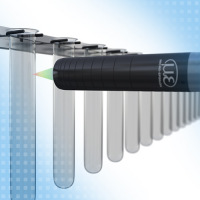

Roundness of bottles

With the roundness measurement of container glass, a fast measuring rate is required in order to support the ongoing process. Confocal chromatic sensors from Micro-Epsilon are used for thickness measurements in the star wheel while providing high measuring rates and accuracy in order to ensure reliable operation. |

Plunger stroke in IS machines

For 24-hour operation in the glass production involving more than 5 million measuring cycles pear year, Micro-Epsilon has developed an inductive EDS displacement sensor. This sensor determines the exact plunger position in IS machines and allows for the production to be carried out according to predefined specifications. In order to increase resistance to lubricants and shock loads, the entire sensor and electronics are now welded into a tight stainless steel housing. |

Color measurements of glass shades

The color is the crucial and visually distinctive feature of glass products. This is particularly true with natural and recycled raw materials based on varying compositions, where continuous and objective control of the color effect is an essential prerequisite for consistent quality. The ACS3 transmission sensor from Micro-Epsilon is used to inspect the glass colors and shades continuously. |

Planarity and thickness of display and flat glass

For the production of display glass, glass sheets with consistent thickness are required. The production process is regulated based on the measured results. Confocal chromatic sensors from Micro-Epsilon are used to detect the thickness from one side. Due to their high measuring rate, the sensors are also applied in high speed processes. When the sensors operate in a traversing manner or in several tracks, the planarity of complete sheets can be documented. |

Thickness of glass coatings

Glasses are often reinforced with safety and security films which provide increased splinter protection. In order to measure the film layer and to determine the thickness of the applied adhesive, confocal chromatic sensors from Micro-Epsilon are used. These measure the thickness of the finest of layers from one side. With one measurement, the thickness of the glass, film and the applied adhesive can be determined. |

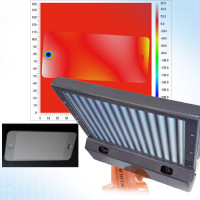

Surface inspection of display glass

Fully-automatic defect detection on shiny surfaces is based on deflectometry systems. Extremely small inclusions or defects are detected reliably. |

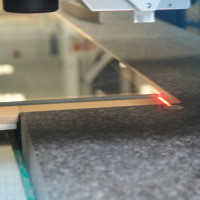

Edge measurement of glass

In many handling processes, precise positioning of glass sheets is required. The position of the sheets is determined via the detection of the glass edges. Laser profile sensors from Micro-Epsilon measure the edge position at several points and transmit this information to the control system. |

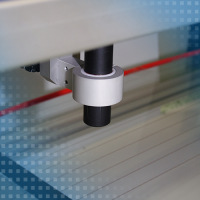

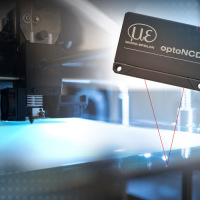

Distance control of print heads for glass printing

When printing on materials such as glass and ceramics, very fine detailed structures are applied on the carrier material, which requires precise positioning of the print head. For distance measurements, optoNCDT 1420 laser triangulation sensors from Micro-Epsilon are used. With a measuring range of 10mm, these determine at various points in the print head the respective distance from the surface to be printed. The data obtained enables the determination of the edges and the surface tilt and therefore the exact positioning of the print head. |

Non-contact temperature measurement when shaping container glass

In container glass production, the process relevant temperature must be inspected at different points. Non-contact temperature sensors are used during the shaping process that involves temperatures in excess of 500 °C. As the shaping process lasts for just a few seconds, the sensor response time is critical. During both the forming process of the parison and the final shaping process, the heat treatment of the glass can be influenced either by directly measuring the glass surface or by indirectly measuring the surface of the forming tool. At the end of the production process, the glass is tempered again to reduce the stress in the container. Therefore, the glass is heated again and then cooled for a period of up to 30 minutes in a cooling tunnel. When the containers leave the heating zone, the cooling process is monitored using non-contact temperature sensors. |

Bottom thickness measurement of container glass

With the wall thickness and roundness measurements in star wheel inspection machines, a fast measuring rate is required in order to support the ongoing process. Micro-Epsilon’s confocal chromatic measuring systems provide a high measuring rate and fast exposure time control. This also enables the measurement of thickness when the glass colors vary. |