Marine Aquarium Reservoir Radar Level Sensor_________________________________________________________________

When a Pacific Northwest marine aquarium and mammal rehabilitation center needed reliable level measurement of their saltwater reservoir, they turned to Flowline. Located on the coast, their exhibit and treatment pools are replenished from an underground reservoir that’s frequently refilled with bay water. During which, the high agitation generates surface foam that caused their previous ultrasonic liquid level sensors to go lost due to signal absorption. For this reason, Flowline suggested the use of our pulse radar liquid level sensors that are unaffected by foam or agitation. The pulse radar sensor provides reliable level data to the PLC, which in turn, monitors the reservoir level and controls the transfer pumps. Flowline is reliable level measurement. |

Corrosion Resistant Plating Ultrasonic Level Sensor_________________________________________________________________

When Zimmer of Indiana needed reliable level measurement of their nickel electroplating lines, they turned to Flowline. As a manufacturer of hip and knee replacement joints, the finish quality and tolerances of their plated parts are critical. Their previous float level switches would periodically fail due to corrosion attack, resulting in significant scrap loss. For this reason, Flowline suggested the use of our non-contact, ultrasonic level sensors that are packaged in corrosion resistant PVDF. Each ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the bath levels and actuates a valve to systematically refill each bath. Flowline is reliable level measurement. |

Dairy Foaming Waste Sump Radar Level Sensor_________________________________________________________________

When DairiConcepts of Missouri needed reliable level measurement of their foaming waste sumps, they turned to Flowline. A leading manufacturer of cheese, their wastewater streams include thick foam and sticky particulates with the inclusion of steam and chemicals during the cleaning process. Needless to say, their waste sump applications are challenging and the company was dissatisfied with their previous float and pressure level sensors that required weekly cleaning. For this reason, Flowline suggested the use of our non-contact, pulse level radar sensors that are unaffected by foam or steam. The pulse radar sensor provides reliable level data to the PLC, which in turn, monitors the sump level and controls the pump to transfer the content into wastewater treatment. Flowline is reliable level measurement. |

Sewer Pump Lift Station Radar Level Sensor_________________________________________________________________

When a Southern California municipality needed reliable level measurement in their sewer pump lift stations, they turned to Flowline. Over the years, the operators had used float level switches and ultrasonic level sensors in their lift stations with limited success. The float switches required ongoing maintenance due to grease build-up, and the ultrasonic sensors would go lost every time foam entered the sump due to signal absorption. For this reason, Flowline suggested the use of our pulse radar liquid level sensors that are unaffected by wastewater variables such as grease or foam. The pulse radar sensor provides continuous level data to the SCADA, which in turn, monitors the sump level and controls the two submersible pumps. Flowline is reliable level measurement. |

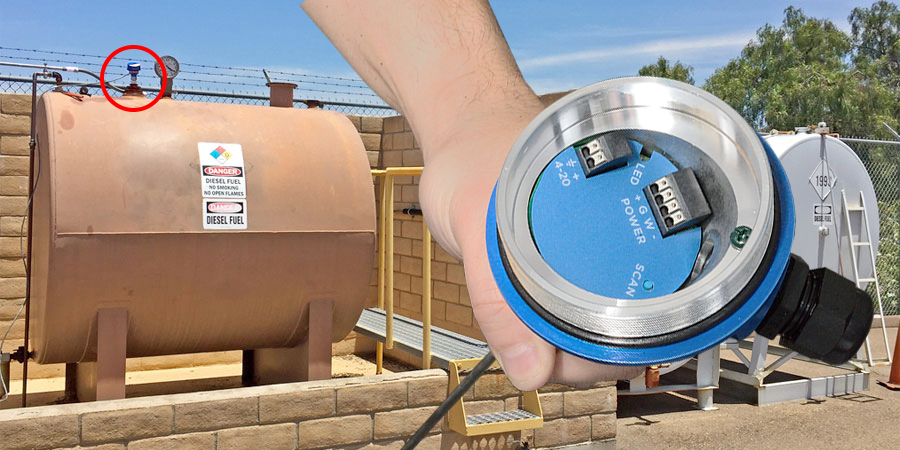

Municipal Diesel Generator Guided Wave Level Sensor_________________________________________________________________

When a Southern California water district needed reliable level measurement of their diesel storage tanks, they turned to Flowline. Eight of their pump lift stations are remotely located and generators are required for emergency back up power. Each generator has a 2,000 gallon diesel tank, and the level in each tank is monitored to schedule truck resupply. Their previous float level transmitters were unreliable because the floats would often become stuck in the high level condition. For this reason, Flowline suggested the use of our guided wave radar sensors which are unaffected by the coating characteristics of fuel oil. The guided wave sensor provides continuous level data to the SCADA, which in turn, reports resupply and alarm conditions to the municipal operators. The rugged sensor is constructed of 316L with an aluminum enclosure, and is ideal for metal tank applications. Flowline is reliable level measurement. |

Municipal Water Reservoir Radar Level Sensor_________________________________________________________________

When Spartanburg Water in South Carolina needed reliable level measurement of their reservoir, they turned to Flowline. Fed by Lake Blalock, Hogback and Vaughn creeks, the Lake Bowen reservoir holds up to 6.3B gallons at full capacity, and reliable level measurement is critical to the water department and community they serve. The operators had experienced problems with their ultrasonic sensors during extreme wind events, and pressure sensors that would often clog in the muddy lake bottom. For this reason, Flowline suggested the use of our non-contact, pulse radar level sensors that are unaffected by environmental factors such as wind, and are available in general purpose or intrinsically safe versions. Mounted to the end of a platform, the pulse radar sensor provides reliable level data to the SCADA, which in turn, monitors the level and controls the water flow into and out of the reservoir. Flowline is reliable level measurement. |

Corrosive Oil Field Chemical Ultrasonic Level Sensor_________________________________________________________________

When a US chemical distributor needed reliable level measurement of their oil field chemical feed tanks, they turned to Flowline. Surface water and downhole fluids often combine into salty, brackish solutions that negatively affect well production and equipment. To address this, antiscalant chemicals are injected into the well to reduce salts and other contaminants. But they’re also corrosive, and over time the operators had experienced high failure rates with their pressure level sensors due to corrosion. For this reason, Flowline suggested the use of our non-contact, reflective ultrasonic level sensors that are packaged in PVDF, and feature our proprietary reflective technology that works in condensation. Each ultrasonic sensor provides reliable level data to the SCADA, which in turn, monitors the levels and transmits inventory data to a logistics center for truck routing and resupply. Flowline is reliable level measurement. |

Stormwater Pump Lift Station Radar Level Sensor_________________________________________________________________

When a Central California municipality needed reliable level measurement of their stormwater pump lift stations, they turned to Flowline. Pump stations collect run off from streets and highways, and transfer their contents into water treatment, reclamation or disposal. During extreme weather events, they become violent environments with fast rising level, lots of agitation and foam. Factors that can directly affect level measurement reliability, damaging submersible pressure sensors and causing ultrasonic sensor intermittence due to foam. For this reason, Flowline suggested the use of our pulse radar liquid level sensors that are mounted safely above the sump, and unaffected by foam. The pulse radar sensor provides continuous level data to the SCADA, which in turn, monitors the sump level and actuates the high speed pumps. Flowline is reliable level measurement.

|

HVAC Cooling Water Basin Ultrasonic Level Sensor_________________________________________________________________

When Hewlett Packard needed reliable level measurement of the water sumps in their data center, they turned to Flowline. Servers generate tremendous heat, and HVAC cooling systems are required to maintain operational temperature. The reliable collection and transfer of process water to and from the cooling tower is critical to the system, and the operators had experienced agitation and corrosion problems with their previous float level sensors. For this reason, Flowline suggested the use of our non-contact ultrasonic liquid level sensors, mounted in a stand-pipe to eliminate agitation. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the sump level and actuates the transfer pump. Flowline is reliable level measurement.

|

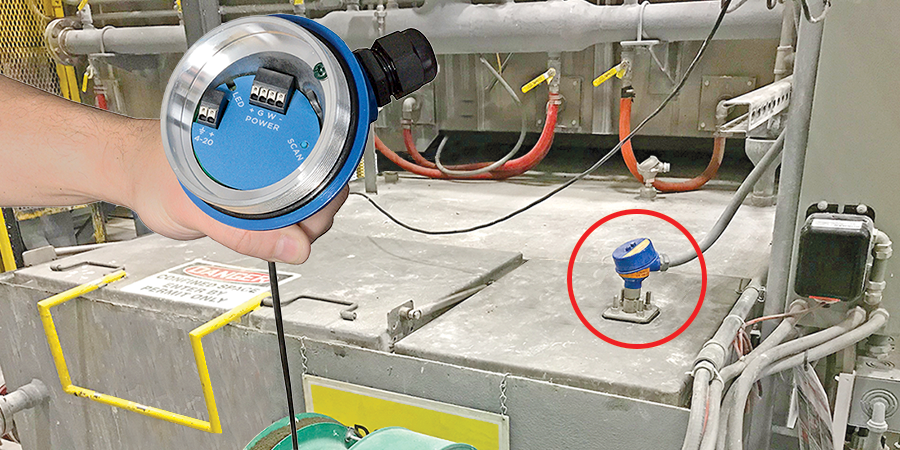

Chrome Plating Process Tank Guided Wave Level Sensor_________________________________________________________________

When an Ohio metal finishing and lamination manufacturer needed reliable level measurement of their chrome batch, plating and rinse tanks, they turned to Flowline. The company surface treats aluminum roll stock to customer specifications, and finish process quality and efficiency is vital to their business. The process is mildly corrosive, hot, condensing and foaming, and their operators had experienced ongoing problems with ultrasonic sensors. For this reason, Flowline suggested the use of our guided wave liquid level sensors that are unaffected by such process variables. Each guided wave sensor provides continuous level data to the PLC, which in turn, controls the batching, filling and emptying of the tanks. Flowline is reliable level measurement.

|