dimension control of beams

For thickness and width measurement of plates, planks and beams, two optoNCDT laser sensors are used. If this arrangement is complemented by further sensors, one synchronized measurement process can combine the inspection of torsion with control of dimensions. |

Color inspection and sorting of supplier parts

Before installing front aprons, Micro-Epsilon color sensors check if the color of the attachment matches the body color. Different color groups can be defined to cover all coatings. |

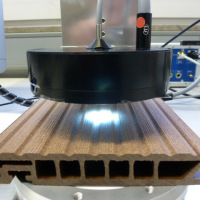

Color measurement of the floorboards

Plastic floorboards are made of colored granules and shaped by deep-drawing. After the production process, it must be guaranteed that the color of the floorboards is homogenous and that there are no color differences. |

In-line detection of protective film on PVC window frames

Company „Schüco“ manufactures PVC window frames. The PVC profiles are provided with a protective film after they are extruded. This film protects the frames from scratches and dirt. The colorCONTROL ACS7000 color measurement system checks if the protective film has been applied correctly. |

Calibrating robot axes

Industrial robots have become indispensable in modern production facilities due to their reliability and high speed. During set up and also at regular intervals within the scope of quality assurance, the robot axes must be adjusted. Here, electronic adjustment probes have already replaced mechanical probes. The measurement probes mounted on the robot axes acquire the zero point during the axis rotation using a probe tip. The integral electronics evaluates the probe signal and transmits a switching signal to the robot controller. |

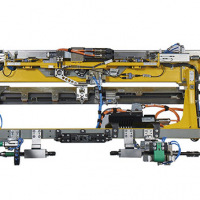

Laser profile scanner for cockpit assembly in cars

Fully or semi-automatic assembly of cockpit modules in the automotive industry requires the gripper tool to precisely position the assembly parts. As the laser scanners take over the measurement and positioning tasks, each cockpit module is individually adapted to the respective car body. Micro-Epsilon laser scanners are particularly suited for these measurement tasks due to their SMART functions and the particularly small and lightweight measuring head. They can be easily installed on a robot or manipulator. Using the SMART function, a parameterization of the sensors can be realized without further hardware components via Ethernet. In addition, measured values can be visualized and transmitted directly to the controller. The precise scanCONTROL laser profile sensor evaluates the complete profile internally and transmits the measurement values via Ethernet to the control system. This enables the actuators to change the axis positions on the gripper in order to assembly the cockpit module in the ideal position in the car body. After the cockpit is fixed, the sensor determines the installation position of the cockpit which serves as proof of quality for each vehicle. For the entire process including the fitting of the cockpit, an extremely short cycle time of less than one minute is required. Measuring independent of surface conditions, the sensors provide reliable measurement values whether bright or dark paints are used, different gloss levels, variable surface structures and in unsteady ambient light conditions. The sensor automatically readjusts the exposure. |