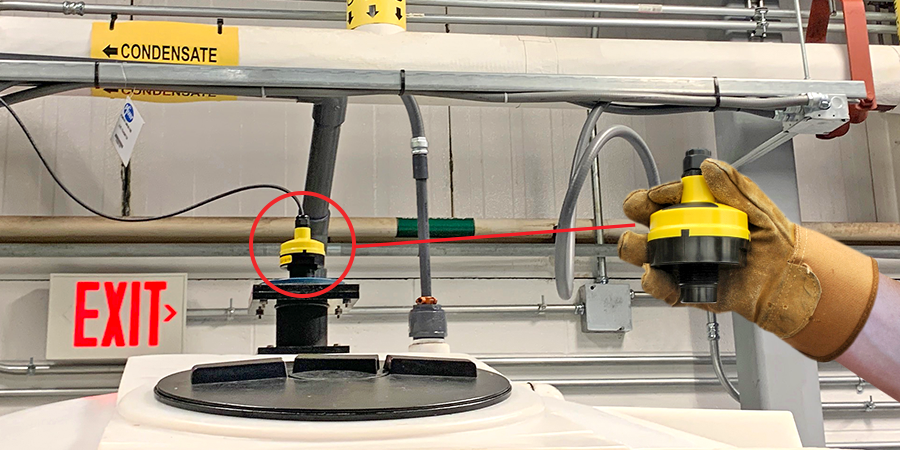

Rinse Water Neutralization Ultrasonic Level Measurement_________________________________________________________________ When a Wisconsin metal auto parts manufacturer needed reliable level measurement of their rinse water neutralization tank, they turned to Flowline. Parts are pressure washed with solvent to remove oil, grease and contaminants. Then they’re rinsed in a heated water tank with 2% hydrochloric acid. Each day, the rinse tank is emptied, filtered and pumped to a neutralization tank for reclamation. There the operator complained that a different ultrasonic level sensor brand became unstable shortly after transfer of the heated water due to condensation on the transducer. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides reliable level data to the PLC which controls the process. Flowline is reliable level measurement. |

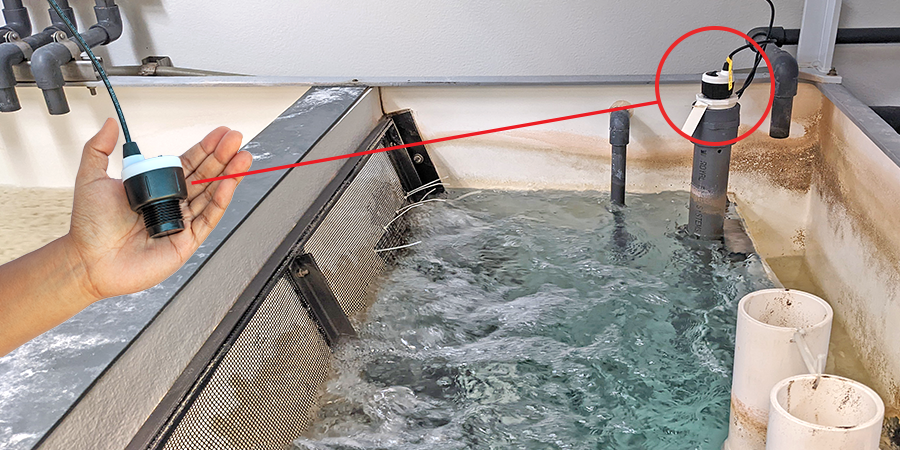

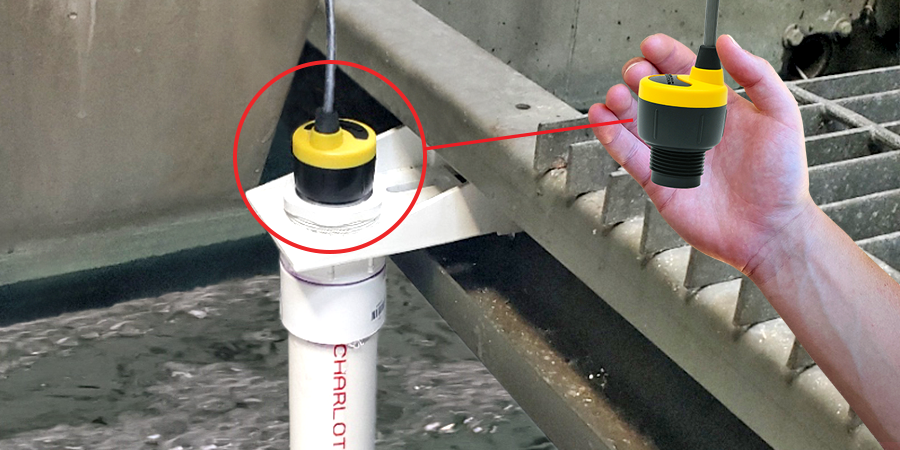

Aquarium Biomedia Tank Ultrasonic Level Measurement_________________________________________________________________ When a Southeast aquarium needed reliable level measurement of their water treatment tanks, they turned to Flowline. Exhibit water is continuously pumped through filtration tanks that use floating bacteria laced media to consume the biological solids. It’s a simple system. Water enters the tank on the left, circulates with biomedia, and then passes through a screen before exiting on the right. The life science director said that the past float level sensors required frequent removal and cleaning, and was a nuisance to maintain. For this reason, Flowline suggested our maintenance free non-contact ultrasonic sensor installed in a stand-pipe to dampen any agitation. The ultrasonic sensor provides reliable level data to the PLC which controls the process. Flowline is reliable level measurement. |

Truck Stop DEF Storage Tank Ultrasonic Level Measurement______________________________________________________ When a Midwest truck stop needed reliable level measurement of their DEF fluid storage tank, they turned to Flowline. In each fueling bay, drivers fast dispense DEF into their rigs. The DEF dispensers are fed by a single storage tank that’s refilled every 2-3 weeks by their chemical supplier. The operator stated that past pressure level sensors had failed due to corrosion, and the replacement ultrasonic sensor became unreliable during the hot humid months of summer due to condensation on the transducer. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation.The intrinsically safe ultrasonic sensor provides reliable level data to the PLC which alarms for resupply. Flowline is reliable level measurement. |

PCB Etch Neutralization Tank Ultrasonic Level Measurement______________________________________________________ When a Canadian manufacturer of printed circuit boards needed reliable level measurement of their neutralization tanks, they turned to Flowline. The firm uses several etchants like copper chloride to dissolve the unwanted trace material from PCB’s. Each process line generates a corrosive waste stream that flows into small neutralization tanks. There the operator said that past pressure level sensors had failed due to corrosion, and ultrasonic sensors were erratic due to limited measurement space with pipes, sensors and inflow streams. For these reasons, Flowline suggested our ultrasonic sensors installed in a standpipe to separate the measurement signal from the various obstacles. The ultrasonic sensors provide reliable level data to the PLC which controls the process. Flowline is reliable level measurement. |

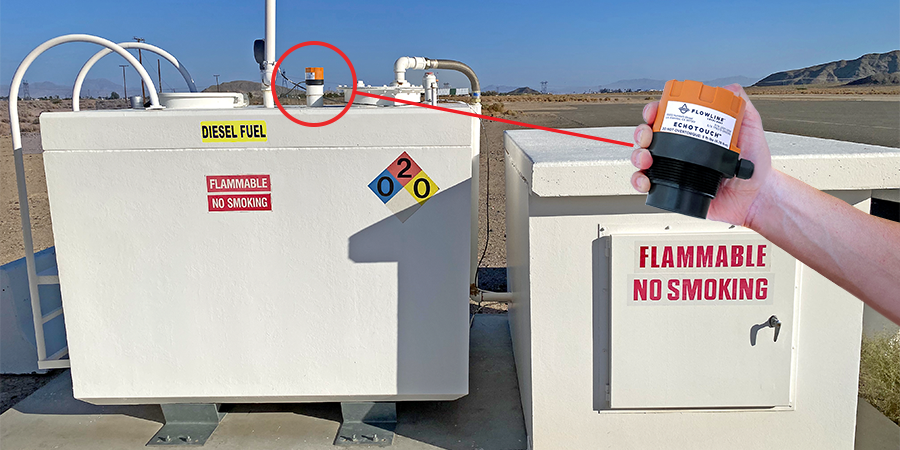

Fire Helicopter Fuel Station Ultrasonic Level Measurement______________________________________________________ When an Arizona county fire authority needed reliable level measurement of their remote diesel tank refueling stations, they turned to Flowline. As heavy equipment fire trucks and bull dozers are deployed deeper off grid, they must be refueled using helicopters. To do so, the county maintains remote fuel stations with helicopter landing pads and lift hoist bladder tanks through which they can fill, transport and deliver diesel from the air. There the county wanted a reliable, intrinsically safe, non-contact level sensor that would interface with their SCADA for remote inventory monitoring. For this reason, Flowline suggested our ultrasonic level sensors that are ideal for diesel fuel. The ultrasonic sensors provide reliable level data to the SCADA which alarms for refill. Flowline is reliable level measurement. |

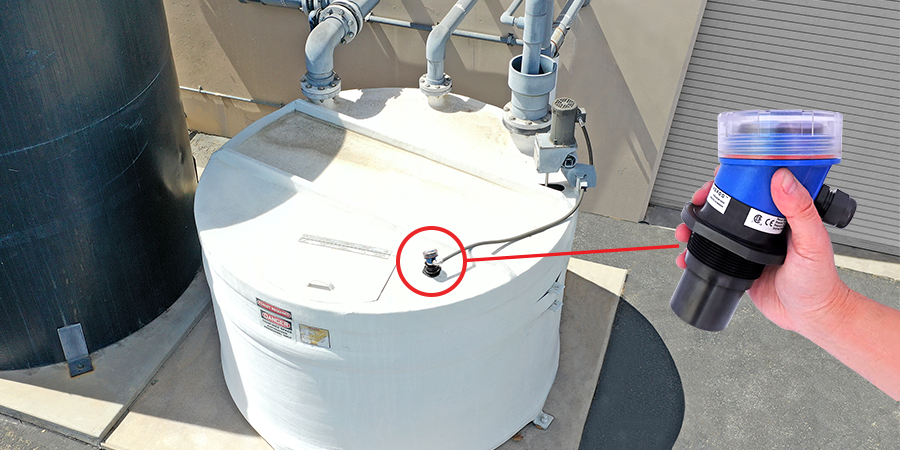

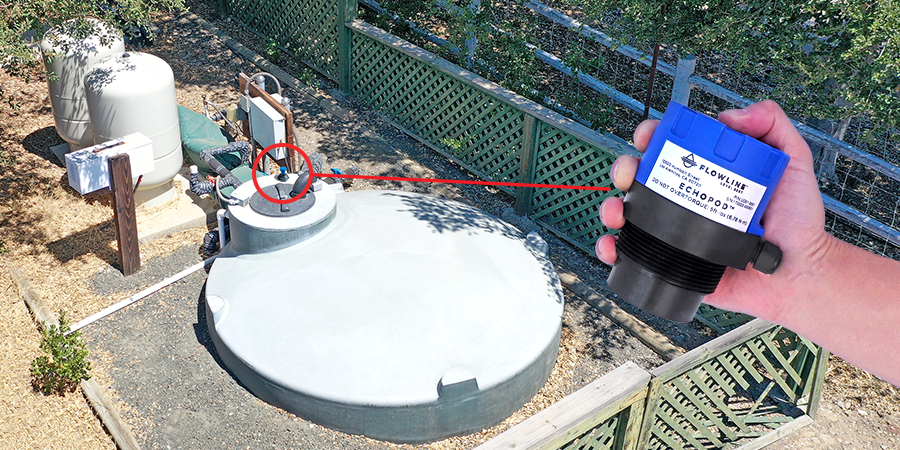

Vineyard Well Storage Tank Ultrasonic Level Measurement______________________________________________________ When a California winery needed reliable level measurement of their well storage tanks, they turned to Flowline. With ground water declining and drill permits on hold, farmers must maximize the efficiency of existing wells. As many wells are tied into the same aquifer, they impact one another and efficiency requires a networked approach with level measurement versus switches. By measuring tank fill rate, the SCADA can determine well health to best manage pump speeds, recharge times and water distribution across the network. Their system integrator required maintenance free level sensors designed for outdoor use. For this reason, Flowline suggested our non-contact ultrasonic sensors. The ultrasonic sensors provide reliable level data to the SCADA which controls the wells. Flowline is reliable level measurement. |

Bleach Chemical Feed Tank Ultrasonic Level Measurement______________________________________________________ When an Alabama municipality needed reliable level measurement of their sewer pump station chemical feed tanks, they turned to Flowline. To improve treatment plant efficiency, sewer water disinfection begins in their lift stations. There the plant steadily injects diluted streams of sodium hypochlorite. The operator explained that previous ultrasonic level sensors became unreliable during the summer months as condensation increased, which resulted in nuisance alarms and frustration. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the SCADA system which alarms for chemical refill. Flowline is reliable level measurement. |

Plastic Pellet Storage Silo Radar Level Measurement______________________________________________________ When a New York building materials manufacturer needed reliable level measurement of their plastic pellet storage silos, they turned to Flowline. The company produces non-metallic window, door and roofing products for residential builders, and PVC plastic is a core input. The operator said that their previous yo-yo-type mechanical level sensors were inaccurate, which resulted in pellet shortages and production downtime. They needed reliable level measurement with indication converted from height to pounds and high and low silo alarms. For these reasons, Flowline suggested our non-contact radar sensors with level controllers. The radar sensors provide reliable level data to the controllers for silo inventory and alarms. Flowline is reliable level measurement. |

Condensate Recovery Tank Ultrasonic Level Measurement______________________________________________________ When an East Coast pharmaceutical company needed reliable level measurement of their HVAC condensate recovery tank, they turned to Flowline. Temperature control is critical to their products and the warehouse is maintained near 2º Celsius. The HVAC system is designed around fail-safety with redundant power and water sources. Condensate is collected and transferred to a basement storage tank, prior to treatment and recirculation. There the plant engineer required a reliable non-contact level sensor and redundant high-level alarm that would work with foam and particulate in the condensate. For this reason, Flowline suggested our ultrasonic sensor installed in a standpipe to separate foam from the point of measurement, and a vibration level switch, suspended below the tank top. The ultrasonic sensor provides reliable level data to the PLC which controls the process. Flowline is reliable level measurement. |

Cooling Tower Water Sump Reliable Ultrasonic Level Measurement______________________________________________________ When a Midwest corrugated paper manufacturer needed reliable level measurement of their cooling tower water sumps, they turned to Flowline. The firm produces custom boxes, inserts and point of sale display packaging for beverage companies, and their processes generate substantial heat. Machine temperatures are regulated with cooling water supplied by two towers. There the facility operator experienced frequent float level switch failures due to corrosion, scaling or chatter, and replacement forced costly downtime. For these reasons, Flowline suggested our non-contact ultrasonic level sensor with four relays installed in a standpipe. The relay set points are configured to the previous float levels for seamless integration. The ultrasonic sensors provide reliable level switching to the PLC which controls the cooling process. Flowline is reliable level measurement. |