Food Truck Sanitization Tank Guided Wave Radar Level Measurement______________________________________________________ When an Oregon sugar distributor needed reliable level measurement of their truck sanitization batch mix tank, they turned to Flowline. The firm delivers granular bulk sugar to food manufacturers. At the end of each day, their empty tanker trucks pull into a wash station for container cleaning. Spray heads are lowered inside, and the containers are washed with chemicals and rinsed with hot water. There a make-up tank is separated into two compartments, one side for chemical and the other for hot water. The operator required reliable level measurement, indication and alarming of both compartments. For this reason, Flowline suggested our guided wave sensors that are ideal for heated applications and our level controllers for local display with alarms. The guided wave sensors provide reliable level data to the controllers for indication and alarms. Flowline is reliable level measurement. |

Concrete Chemical Bulk Tank Ultrasonic Level Measurement______________________________________________________ When a Pennsylvania concrete block manufacturer needed reliable level measurement of their storage tanks, they turned to Flowline. The firm produces concrete blocks for home improvement retailers and commercial builders. In which, they inject five chemicals to improve wet concrete pourability, and increase the strength of cured blocks. The operator said the mixture ratio is constant. As such, he only needed to measure their highest volume chemical to know when it’s time to reorder all. Additionally, he wanted a maintenance free level sensor with easy configuration. For these reasons, Flowline suggested our non-contact ultrasonic sensor with an integral push button display. The ultrasonic sensor provides reliable level data to the PLC that alarms for replenishment. Flowline is reliable level measurement. |

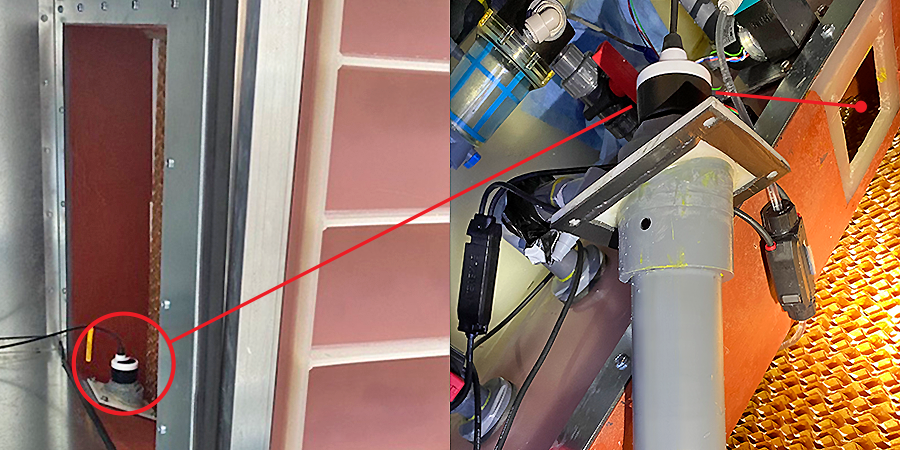

Cooling Tower Water Sump Ultrasonic Level Measurement________________________________________________________________ When a Midwest HVAC contractor needed reliable level measurement of their clients cooling tower sumps, they turned to Flowline. After numerous level failures, a hospital contracted with them to replace every float level sensor with something robust. Their engineer said that float failures are caused by scaling, corrosion and sump turbulence. In changing, he wanted level measurement versus switching, because it gave them set point flexibility in the PLC. For these reasons, Flowline suggested our non-contact and corrosion resistant ultrasonic sensors installed in a standpipe which dampens turbulence for a clean signal output. The ultrasonic sensors provide reliable level data to the PLC that actuates the fill valve. Flowline is reliable level measurement. |

Lumber Mill Machinery Sump Ultrasonic Level Measurement_________________________________________________________________ When a Florida lumber mill needed reliable level measurement of their machine sumps, they turned to Flowline. During and after significant rain or tidal events, the low-lying land can quickly flood, putting staff and machinery in harm’s way. Sump pumps keep the operation safe most of the time, but when the infill rate exceeds pump capacity, sump levels rise and inevitably flood the property. The operator said that during such events, minutes count and he wanted to detect the trend and alarm early, versus waiting for a slower rise to reach a high-level state. For this reason, Flowline suggested our ultrasonic level sensors installed over each sump. The ultrasonic sensors provide reliable level data to the PLC that monitors the sumps, alarms on a rising trend and shuts down the machines prior to flooding. Flowline is reliable level measurement. |

Pork Plant Disinfection Tank Radar Level Measurement_________________________________________________________________ When an Arkansas pork processor needed reliable level measurement of their chlorine storage tanks, they turned to Flowline. Every 72 hours, the plant stops processing to clean and disinfect their work surfaces and equipment. In so, peracetic acid and hydrogen peroxide are sprayed on and brushed in cleaning, and then chlorine dioxide is sprayed on for disinfection and rinsed with a pressure washer. The operator said they’ve had level problems in the chlorine tank with ultrasonic sensors due to vapor and pressure sensors due corrosion, and both had led to chemical shortages and costly downtime. For these reasons, Flowline suggested our radar sensors that are unaffected by chlorine vapor with a PFA antenna for strong corrosion resistance. The radar sensors provide reliable level data to the PLC that monitors the tanks and alarms for reorder. Flowline is reliable level measurement. |

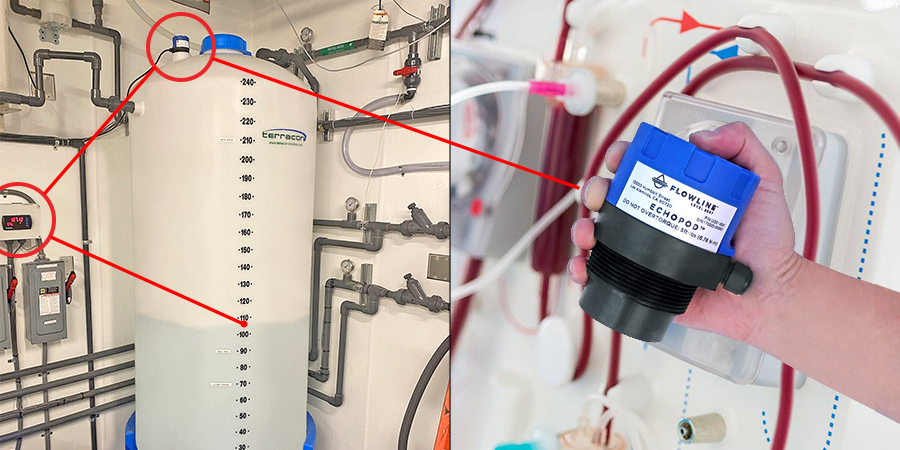

Dialysis RO Water Day Tank Ultrasonic Level Measurement_________________________________________________________________ When a Mississippi hospital needed reliable level measurement of their dialysis reverse osmosis day tank, they turned to Flowline. Patients receive an average of 150L of solution during each treatment, and are hence vulnerable to mineral and bacterial contaminants. Therefore, the dialysis machines are fed ultrapure water from a reverse osmosis system and 250-gallon day tank. The entire system is level driven and the engineer required non-contact level measurement, indication and relay control for valve and alarm actuation. For these reasons, Flowline suggested an ultrasonic sensor and level controller mounted in a NEMA enclosure. The ultrasonic sensor provides reliable level data to the level controller which indicates in gallons, controls tank refill and alarms when low. Flowline is reliable level measurement. |

Plating Wastewater Bulk Tank Ultrasonic Level Measurement______________________________________________________ When an Ohio metal finishing firm needed reliable level measurement of their wastewater tanks, they turned to Flowline. The company etches, anodizes, plates and polishes parts for aerospace, military and marine customers. Their liquids range from solvents to acids and their wastewater streams are corrosive, dirty, foaming and potentially explosive. The operator required a non-contact level sensor that would operate reliably under these conditions with a level indicator and repeater for the PLC. For these reasons, Flowline suggested our intrinsically safe ultrasonic sensor installed in a standpipe and connected through an IS barrier to our indicator with repeater and windowed NEMA enclosure. The ultrasonic sensor provides reliable level data to the indicator which displays level height in feet, and repeats the signal to the PLC. Flowline is reliable level measurement. |

Fire Sprinkler Supply Tank Ultrasonic Level Measurement______________________________________________________ When a California building automation system integrator needed reliable level measurement of their fire sprinkler water supply tanks, they turned to Flowline. In high rises or large buildings, state fire codes typically require secondary water tank systems, capable of supplying 30 minutes of fire suppression if municipal water service is disrupted. In which, the system must have level equipment to detect and automatically refill the tanks when low. The engineer required a reliable non-contact level sensor that’s unaffected by condensation for use with their building automation system. The ultrasonic sensors provide reliable level data to the SCADA which monitors the tanks on each floor and controls their refill. Flowline is reliable level measurement. |

Scrubber Wastewater Tank Ultrasonic Level Measurement______________________________________________________ When a Gulf chemical distributor needed reliable level measurement of their scrubber recovery tank, they turned to Flowline. The company bulk stores and distributes hydrochloric acid, a corrosive and vaporous chemical that requires scrubbing prior to vapor release to the atmosphere. Scrubber waste is periodically transferred to a holding tank prior to wastewater treatment. There the operator required a corrosion resistant, non-contact level sensor with an onboard display and conduit termination. For these reasons, Flowline suggested our ultrasonic level sensor with a PVDF transducer and NEMA 4X polycarbonate enclosure. The ultrasonic sensor provides reliable level data to the PLC which monitors the tank and transfers its contents to treatment. Flowline is reliable level measurement. |

Wastewater Open Channel Radar Flow Measurement______________________________________________________ When a Northwest sugar processing plant needed reliable open channel flow measurement of their industrial waste stream, they turned to Flowline. The company measures, totalizes and reports the wastewater they release each month to the water plant for environmental compliance and treatment billing. The measurement is taken in a parshall flume located in the sewer entrance. Their waste discharge is hot, condensing and often foaming. The operator complained that the prior ultrasonic sensor was intermittent in this application, and they needed reliable measurement. For these reasons, Flowline suggested our radar sensors that are unaffected by media or environmental changes. The radar sensor provides reliable level data to the indicator which repeats the signal to the PLC for flow conversion and data logging. Flowline is reliable flow measurement. |