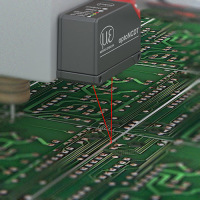

Measuring the coplanarity of IC pins

In SMT and reflow soldering processes, the coplanarity of the pins has to be inspected in order to assure a perfect soldering quality and to avoid failures. For this purpose, laser profile sensors from Micro-Epsilon are used. The scanner uses a blue laser diode which enables extremely high resolutions. |

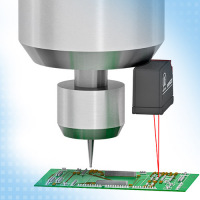

Print head positioning in laser transfer printers

With printing and exposure processes, the exact height of the print head or the distance from the object to be printed are crucial factors for the quality of the final product. Fast distance measurements with compact laser sensors from Micro-Epsilon enables fast readjustment and, in addition, edge detection. |

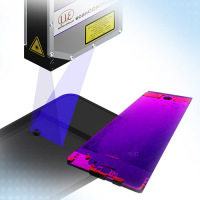

Dimensional inspection of fine mechanical structures

In assembly processes of smartphones and tablets, the dimensions and the assembly gap of the gasket are inspected in order to ensure high resistance to water and dust. Measurements are performed with Micro-Epsilon laser profile sensors that provide high resolution and profile frequency. |

Presence monitoring of electronic components

Laser triangulation sensors are used in fully automatic presence inspection of components on printed circuit boards. Very small details can be detected reliably due to the small light spot. The high measuring rate enables testing in the shortest cycle times. |

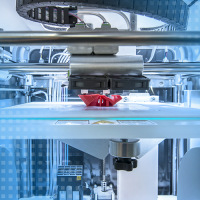

Distance measurement in dispensers for adhesives

In order to keep the adhesive dispenser always at the correct working distance, this distance value must be inspected continuously. For this purpose, compact laser sensors from Micro-Epsilon are used. Thanks to the fast measuring rate and the insensitivity to changing surface types, they continuously provide information about the distance of the glue dispenser. |

Color recognition in component sorting tasks

Particularly with automated mounting, components must be sorted according to their color. The colorSENSOR CFO is ideally suited for these high production speeds. Adjustable colors and tolerance enable high flexibility. |

Measuring scribe lines on PCB panels

Scribe lines are pressed into printed circuit boards for separation purposes. Laser sensors inspect the line depth which should be consistent in order to ensure reliable separation. |

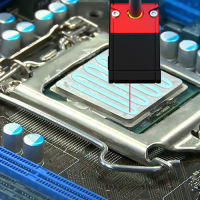

Heat conducting paste application

During the fully automatic application of heat conducting pastes, the correct dosage is a decisive factor. An overdosage of heat conducting paste impairs the thermal resistance, too little paste leads to thermal overload. The height of the paste bead is therefore detected using a laser triangulation sensor. |

Measuring the solder-wave height on wave soldering machines

When soldering printed circuit boards in wave soldering systems, the height of the solder wave is an important criterion for the quality of the solder joints. The level of the soldering tin is detected directly above the solder wave using an eddyNCDT displacement sensor. The influence of the solder pot level and the pump contamination is thereby compensated for. |

Mobile oscillation measuring system for wind turbines

Test, inspection and certification authorities offer mobile oscillation measuring systems for wind turbines without permanently installed Condition Monitoring Systems. They are used for prototype plants in the development phase, for production and construction supervision, as well as for measurements during operation. In mobile vibration measurement systems, high-precision and temperature-stable acceleration sensors from Micro-Epsilon are used. The acceleration sensors provide precise information about vibrations that can occur, for example, at the rotor, tower or generator. |