Reservoir Intake Wet Well Ultrasonic Level Sensor_________________________________________________________________

When a Carolina water treatment plant needed reliable level measurement of their reservoir intake wet well, they turned to Flowline. Water is pumped from the nearby river into a 37′ well, that supplies their reservoir. The well is an enclosed, damp and condensing environment that generates substantial water droplets on the underside of the enclosed lid, and any other flat, horizontal surface. During peak condensation, the operators noticed that a typical ultrasonic level sensor would become intermittent, due to condensation buildup on the transducer, that attenuated the acoustic signal and caused instability. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides continuous level data to the SCADA system, which in turn, monitors the well and controls the two pumps. Flowline is reliable level measurement. |

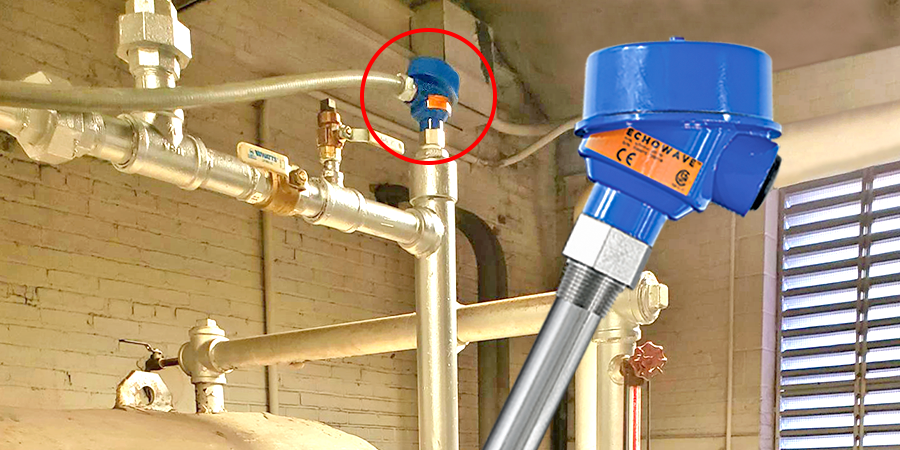

Ferric Chloride Clarifier Tank Radar Level Sensor_________________________________________________________________

When an Idaho water treatment plant needed reliable level measurement of their clarifier tanks, they turned to Flowline. The operators add ferric chloride to wastewater in order to coagulate and separate the solids in their stage one clarifiers. During which, the highly corrosive iron-based chemical releases heat, vapor and foam when agitated. The plant experienced failures with pressure level sensors due to corrosion and clogging, and ultrasonic sensors due to foam and vapor. For this reason, Flowline suggested the use of our non-contact pulse radar level sensors that are unaffected by foam, vapor or agitation. The pulse radar sensor provides continuous level data to the SCADA system, which in turn, monitors the clarifiers and controls the process. Flowline is reliable level measurement. |

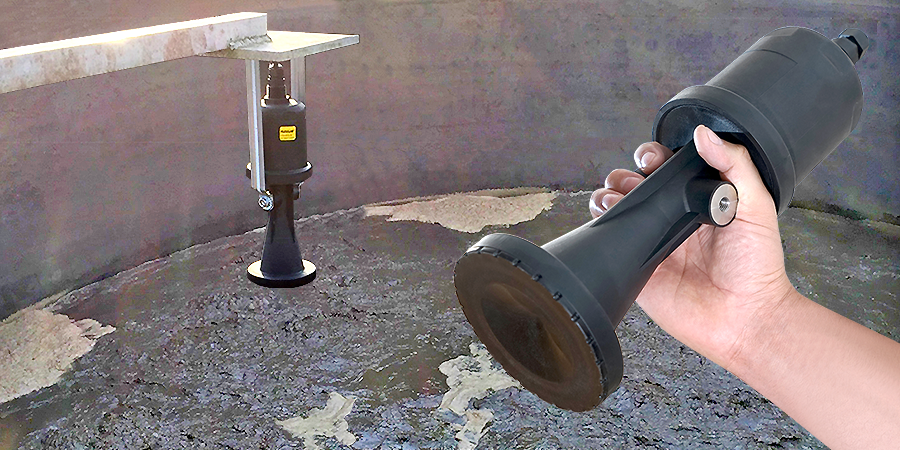

Oil Field Chemical Feed Tank Ultrasonic Level Sensor_________________________________________________________________

When a US energy company needed reliable level measurement of their oil field chemical feed tanks, they turned to Flowline. To improve well production and equipment longevity, anti-scaling chemicals are injected into each well, so as to minimize the salt content of downhole fluids. With hundreds of wells to supply, level measurement is critical, and the operators had problems with pressure sensors due to corrosion, and another brand of ultrasonic sensors due to condensation on the transducer. For this reason, Flowline suggested the use of our non-contact, reflective ultrasonic sensors that work in condensation. The ultrasonic sensors provide continuous level data to the SCADA system, which in turn, monitors the tanks, and alarms for replenishment. Flowline is reliable level measurement. |

Brine Wastewater Storage Tank Radar Level Sensor_________________________________________________________________

When Suez North America needed reliable level measurement of their brine wastewater storage tanks, they turned to Flowline. The environmental company provides industrial and municipal water recycling services to 16k sites, and reliable level measurement is core to their business. At this Northeast location, the operators experienced intermittent performance from ultrasonic level sensors when the temperature dipped below freezing. The tanks are heated, and in extreme cold, the resulting steam, vapor and condensate attenuated their acoustic signal. For this reason, Flowline suggested the use of our pulse radar sensors, that are unaffected by such variables. The pulse radar sensor provides continuous level data to the PLC, which in turn, monitors the tank, and controls the treatment process. Flowline is reliable level measurement. |

Chemical Batch And Storage Tank Ultrasonic Level Sensor_________________________________________________________________

When a North American manufacturer of cleaning and sanitizing chemicals needed reliable level measurement of their batch process and storage tanks, they turned to Flowline. The tanks are of varying size, type and location, and the outdoor tanks are heated to combat freezing temperatures. The operator had problems with a different brand of ultrasonic level sensors, due to ongoing temperature changes, and the resulting condensation build up on the transducers that attenuated their acoustic signal. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide continuous level data to the PLC, which in turn, monitors and refills the baths. Flowline is reliable level measurement. |

Oil Frac Acid Storage Tank Radar Level Sensor_________________________________________________________________

When a North American well service provider needed reliable level measurement of their acid bulk storage tanks, they turned to Flowline. The company distributes hydrochloric acid to many oil and gas well sites from this location. The fracture acidizing process improves well productivity by dissolving material in the productive formation that would otherwise restrict fluid flow. HCL is highly corrosive and vaporous, and the operators had reliability problems with ultrasonic level sensors due to vapor and the resulting signal attenuation. For this reason, Flowline suggested the use of our pulse radar sensors, that are unaffected by vapor, and include a rugged PTFE antenna shield. The pulse radar sensor provides continuous level data to the PLC, which in turn, monitors the tank, and alarms for replenishment. To eliminate the possibility of delivery driver overfill, a high-level safety shut off switch was installed. Flowline is reliable level measurement. |

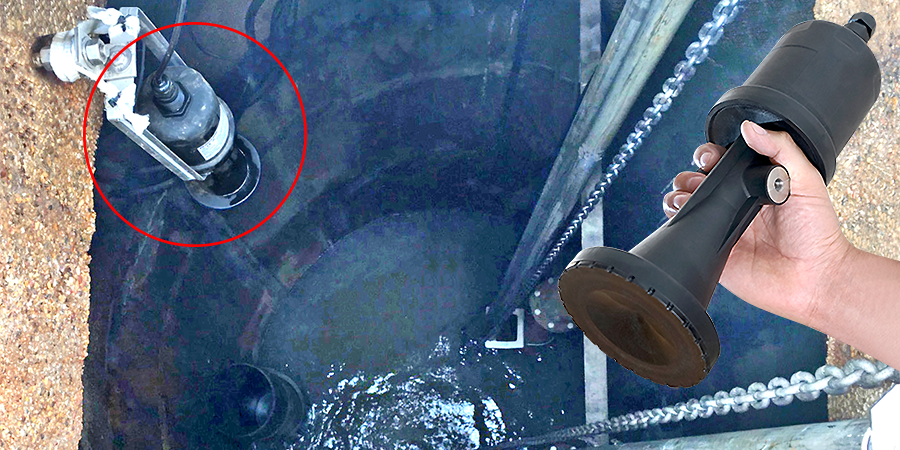

Building Greywater Storage Tank Ultrasonic Level Sensor_________________________________________________________________

When a Boston office building needed reliable level measurement of their greywater bulk storage tank, they turned to Flowline. A LEED compliant design, the building collects, filters and reuses rain, sink, laundry and dishwater to irrigate their landscape. Greywater flows into four lift stations that transfer it to the basement storage tank. There the operators had intermittent problems with a different ultrasonic level sensor due to warm water, and the resulting condensation that attenuated the acoustic signal. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the tank, and controls the irrigation process. Flowline is reliable level measurement. |

Industrial Wastewater Sump Guided Wave Level Sensor_________________________________________________________________

When a Wisconsin cardboard box manufacturer needed reliable level measurement of their sumps, they turned to Flowline. After the cardboard sheets are formed and cut to size, the residual water and fiber material are pumped from each machine into below grade concrete sumps. The waste sumps are very turbulent and the splashing fibers stick to everything. Plant operators couldn’t find a reliable level sensor that didn’t require daily maintenance to remove fiber build-up. For this reason, Flowline suggested the use of our guided wave sensors with a rod antenna that are unaffected by coating. As of this writing, the sensors have been installed for one year and required no maintenance. The guided wave sensors provide reliable level data to the PLC, which in turn, monitors the sump levels and actuates the transfer pumps. Flowline is reliable level measurement. |

Stormwater Pump Lift Station Radar Level Sensor_________________________________________________________________

When a Dallas suburb needed reliable level measurement of their stormwater lift stations, they turned to Flowline. As 2018 was the wettest year on record, the pump stations worked overtime, but the operators remained dry. Because last summer, tired of never ending pressure level sensor failures caused by agitation and coating, they installed Flowline non-contact pulse radar level sensors. Now more than 60″ of rain later, one operator put it this way, “If you ask me, these sensors are like pizza, they work for breakfast, lunch and dinner.” The pulse radar sensors provide continuous level data to the SCADA system, which in turn, monitors the stations and controls the pumps. Flowline is reliable level measurement. |

Boiler Feed Water Tank Guided Wave Level Sensor_________________________________________________________________

When Mansfield University of PA needed reliable level measurement of their boiler feed water tanks, they turned to Flowline. Tired of float level failures caused by scaling or corrosion, and the resulting hot water crisis on campus, facility management decided to upgrade their feed tanks to reliable level measurement. The six tanks contain pre-heated water and recovered steam condensate, with an operating temperature of 140º-180º F. based on the season. Additionally, facility maintenance wished to install the sensors in their external stand pipe manifolds. For the above reasons, Flowline suggested the use of our guided wave level sensors with a coaxial antenna. The stainless steel sensor is unaffected by scaling, has a maximum operating temperature of 302º F., and is easily installed in a metal standpipe. The guided wave sensors provide continuous level data to the controller, which in turn, monitors the tanks and manages the boilers. Flowline is reliable level measurement. |