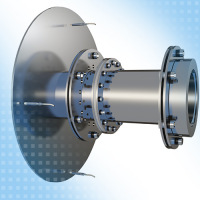

Measuring the deflection of the clutch disc

Eddy current displacement sensors measure the axial, radial or tangential deflection of the clutch disc. These robust sensors are designed for harsh ambient conditions and, due to their extremely compact size, can also be integrated in restricted installation spaces. The sensor provides stable measurement results despite high pressures and temperatures. |

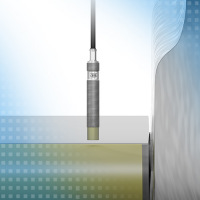

Measuring the temperature of frictional heat on bearings

The gearbox temperature in wind turbines is measured continuously during operation. Heating up of components may indicate a potential problem with a component. If a certain threshold is exceeded, subsequent remedial action can be started or maintenance planned. |

Oil gap measurement in shafts

With regard to predictive maintenance, the oil gap should be measured, i.e. the distance between the bearing surface and the shaft filled with lubricants. Despite pressure, high temperatures and lubricants, robust eddy current sensors from Micro-Epsilon can provide a permanent statement about the lubricating gap based on high measurement accuracy. |

Presence monitoring and identification of bottles

Laser scanners from Micro-Epsilon are used for high speed and fully automatic inspection of empty containers at bottlers and breweries. For this application, the Micro-Epsilon agent Tipteh has designed a test system based on laser line triangulation, which is used when the bottle crates are received. This inline system is equipped with five scanCONTROL 2900-50 laser line triangulation sensors from Micro-Epsilon. The crates are conveyed on a belt and scanned from above. Each scanner measures a row of bottles in the crates. Presence monitoring is carried out at conveyor speeds of up to 850 mm/s. The scanner uses the respective bottle height to determine whether the correct type of bottle is in the crate. The bottle height must not deviate more than 3 mm from the target height of the respective bottle type. Compared with a solution based on conventional image processing systems, laser scanners from Micro-Epsilon not only monitor bottle presence but also bottle height. In addition, logged data for subsequent statistics, evaluations and process optimization can be acquired. |

Marking detection on cosmetics bottles

Before the printing process, a reference mark is embossed into the bottles. Due to the depression of the embossment, the color of the reference mark deviates slightly from the rest of the bottle surface. The colorSENSOR CFO100 detects this minimal color difference, which enables the exact determination of the printing position below the embossment. For a flawless print, accurate and reproducible positioning is crucial. If the marking is missing, the bottle is considered as faulty and will be rejected immediately. Therefore at the same time, a good / bad evaluation can be carried out as part of a quality control. A machine turns the cosmetics bottle while the colorSENSOR CFO100 constantly measures the surface of the bottle at a distance of less than 10 mm. The embossment is detected quickly and reliably. Next, the exact position for the bottle printing is determined and further process steps can be carried out. The colorSENSOR shows clear advantages over other measuring methods. First, it masters the semi-transparent surface easily. Second, it is ideally suited to this kind of position measurement task due to its favorable price/performance ratio. |

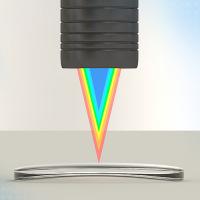

Measuring the curvature of lenses

In order to meet production tolerances, the contour of optical lenses such as eyeglass lenses or objectives, confocal chromatic sensors are used. Based on the distance values, statements about the surface properties can also be made. The sensors enable a large tilt angle which means they can also detect highly curved surfaces. |

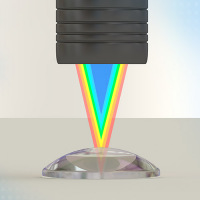

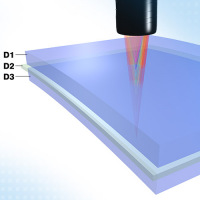

Measuring the center thickness of lenses

In order to meet production tolerances, the center thickness of optical lenses such as eyeglass lenses or objectives is measured using confocal chromatic sensors. The measurement is performed from one side and can also be carried out with very thin lenses. |

Wall thickness measurement of container glass

With the wall thickness and roundness measurements in star wheel inspection machines, a fast measuring rate is required in order to support the ongoing process. Micro-Epsilon’s confocal chromatic measuring systems provide a high measuring rate and fast exposure time control. This also enables the measurement of thickness when the glass colors vary. |

Temperature monitoring from the melting material to the cooling process

After the tin bath, flat glass has a temperature of approx. 600 °C. At the transition to the cooling zone and in the other subsequent cooling zones, thermoIMAGER infrared cameras are used for temperature inspection. Infrared cameras enable non-contact temperature monitoring of the cooling process from a safe distance to the glass. Thanks to the TIM Connect Software, the thermoIMAGER cameras can also be used as line scan cameras. The software enables the user to choose any line from the detector array and to position it. |

Gap monitoring of safety glass

For quality control and process control during the production of safety glass, confocal chromatic displacement sensors with a multi-peak function are used. Confocal chromatic sensors from Micro-Epsilon enable thickness measurements to micron accuracy. confocalDT sensors detect up to 5 layers by evaluating 6 measurement values on the boundary areas. |