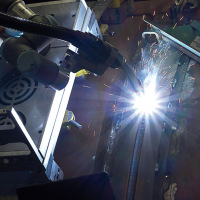

Optimizing weld seams with profile measurements

Inrotech A/S in Denmark relies on sensors from Micro-Epsilon to achieve optimal quality of weld seams in a fully automatic process. The company has developed a welding robot called »Inrotech-Crawler« which calculates welding processes in advance before carrying them out. Therefore, the robot uses the precise measurement values provided by the powerful laser profile scanner from Micro-Epsilon. A scanCONTROL 2900 scanner is fixed on the Inrotech-Crawler and detects the geometry of the seam to be welded before the actual welding process starts. Only these high precision profile measurements enable the process to be automated. Due to its compact, lightweight design with integrated controller, the laser profile scanner is ideally suited to this measurement task. Various connection possibilities offered by the SDK (Software Development Kit) enable the customer to directly transmit the profile data calibrated to their own software via scanCONTROL DLL. The Weldlogic technology from Inrotech then calculates, among other things, the number of welding passes, the position of the weld seams, the weld speed and the oscillation width. Directly after the calculation, the Crawler automatically performs the welding process. |

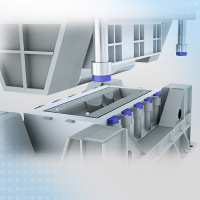

3D measurement of components prior to plasma cutting

In order to process these huge domes quickly, fully automatically and at extreme precision, it is necessary to determine their shape and exact position within the production line. As the pure CAD data of the dome often differs by several centimeters from the actual dimensions, the 3D profile of the covers is measured before processing using scanCONTROL 2900 laser scanners. The exact dimensions are then determined from the 2D data generated by the scanner which is connected to a 6D scanner position system. The scanning process is performed at high speeds up to 60 m/min. Therefore, a reliable hardware trigger is required to obtain the real shape of the target. Its compact design, integrated electronics and speed make the MicroEpsilon laser scanner suitable for inline integration. In addition, high performance scanners achieve a high repeatability of 50 µm/m even with different reflective properties of the metallic test objects. |

Bending/smoothness of aluminum cast covers

After AL covers have been cast and prior to milling of the sealing surface the covers must be manually straightened and sorted into OK/NOK. This operation takes place in a rough environment (casting bay). The measuring technique that was used earlier (probes) are subject to a high degree of wear and had to be replaced in regular intervals. In order to minimize spare parts costs the customers have decided in favor of the non- contacting and non-wearing eddy-current measuring system. What is of special importance for the success of this measuring method is the fact that eddyNCDT eddy-current sensors, due to the possibility of 3-point-linearization, supply reliable measuring values even with complex target geometries. |

Monitoring mold deformations in aluminum die-casting

Monitoring tool deformation using inductive sensors based on eddy current enables high product quality combined with improved tool life and reduced rework. Usually, three to four eddyNCDT 3005 eddy current systems are used to ensure consistent gap monitoring. A system consists of a compact and robust controller, which together with the cable and sensor form a solid unit. The integrated system design increases robustness and resistance to external factors, making the system insensitive to harsh industrial environments with high temperatures, dust, dirt or pressure, and delivers accurate results regardless of the environment. Due to the compactness of the eddyNCDT 3005 system, subsequent integration into an existing machine is possible at any time. |

Monitoring metal sheet infeed during the pressing process

The measurement of the distortion is carried out using several optoNCDT 1420 laser triangulation sensors, which are placed around the metal sheet, either in the tool or on the side of the tool. The arrangement is chosen in such a way that the laser beam measures on the edges of the sheet, which is between the top and bottom of the tool. Due to the extremely small measurement spot size, the laser is therefore able to measure extremely small gaps between the two tool parts of less than one millimeter. The measured values are transmitted via analog or digitally to the controller. They allow a conclusion to be drawn on how much material has flowed. This enables, for example, the pressing force to be controlled during the ongoing process, reducing waste, material consumption, downtime and costs. Micro-Epsilon laser triangulation sensors are rugged and can withstand high mechanical loads such as vibration and shock. |

Coil diameter

Rolled strips in the metal industry are wound on coils for transport. For the later processing when the coils are unwound, it is important to know how much material has already been unrolled. This task is simple to solve by using an optoNCDT ILR optical length sensor. It continuously measures onto the surface of the coil and thus records the diameter. The diameter of the coil reduces due to the unwinding which is measured using the increase in distance from the coil surface to the sensor. Using the coil thickness, the material length can be recalculated using specific algorithms. |

Coil unwinding

Rolled strips in the metal industry are wound on coils for transport. For the later processing when the coils are unwound, it is important to know how much material has already been unrolled. This task is simple to solve by using an optoNCDT ILR optical length sensor. It continuously measures the distance from the surface of the coil to the center. The thickness of the coil reduces due to the unwinding which is measured using the increase in distance from the coil surface to the sensor. Using the coil thickness, the material length can be recalculated using specific algorithms. |

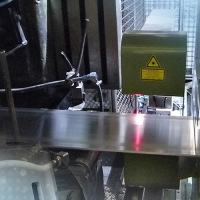

Measuring and inspecting laser welding seams

Fully automatic welding units can be found in numerous industrial areas. Quality control in the form of a 100% inspection is indispensable in order to achieve defect-free weld seams. Laser profile sensors from Micro-Epsilon monitor the weld seam and immediately detect defects as well as the completeness of the width and height profile of the weld. |

Double sheet detection before pressing

Before shaped sheets are fed into the press, laser-optical displacement sensors are used, which enable double sheet detection. Two sensors are mounted above and below the continuous sheets and provide a thickness value regardless of the exact position of the sheets. |

Thickness measurement of metal strips

When measuring the thickness of metal strips, optical methods based on laser triangulation have numerous advantages compared with other methods. They measure without contact and therefore without wear. Moreover, independently of the condition of the material it is possible to carry out an exact geometrical measurement in relation to the strip surface. Micro-Epsilon offers robust measuring systems as C-frames and O-frames which operate independently of the alloy. |