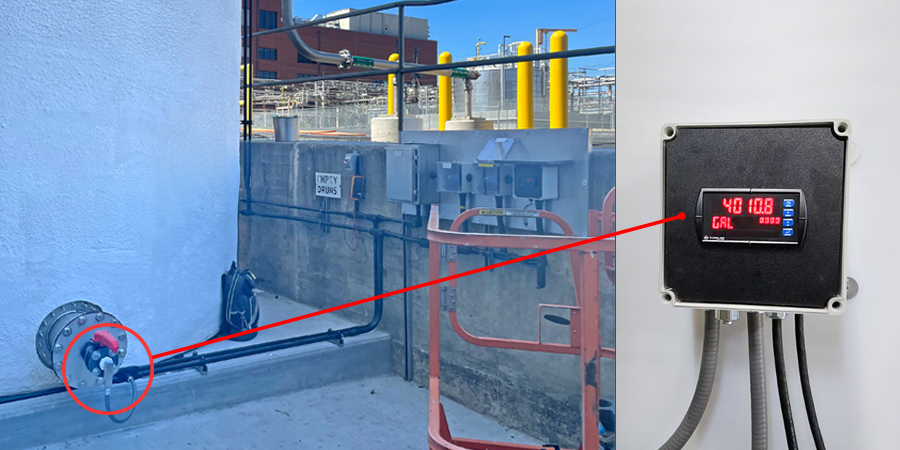

Drinking Water Fluoride Tank Ultrasonic Level Transmitter______________________________________________________ When a Southwest municipality needed reliable level measurement of their fluoride chemical feed tanks, they turned to Flowline. The treatment plant injects a 24% solution of fluorosilicic acid into their distribution system to fluoridate drinking water. A new chemical feed tank was needed, and the plant wanted a total solution including corrosion resistant level measurement, indication and fittings. For this reason, our distributor partner specified our PVDF non-contact ultrasonic level sensor, level indicator, NEMA enclosure and fitting with the tank. One call, single source, reliable tank systems. The ultrasonic sensor provides reliable level data to the level indicator which displays in gallons and alarms for acid replenishment. Flowline is reliable level measurement. |

Chemical Distributor Tank Radar Level Transmitter______________________________________________________ When a Midwest chemical distributor needed reliable level measurement of their solvent and acid storage tanks, they turned to Flowline. The firm receives bulk deliveries at their transloading station where chemicals are pumped from tanker railcars into large storage tanks. There the plant engineer said they needed to replace failing level sensors and stated his requirements. “We want a reliable, non-contact and highly corrosion-resistant sensor that can be applied with acids, caustics or hazardous solvents with a dielectric value ≥ 2.0. Last, if this can be achieved with a single sensor, that’s our preference.” For these reasons, Flowline suggested our intrinsically safe radar sensor that’s flange mounted with a PTFE antenna shield. The radar sensors provide reliable data to the tank indicators and PLC for inventory monitoring. Flowline is reliable level measurement. |

Sulfuric Acid Storage Radar Level Transmitter______________________________________________________ When a Gulf Coast chemical distributor needed reliable level measurement of their acid storage tanks, they turned to Flowline. The firm receives, stores, dilutes and delivers sulfuric acid to clients from their trucking terminal. There they cold store sulfuric in concentrations as high as 99% with an air purge and nitrogen blanket above the liquid. The I&C engineer was dissatisfied with previous ultrasonic level sensors that performed erratically due to vapor and nitrogen signal attenuation. He wanted a reliable, non-contact, corrosion-resistant level sensor that’s not influenced by tank vapor or foaming. For these reasons, Flowline suggested our radar sensor that’s unaffected by such media or process variables, and directly flange mounts with a PTFE antenna shield. The radar sensors provide reliable data to the PLC which monitors the sulfuric tanks and controls the terminal functions. Flowline is reliable level measurement. |

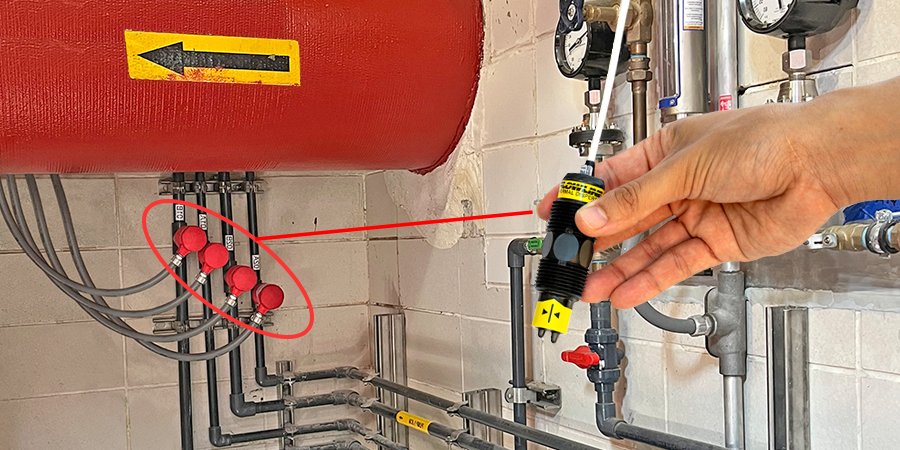

Chemical Pump Protection Thermal Dispersion Flow Switch______________________________________________________ When a Southeast municipality needed reliable chemical process and run-dry pump protection, they turned to Flowline. Diluted chemicals are transferred from storage tanks to day tanks via magnetic drive pumps. But each year, chemical outages de-rail the treatment process or damage costly pumps. To mitigate this, the I&C engineer requested a solid-state corrosion-resistant flow switch that would reliably indicate no or low-flow and empty-pipe conditions. For these reasons, Flowline suggested our thermal dispersion flow switch that’s constructed of PP or PVDF with an adjustable set point, LED flow indicator and selectable NO or NC relay output. The flow switch provides reliable flow detection to the SCADA which controls chemical transfer and water treatment. Flowline is reliable switching. |

Brine Make Up Tank Pressure Level Measurement______________________________________________________ When a Northwest municipality needed reliable level measurement and control of their brine make up tank, they turned to Flowline. The water plant creates brine and then converts it into chlorine via electrolysis. The I&E technician arrived to find that the mechanical contractor had used all available mounting ports on the fiberglass tank, and there was nowhere to install his specified level sensor. He needed ideas as to how he could measure the level without cutting another hole in the tank-top? For this reason, Flowline suggested the use of our external pressure sensor, mounted on the outside of the inspection port with a valve in between for easy removal and inspection. The external pressure sensor provides reliable non-invasive level data to the controller which monitors the tank and alarms when high or low. Flowline is reliable level measurement. |

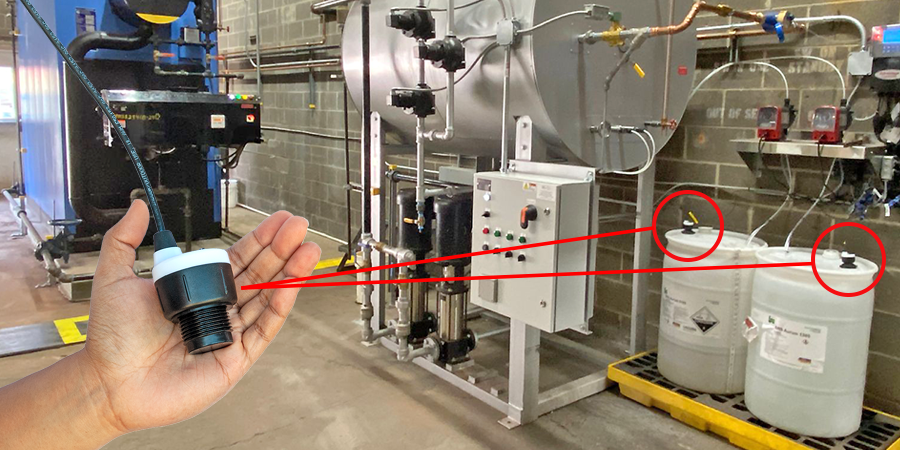

Boiler Chemical Feed Tank Ultrasonic Level Measurement_________________________________________________________________ When a Pennsylvania boiler solutions provider needed reliable level measurement of their clients’ chemical tanks, they turned to Flowline. The firm installs and maintains boiler equipment including the supply of proprietary chemicals to soften the water and inhibit corrosion. This customer was a total refurbishment, and they needed reliable non-contact level measurement of chemical drums and feed tanks. A controller monitors the levels and sends email notifications to those responsible for replenishing their chemicals. For these reasons, Flowline suggested our DL10 ultrasonic level sensor that’s reliable, constructed of PVDF and designed for small tank applications. The ultrasonic sensors provide reliable level data to the controller which monitors the feed tanks and alarms for replacement or refill. Flowline is reliable level measurement. |

School Heating Oil Bulk Tank Ultrasonic Level Measurement______________________________________________________ When a Nova Scotia elementary school needed reliable level measurement of their heating oil tanks, they turned to Flowline. With an average winter temperature of -2º C., school classrooms are heated via forced air furnaces. Each burner is fueled by a 500-gallon heating oil tank that’s truck refilled on a regular basis. The previous float level switches would often stick and required ongoing maintenance. This led to oil outages, cold students and angry parents. A system integrator was hired to replace the switches with reliable non-contact measurement, and push the tank data to a cloud for supplier and staff visibility. For these reasons, Flowline suggested our ultrasonic level sensors that are ideal for heating or diesel oil applications, and we’re awarded Processing’s Breakthrough Product of the Year. The ultrasonic sensors provide reliable level data to the controllers, which post the tank inventories and send email notifications for replenishment. Flowline is reliable level measurement. |

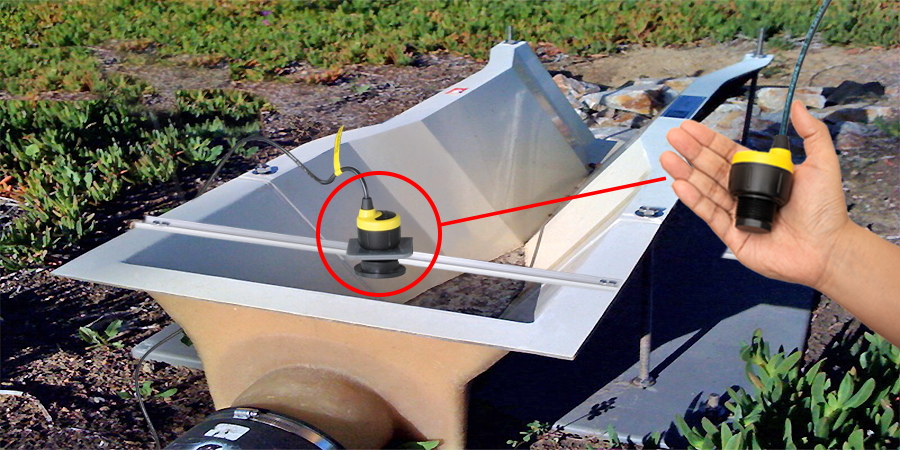

Stormwater Run-Off Flume Flow Ultrasonic Level Measurement______________________________________________________ When a California municipality needed reliable flow measurement of their stormwater run-off flumes, they turned to Flowline. To retain water that would otherwise go to the ocean, the state’s increasingly diverting highway stormwater into nearby settling ponds to recharge their aquifers. There the I&C engineer had setup several flumes to measure the effectiveness of these programs by comparing the volume of stormwater discharged into the ponds versus their impact on increasing the level height of the aquifers. To do so, he needed a reliable, non-contact level sensor with a small dead band, minimal installation footprint and no display. For these reasons, Flowline suggested our EchoPod ultrasonic level sensor that’s small, easy to install, and features an industry leading 2″ dead band. The ultrasonic sensors provide reliable level data to the SCADA, which translates this to gallons for analysis. Flowline is reliable level measurement. |

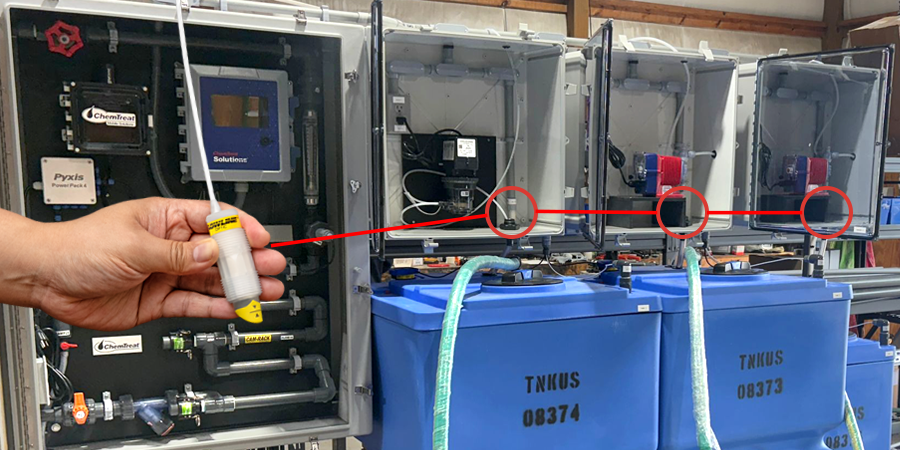

Chemical Pump Enclosure Leak Detection Switch______________________________________________________ When a Southern equipment company needed reliable leak detection of their pump enclosures, they turned to Flowline. The firm engineers and assembles chemical feed skids for industrial water treatment customers, and safety and reliability are absolute requirements. The lead engineer wanted a solid-state, corrosion-resistant switch to reliably detect a leak in each enclosure. He also enquired whether fail-safety was available in a switch. For these reasons, Flowline suggested our optic leak switch that features a submersible PP sensor body and cable with a 1A relay output. Additionally, optic is the only switch technology that inherently fails wet, and thus provides fail-safety. The switch is widely used in containment sumps, dual wall tanks and piping systems. The optic switch provides reliable leak detection and contact closure signaling to the controller for maintenance. Flowline is reliable leak detection. |

Rice and Crawfish Farm Water Ultrasonic Level Measurement______________________________________________________ When a Louisiana farmer needed reliable water level monitoring of their rice fields, they turned to Flowline. After planting, the water level is steadily increased throughout the growth cycle. When the crop provides enough sunshade, the farmer adds crawfish larva which grows, deposits waste and fertilizes the crop. When the rice is harvested, the field is drained, the crawfish burrow into the soil, hibernate, and are harvested the following year. The farm’s system integrator wanted a reliable, non-contact level sensor with a voltage output that’s optimized for short range and compatible with standpipes to isolate the measurement from weather. For these reasons, Flowline suggested our EchoPod level sensor with a selectable voltage or frequency signal output. The ultrasonic sensor provides reliable level data to the solar-battery-powered RTU, which pushes the data to the farmers cloud and phone. Flowline is reliable level measurement. |