Temperature measurement of molten metal

Temperature monitoring of liquid metal is important to maintain the corresponding process temperature during casting. With the thermoIMAGER TIM M05, Micro-Epsilon offers the right spectral range as well as a continuous measuring range of from 900 °C to 2000 °C. Due to the high frame rate of 1 kHz and the high optical resolution, thermal images can be recorded quickly and reliably. |

Temperature measurement in the hot rolling mill

In the milling line, the forming temperature between the individual rolls is measured continuously. Micro-Epsilon's non-contact infrared pyrometers measure with a short response time and from a safe distance. For the different metals and temperature ranges, IR temperature sensors and thermal cameras with different wavelengths are available. |

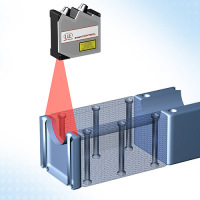

Weld seam profile

Welding robots which perform the joining automatically are often used for joining metals. For visible parts, the weld seam must satisfy certain optical criteria; for example, there must be no remaining welding beads. A laser scanner is installed directly after the welding head for this. It measures all the weld seams made and arranges for the robot to make corrections if necessary. |

Aluminum thickness

It is important to know the thickness of the plates for the manufacture of aluminum plates. The non-contact profile measuring system measures the profile of the plates using a capacitive sensor. At the same time, the width of the plate is determined during the measurement. The reversing rolling stand and the following roller stands can be better adjusted using the data obtained. The system is integrated in the existing roller track. Installed directly before the cropping shear where the plate is stationary for the cut, the production process is not impaired. |

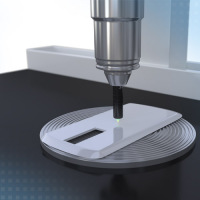

Coordinate measuring machine

In order to measure a wide variety of components, coordinate measuring machines are used. Different gauges and measuring devices provide a 3D image of the surface component. scanCONTROL laser line scanners are ideally suitable for this purpose. Based on the triangulation principle, they measure the actual component surface without contact to micrometer accuracy. |

Calibrating robot axes

Industrial robots have become indispensable in modern production facilities due to their reliability and high speed. During set up and also at regular intervals within the scope of quality assurance, the robot axes must be adjusted. Here, electronic adjustment probes have already replaced mechanical probes. The measurement probes mounted on the robot axes acquire the zero point during the axis rotation using a probe tip. The integral electronics evaluates the probe signal and transmits a switching signal to the robot controller. |

Coordinate measuring machine

Coordinate measurement machines from Zeiss have been known for decades for the highest quality, precision and reliability. Also the mobile measurement machine, ScanMax fulfills these criteria, in part due to the application of inductive displacement sensors from Micro-Epsilon. |

3D inspection and surface assessment of roof tiles

The production of roof tiles places high demands on measurement and testing methods for ensuring constant high product quality. In the DASTOKON semi-automatic measurement and test system and in the BSPK pilot plant a laser triangulation sensor of the Series ILD 1800 is used for the 3D inspection and for surface assessment. |

Coordinate measuring machine

Coordinate measurement machines are used for measuring many different components. Different scanners and measuring equipment measure the surface of the component in three dimensions. Laser line scanners are ideally suited for this purpose. They measure the actual surface of the component without contact and with micrometre precision according to the triangulation principle. |

Reduced risk of tipping with loading wagons

In order to increase the safety of loading wagons, automatic braking systems are used. The brakes are activated if the lateral acceleration of a loading wagon becomes too high due to high speeds and tight curves and if the wagon threatens to tip over. The braking reduces the wagon’s speed and therefore both the lateral acceleration and the risk of tipping over. For electronic braking systems, acceleration sensors from the ACC53 series from Micro-Epsilon are used, which reliably detect the accelerations of the loading wagon. |