Sulfuric Acid Bulk Storage Radar Level Sensor________________________________________________________________

When a Midwest chemical distributor needed reliable level measurement of their sulfuric acid storage tanks, they turned to Flowline. In higher concentrations, sulfuric is exceptionally corrosive and vaporous. They had used a different brand of ultrasonic sensors with poor performance because the thick vapor was absorbing the acoustic signal, and causing the sensors to periodically loose track of the level. For this reason, Flowline suggested the use of our pulse radar sensors that are unaffected by vapor or corrosion. The pulse radar sensor provides continuous level data to the PLC, which in turn, provides inventory and safety alarms to the operators. The rugged sensor has a PTFE probe and coated aluminum enclosure for corrosive media. Flowline is reliable level measurement. |

Water Treatment Chemical Feed Ultrasonic Level Sensor______________________________________________________________________________________

When a California distributor of water treatment chemicals needed reliable level measurement of their dosing systems, they turned to Flowline. Anti-scalants are commonly injected into process feed water to disperse silica and prevent the build-up of scale that would otherwise damage equipment or dependent processes. The chemicals are sticky and their previous float type level sensors would often fail, requiring periodic cleaning by their truck drivers. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors that are unaffected by sticky or corrosive chemicals. The ultrasonic sensor provides continuous level data to the chemical feed controller, which in turn, displays the tank levels and actuates low level alarms for replenishment. Flowline is reliable level measurement. |

Chemical Blending Mix Tank Radar Level Sensor______________________________________________________________________________________

When a Wisconsin chemical distributor needed reliable level measurement of their mix tanks, they turned to Flowline. The company blends, packages and distributes acid and caustic solutions, and their chemical mix stations are critical to their business. But these are challenging applications with highly corrosive and vaporous media that’s agitated and foaming. As a result, their previous level sensors were unreliable and under constant replacement. For this reason, Flowline suggested the use of our pulse radar sensor that’s unaffected by corrosion, vapor, foam or agitation. The pulse radar sensor is mounted to the tank top and provides continuous level data to the PLC, which in turn, controls the batch filling and blending process. Flowline is reliable level measurement. |

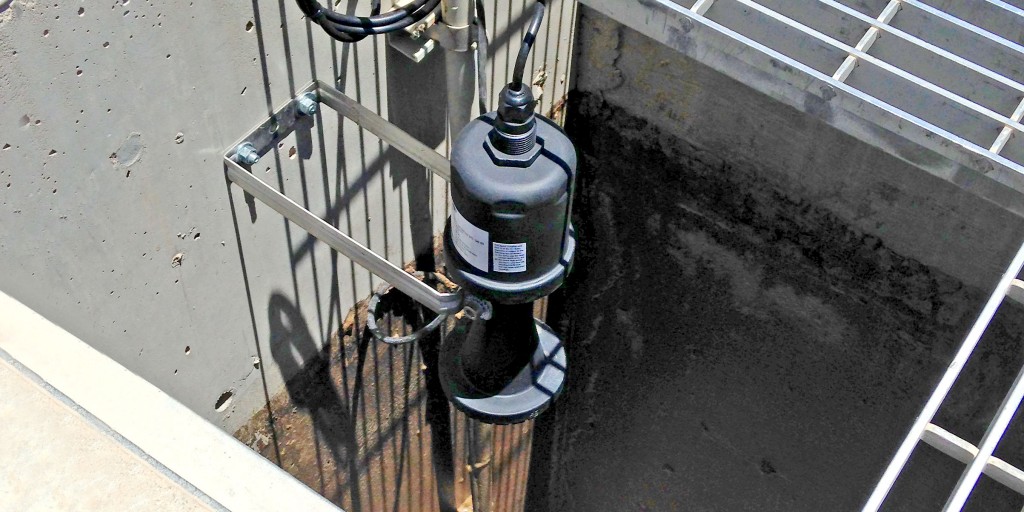

Stormwater Pump Station Radar Level Sensor______________________________________________________________________________________

When a West Virginia municipality needed reliable level measurement of their stormwater pump lift stations, they turned to Flowline. Pumping stations collect and transfer stormwater run off into water treatment, reclamation or disposal. But they also receive trash, dirt, plant material, grease, debris, chemicals and anything else you can imagine, making them very challenging applications. As a result, their submersible pressure sensors were often clogged and unreliable. For this reason, Flowline suggested the use of our non-contact, pulse radar sensor that’s unaffected by such variables. The pulse radar sensor is bracket mounted to the side wall and provides continuous level data to the SCADA, which in turn, controls the pumps. The sensor’s display provides convenient local indication. Flowline is reliable level measurement. |

Foaming Wastewater Aeration Tank Radar Level Sensor______________________________________________________________________________________

When a Colorado municipality needed reliable level measurement of their foaming aeration tanks, they turned to Flowline. Foam occurs in activated sludge processes and is a common operational problem for plant operators. It consumes reactor volume, decreases treatment efficiency and sticks to everything it contacts. Additionally the density, thickness and surface characteristics of foam are dynamic, and further complicating to reliable level measurement. For this reason, Flowline suggested the use of our pulse radar liquid level sensor that’s unaffected by foam and it’s variables. The pulse radar sensor is flange mounted above the aeration tank and provides continuous level data to the SCADA, which in turn, controls the treatment process. The sensor is unaffected by foam. Flowline is reliable level measurement. |

Marine Diesel And Greywater Ultrasonic Level Sensor______________________________________________________________________________________

When a California shipyard needed reliable level measurement for their customer’s diesel, water and greywater holding tanks, they turned to Flowline. Yacht manufacturers typically install float type magnetostrictive level sensors that fail over time due to material build-up, resulting in fuel shortages and greywater overflows. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors that are unaffected by sticky diesel or coating wastewater. The shipyard has since standardized on this solution and are now retrofitting 1-2 yachts per month. The ultrasonic sensor provides continuous level data to the multi-tank level controller, which in turn, displays tank levels and actuates high or low level alarms. Flowline is reliable level measurement. |

Laundry Chemical Day Tank Ultrasonic Level Sensor________________________________________________________________

When Dexter Laundry of Iowa needed reliable level measurement of their customer’s chemical day tanks, they turned to Flowline. Commercial laundries use considerable amounts of cleaning detergents and chemicals. These are delivered in bulk and distributed to their points of consumption in smaller day tanks that feed multiple machines. The chemicals themselves are either sticky and/or corrosive. For this reason, Flowline suggested the use of our ultrasonic sensors that are non-contact, corrosion resistant and completely sealed. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the levels and automatically refills each day tank from bulk storage. Flowline is reliable level measurement. |

Municipal Bleach Day Tank Ultrasonic Level Sensor________________________________________________________________

When Severn Trent of Texas needed reliable level measurement of their customers bleach day tanks, they turned to Flowline. Sodium hypochlorite is a potent disinfectant that’s widely used in municipal drinking water treatment. Somewhat corrosive and highly vaporous, Flowline suggested the use of our pulse radar level sensors in their bleach storage tanks and ultrasonic level sensors in their bleach day tanks. Each ultrasonic sensor provides continuous level data to a local controller, which in turn, displays the day tank inventory, and actuates a fill valve to replenish the tank from bulk storage. Flowline is reliable level measurement. |

Chemical Terminal Storage Radar Level Sensor________________________________________________________________

When a Kansas chemical distributor needed reliable level measurement of their 600,000 gallon terminal storage tanks, they turned to Flowline. At the facility, sodium hydroxide and urea inventories are replenished from railcar deliveries. During the tank filing process, these highly corrosive liquids are agitated, which generates substantial foam and vapor. For this reason, Flowline suggested the use of our pulse radar level sensors that are corrosion resistant and unaffected by such variables. Each pulse radar sensor provides continuous level data to a controller, which in turn, displays the level and actuates a high level audible alarm (mounted on each sensor) to alert the operators when the tank is full. Flowline is reliable level measurement. |

Dairy Chemical Batch Control Guided Wave Level Sensor________________________________________________________________

When a Texas equipment manufacturer needed reliable level measurement of their batch control systems, they turned to Flowline. Their dairy client required an automatic system to blend a critical disinfectant that’s used on cow utters. To makeup each batch, RO water, bleach and germicide are separately dispensed into a PVC tube. The level is measured and used to determine when the correct volume of each ingredient has been input. When done, the batch is transferred into an IBC and the cycle repeats until the tote is full. During blending, the solution foams and level accuracy is critical to batch quality. For this reason, Flowline suggested the use of our guided wave liquid level sensors that are highly accurate and unaffected by foam. The guided wave sensor provides continuous level data to the PLC, which in turn, monitors the tube and controls the batch process. Flowline is reliable level measurement. |