Food Supplement Batch Tank Radar Level Sensor_________________________________________________________________

When a Midwest manufacturer of protein drinks needed reliable level measurement of their batch mix tanks, they turned to Flowline. The firm blends base liquid and powder supplements into custom nutritional products for professional and collegiate sports teams. The mixing process is level and time measured as operators manually fill each tank with batch ingredients. During which, the media surface is agitated in liquid or slurry form, and the air gap above the media is clouded with dusty powder. Requiring non-contact level measurement, the operator previously installed ultrasonic sensors. They worked fine until the powder and resulting dust attenuated their acoustic signal. For this reason, Flowline suggested the use of our radar sensors that measure through airborne powder. The radar sensor provides continuous level data to the PLC, which monitors the tank and controls the mixer. Flowline is reliable level measurement. |

Water Treatment Chemical Tank Ultrasonic Level Sensor_________________________________________________________________

When Indiana American Water needed reliable level measurement of their chemical tanks, they turned to Flowline. The municipality provides water and wastewater treatment service to 1.3 million Americans, and reliable chemical automation is core to their mission. Aluminum chlorohydrate is an excellent coagulant that they broadly use in wastewater clarification and sludge dewatering applications. The aluminum salt based chemical is sticky, and it coats equipment and instrumentation with reckless abandon. Plant operators grew tired of repeatedly cleaning contact level sensors, and wanted a maintenance free level solution. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors. The ultrasonic sensors provide continuous level data to the SCADA, which monitors the tanks and alarms for replenishment. Flowline is reliable level measurement. |

Foaming Neutralization Tank Radar Level Sensor_________________________________________________________________

When a Northeast AgroScience company needed reliable level measurement of their wastewater neutralization tanks, they turned to Flowline. The company supplies crop protection nutrients and livestock inoculants that sustain and increase the product yields of their farming customers. At their manufacturing plant, calcium carbonate is steadily dosed into their stage one wastewater treatment tanks, and the chemical foams when agitated. During which, the operators had experienced intermittent measurement from ultrasonic level sensors, due to the absorption of their acoustic signals. For this reason, Flowline suggested the use of our radar sensors, that are unaffected by foaming media. The radar sensors provide continuous level data to the PLC, which monitors the tanks and controls the pH. Flowline is reliable level measurement. |

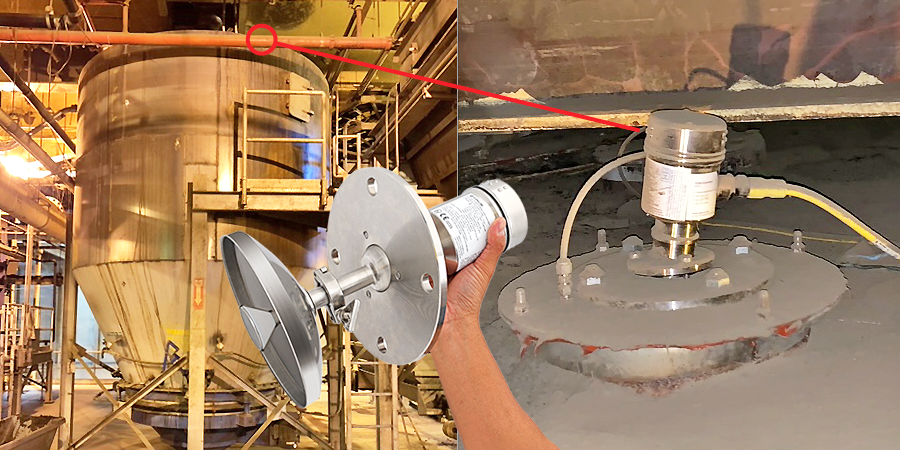

Biosolids Dusty Powder Silo Radar Level Sensor_________________________________________________________________

When a Texas wastewater treatment plant needed reliable level measurement of their biosolid silos, they turned to Flowline. The plant dewaters sludge to cake, and further processes the cake to powder using a digester heat exchanger and vortex mixer. The nutrient rich powder is then stored onsite and sold to fertilizer companies who mix it into compost or pellets for resale to farms. With the consistency of cement powder, the media is very dusty, and it builds up on everything. Plant operators were tired of removing, cleaning and reinstalling a different radar level sensor that often became intermittent due to material build-up. For this reason, Flowline suggested the use of our radar sensors with high power parabolic antennas that are unaffected by build up, and ideal for dusty applications. The radar sensors provide continuous level data to the SCADA, which monitors the silos and alarms when full. Flowline is reliable level measurement. |

Restaurant Septic Tank Guided Wave Level Transmitter_________________________________________________________________

When a Texas restaurant needed reliable level measurement of their septic tank, they turned to Flowline. Greywater, cooking oil, soap and grease enter the tank daily, and depending upon business volume and leach field efficiency, the tank requires pumping 1-3 times per month. Like most operators, they’re focused on customers, not septic tanks and back-ups were inevitable. When it came time for a new septic system, reliable tank measurement was at the top their list, and they wanted a level sensor that performs in coating liquids. For this reason, Flowline suggested the use of our guided wave sensor with rod antenna, that’s unaffected by material build-up on the sensor. The guided wave sensor provides continuous level data to the indicator-alarm. Flowline is reliable level measurement. |

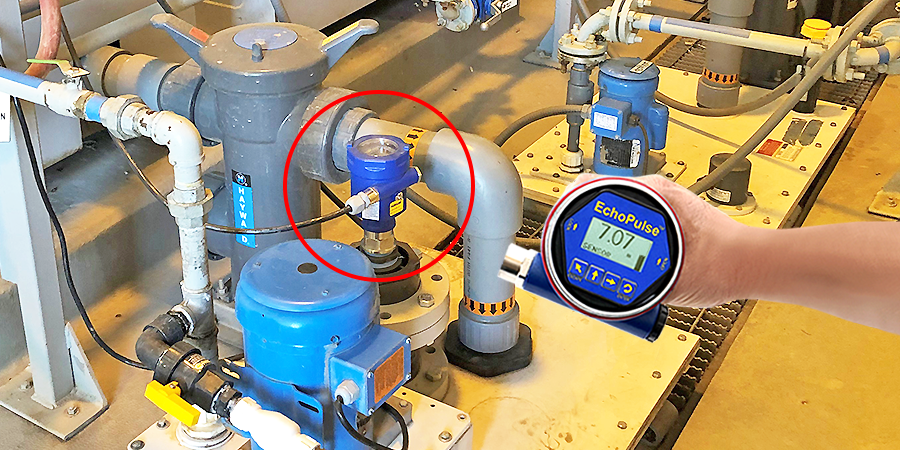

Food Sanitizer Chemical Feed Ultrasonic Level Transmitter_________________________________________________________________

When an Iowa food processing company needed reliable level measurement of their chemical feed tanks, they turned to Flowline. Food safety is their highest priority and the use of sanitizing chemicals is central to maintaining both food and equipment cleanliness. The plant runs three shifts a day, two shifts processing and one shift cleaning. During which, a foaming solution of peroxyacetic acid is sprayed on, brushed and then power washed off the processing equipment. Meeting this demand, requires a highly reliable chemical storage, feed and inventory management system. Level driven, the system integrator wanted corrosion resistant, non-contact sensors. For these reasons, Flowline suggested our ultrasonic sensors for the day tanks and radar sensors for the vaporous storage tanks. The ultrasonic and radar sensors provide reliable level data to the PLC, which monitors all tanks and controls the feed process. Flowline is reliable level measurement. |

Grain Truck Loading Silo Radar Level Transmitter_________________________________________________________________

When a Midwest farmer needed reliable level measurement of their grain truck loading station, they turned to Flowline. Harvested wheat kernels are stored in large silos awaiting purchase by and transportation to their local coop. In preparation, grain is transferred to three elevated loading silos that gravity feed into trucks waiting below. The operator monitors level indicators as each loading silo is filled and emptied. Unfortunately, their mechanical-type level bobbers would often fail, requiring costly and dangerous maintenance. For this reason, Flowline suggested the use of our solid-state radar sensors that provide reliable, maintenance-free level measurement. The radar sensors provide continuous level data to the silo indicator panel. Flowline is reliable level measurement. |

Portable Bulk Storage Tank Radar Level Transmitter_________________________________________________________________

When a Texas semiconductor manufacturer needed reliable level measurement of their temporary wastewater storage tanks, they turned to Flowline. Chip production was soon to expand beyond their capacity to store, treat and recycle the resulting wastewater. The company purchased additional treatment skids and leased temporary storage tanks from Rain for Rent. In those tanks, the facility required a hazardous, corrosion resistant level solution that works with foam and vapor. For these reasons, Flowline suggested the use of our intrinsically safe radar sensors that are unaffected by difficult or changing process conditions. The radar sensors provide continuous level data to the PLC which monitors the tanks and controls the treatment process. Flowline is reliable level measurement. |

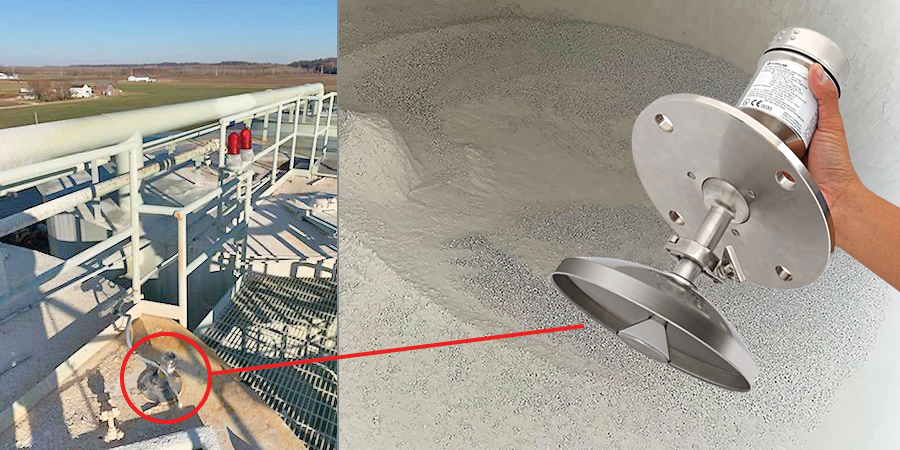

Municipal Lime Powder Silo Radar Level Measurement_________________________________________________________________

When a Mississippi municipality needed reliable level measurement of their caustic lime silos, they turned to Flowline. Lime powder is added to mix tanks, slaked into slurry batches and applied in pH neutralization and coagulation. This is their most used chemical and the water treatment plant shuts down without it. Lime powder is difficult to measure as it’s very dusty and it quickly coats everything in the silos. Plant operators were dissatisfied with a different radar level sensor brand, because those sensors required frequent removal and cleaning. For this reason, Flowline suggested the use of our radar sensors with high power parabolic antennas that are unaffected by buildup, and ideal for dusty lime silo applications. The radar sensors provide continuous level data to the SCADA which monitors the silos and alarms for lime replenishment. Flowline is reliable level measurement. |

Glycol Dehydration Skid Tank Guided Wave Level Measurement_________________________________________________________________

When a US energy company needed reliable level measurement of their glycol dehydration skids, they turned to Flowline. When natural gas exits a well, it typically contains water that can damage downstream processes and equipment. To combat this, a glycol dehydration system is used to absorb and separate the water from the gas stream. Level measurement of the glycol supply and condenser tanks is critical, and the company remotely monitors these skids. The operator used a different guided wave level sensor brand, and was dissatisfied with its high cost and programming complexity. For this reason, Flowline suggested the use of our guided wave sensor that saved them considerable money in product, and time in setup with our free WebCal configuration software. The guided wave sensors provide continuous level data to the SCADA, which in turn, monitors the tanks and controls the process. Flowline is reliable level measurement. |