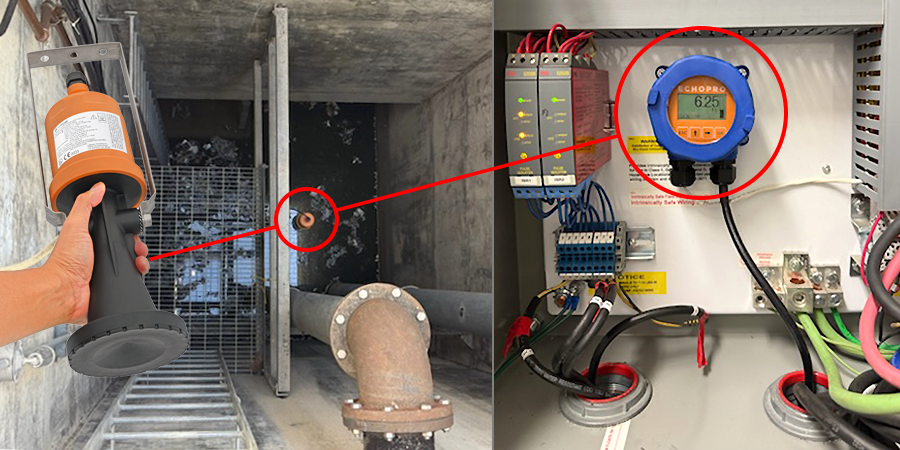

Stormwater Pump Lift Station Radar Liquid Level Measurement______________________________________________________ When a California municipality needed reliable level measurement of their large stormwater lift station, they turned to Flowline. Located under a freeway intersection, the pump station collects, holds and then transfers the stormwater run-off from eight multi-lane highway segments above. During peak rain events, the 60′ deep vault can receive a few thousand gallons per minute along with trash, road debris, chemicals and particulates. The IC&E manager said, “We’ve tried several level sensor types here, and they’ve all had reliability or maintenance issues. I need a reliable, non-contact level sensor that maintenance-free. Additionally, it must be intrinsically safe and configurable above ground so my team can quickly verify its function.” For these reasons, Flowline suggested our 26 GHz radar sensor that’s extremely reliable, and comes with a remote display for placement in their panel. The radar sensor provides reliable level data to the SCADA which monitors the vault and controls the two lead-lag pumps. Flowline is reliable level measurement. |

Geothermal HVAC Cistern Ultrasonic Level Measurement _________________________________________________________________ When a Northeastern high school needed reliable level measurement of their geothermal HVAC cisterns, they turned to Flowline. The open loop system pumps cistern groundwater through the buildings, where it either absorbs or transfers heat based on the temperature, and then recirculates it back to the cistern. A HVAC contractor determined that the cisterns did not have enough groundwater to support the required flow rates, and they had to be periodically refilled with well water. To do so, they needed to add level measurement, a fill valve and relay control to each cistern. Finally, the I&C engineer was concerned over condensation and turbulence in the cisterns. For these reasons, Flowline suggested our reflective ultrasonic level sensors that are unaffected by condensation, installed in a standpipe to dampen turbulence. The ultrasonic sensors provide reliable level data to the controllers, which monitor the cisterns and automatically refill them when low. Flowline is reliable level measurement. |

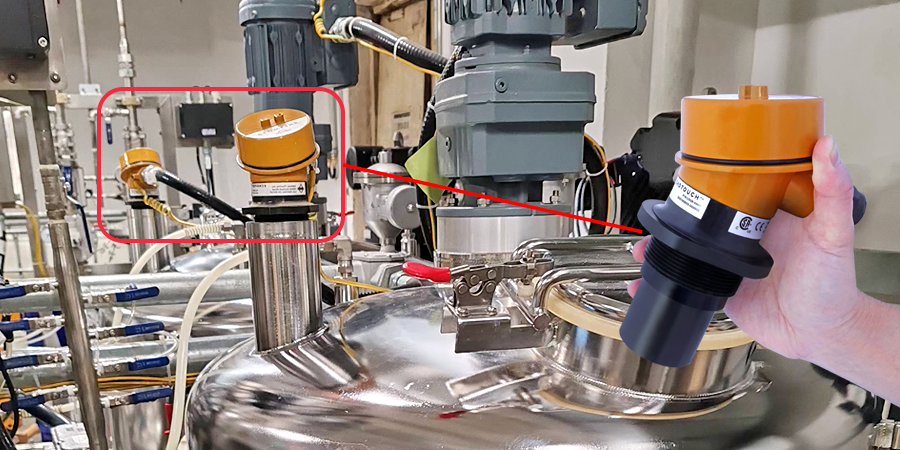

Automotive Paint Mix Tank Ultrasonic Level Measurement _________________________________________________________________ When a Pacific Rim automative manufacturer needed reliable level measurement of their paint mix tanks, they turned to Flowline. The company continuously batches, blends and pumps nine colors through twenty-seven mix tanks to their robotic spray lines. The acrylic polyurethane paint is viscous, coating and flammable, and it becomes very agitated during blending. The mix tank OEM required reliable, non-contact level measurement with intrinsic safety, a metal enclosure and push button display for sensor configuration. For these reasons, Flowline suggested our EchoTouch intrinsically safe ultrasonic level sensor. The ultrasonic sensors provide reliable level data to the PLC, which monitors each tank and controls paint batch make up and pump transfer. Flowline is reliable level measurement. |

Saudi Arabia Dam Radar Level Measurement_________________________________________________________________ When a Saudi system integrator needed reliable level measurement of their water dam project, they turned to Flowline. The kingdom is quickly running out of ground water and their spending billions on counter measures including desalinization plants, rainwater collection dams, and large underground piping and storage systems. While it doesn’t rain frequently, the storms can be torrential, and the dry soil typically flash floods into the valleys. There it’s a race to collect and pump the precious water into their underground network ahead of evaporation. Here a large dam sits idle awaiting rain to fill the reservoir. The I&C project manager required a long range, non-contact level sensor that’s reliable and unaffected by environmental factors including sun, wind, dust, rain and extreme turbulence. Further, the spec called for a metal enclosure and intrinsic safety, as this site is adjacent to a refinery. For these reasons, Flowline suggested our 26-GHz radar sensor that meets all such requirements. The radar sensor provides reliable level data to the SCADA, which monitors the reservoir and controls the pumps and spillway. Flowline is reliable level measurement. |

Parts Washing Machine Ultrasonic Level Switch_________________________________________________________________ When an Ohio metal manufacturer needed reliable level detection and switching of their parts washing machine, they turned to Flowline. They fabricate parts to order and the last step in their process is washing. During which, baskets are placed into a washing machine that sprays and rinses the parts in a solution of hot water, degreaser and acid. The solution passes through a filter and returns to the recirculation tank that feeds the sprayers. There the controls engineer wanted to replace the prior metal float level switches explaining, “Despite the filtering, the recirculation tank builds up residue, and eventually the floats stick, which causes false alarms and a maintenance shut down. Ideally, I’d like a non-contact level sensor with relay outputs to mimic the float level switch points. That way, I don’t have to reconfigure the hardware or programming on the PLC.” For this reason, Flowline suggested our EchoPod multi-function ultrasonic level sensor which has four programmable relays. The ultrasonic sensor provides reliable level switch inputs to the PLC, which monitors the recirculation tank and controls the parts wash cycle. Flowline is reliable level switching. |

Water Treatment Chemical Ultrasonic Level Measurement_________________________________________________________________ When a Midwest industrial water treatment firm needed reliable level measurement of their anti-corrosion, scaling and microbial feed tanks, they turned to Flowline. Their customer, a plastic parts manufacturer, injects water into their tool bodies to regulate the mold temperatures. When their parts through put declined, they realized the tools were running hot, and poor water quality was to blame. The water professionals assessed the problem, and designed a custom water treatment system using our small tank ultrasonic level sensors. When approaching empty, low level alarms are triggered, proactively notifying maintenance that it’s time to refill the tanks. The ultrasonic sensor provide reliable level data to the controller, which monitors the feed tanks and alarms for replenishment. Flowline is reliable level measurement. |