Water Irrigation Canal Radar Level Measurement______________________________________________________ When a Michigan farm company needed reliable level measurement of their irrigation canals, they turned to Flowline. Located adjacent to a wetland, a series of canals feed the nearby farms with fresh water during the growing season. Each canal has a weir, motorized gate and level sensor that are networked via wireless SCADA. The gates are adjusted weekly based on weather and water demand. The owner said that previous ultrasonic level sensors became erratic during their summer rain or high wind events, and they needed reliable level measurement. For this reason, Flowline suggested our radar sensors that are unaffected by weather, and ideal for canal applications. The radar sensors provide reliable level data to the SCADA which monitors the canals and controls the gates. Flowline is reliable level measurement. |

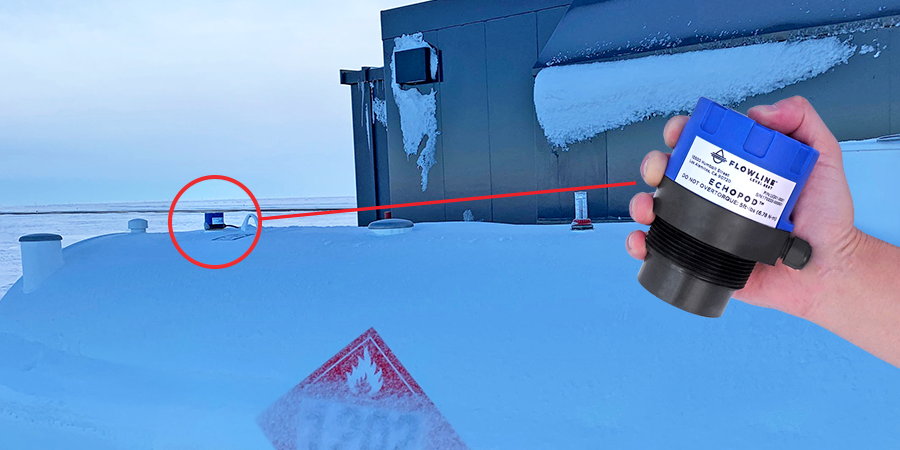

Oil Field Diesel Storage Tank Level Measurement______________________________________________________ When a Canadian oil drilling contractor needed reliable level measurement of their diesel storage tanks, they turned to Flowline. The firm maintains remote fuel stations to support their vehicles, rigs and power generators in the field. The tanks are monitored, and the inventory data is uploaded to their fuel supplier for monthly replenishment. The operator said that during winter, condensation in the tank turns to ice, which caused previous float level sensors to stick high, and falsely indicate they had lots of diesel. He wanted a reliable, solid-state level sensor that’s unaffected by condensation and that performs to -40º C. For this reason, Flowline suggested our reflective ultrasonic sensors. The ultrasonic sensors provide reliable level data to the SCADA which monitors the inventories and alarms for replenishment. Flowline is reliable level measurement. |

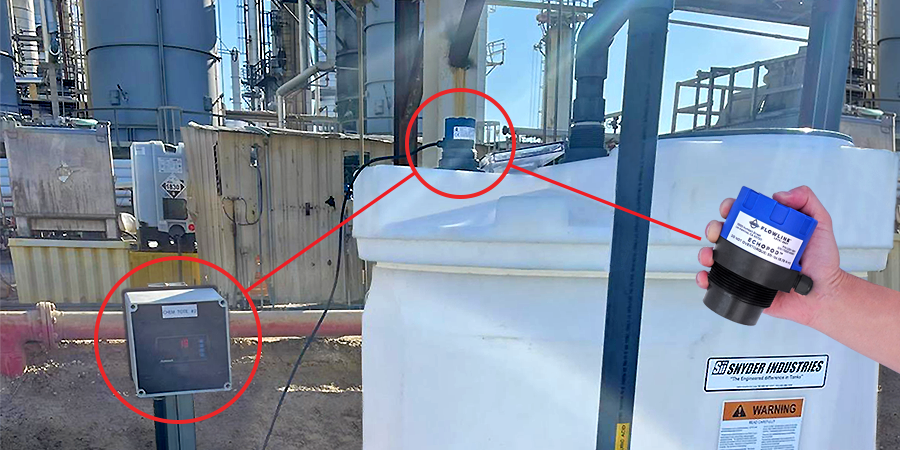

Refinery Caustic Soda Tank Ultrasonic Level Measurement______________________________________________________ When a California refinery needed reliable level measurement of their sodium hydroxide mini-bulk tanks, they turned to Flowline. Caustic is used to remove sulfur impurities from oil and mitigate the corrosive effects of hydrochloric acid, a by-product of the refining process, on plant equipment. To do so, NaOH is injected through metering pumps at eight chemical feed stations. There the operator required reliable non-contact level measurement, NEMA 4X displays and pump control to auto-refill each tank. For these reasons, Flowline suggested our ultrasonic level sensors, coupled with a level controller, mounted in a windowed enclosure. The ultrasonic sensors provide reliable level data to the controllers which display the gallonage and control the transfer pumps. Flowline is reliable level measurement. |

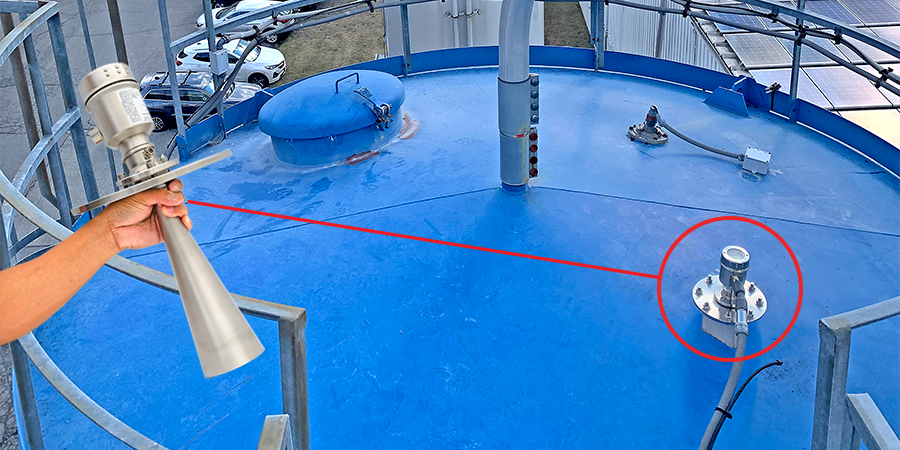

Coastal Canal Flood Control Radar Level Measurement______________________________________________________ When a Florida community needed reliable level measurement of their residential water canals, they turned to Flowline. The canals provide boat access to coastal waters, storm drainage and flood control during significant weather. At each road culvert, a gate controls the open water flow or transfer from one side of the canal to the other, to balance the tidal and storm inflows with canal capacity. There the system integrator required two level sensors, one to measure on each side of the vaulted gate, and both must perform in sun, rain, high wind and storm turbulence. For these reasons, Flowline suggested our radar sensors that are unaffected by the environment and designed for outdoor use. The radar sensors provide reliable level data to the SCADA which monitors the levels and controls the gates. Flowline is reliable level measurement. |

Reliable Plastic Pellet Storage Silo Radar Level Measurement______________________________________________________ When an East Coast food packaging manufacturer needed reliable level measurement of their plastic pellet silos, they turned to Flowline. The company produces plastic to-go-containers for restaurants, universities and convenience stores. These are typically opaque containers with translucent lids constructed of molded polypropylene. Three tall silos provide a steady supply of pellets to their molding machines. There the operator said that previous ultrasonic level sensors were erratic, had caused several outages, and they needed reliable measurement. For this reason, Flowline suggested our radar sensors that are ideal for plastic pellets. The radar sensors provide reliable level data to their automation software, which monitors the silos and alarms for replenishment. Flowline is reliable level measurement. |

Water Retention Pond Vault Ultrasonic Level Measurement______________________________________________________ When a California municipality needed reliable level measurement of their water retention ponds, they turned to Flowline. The community receives 16″ of rain per year, yet most stormwater passes from concrete gutter to drainage with little ground water replenishment. To mitigate this, the city has installed cascading ponds at creek sites to capture, screen and pump water from the lower ponds back to the top ponds for further recharging. There the operator said that silt and debris in the pump vault often clogged past pressure level transmitters, and they wanted reliable level measurement. For this reason, Flowline suggested our ultrasonic level sensor installed in a standpipe with a screen on the pipe end to eliminate debris from entering. The ultrasonic sensors provide reliable level data to their SCADA, which monitors the lower ponds and controls the pumps. Flowline is reliable level measurement. |

Water Remote Lake Water Level Monitoring______________________________________________________ We managed to install Radar Liquid Level Sensor Transmitter (LR30) for our customer for their remote lake water level monitoring. This non-contact liquid level sensor provides continuous level measurement up to 30m with a 4-20 mA signal output and is configured via its remote push button display module. The sensor was placed at Jurong Lake Gardens. |

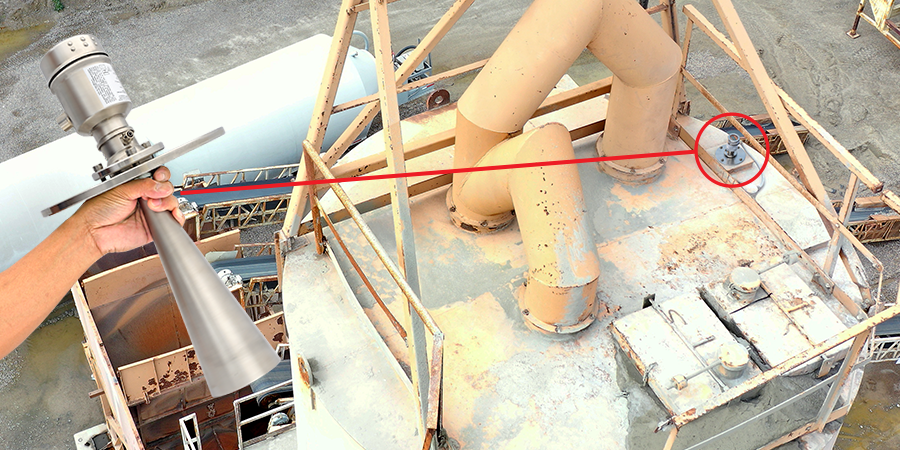

Concrete Batch Mixing Silo Radar Level Measurement______________________________________________________ When an Idaho cement company needed reliable level measurement of their concrete batch mix silo, they turned to Flowline. When the firm gets a large job that’s outside their service radius, they setup a portable batch plant near the customer. At which, cement, gravel, sand and water are fed into a silo, mixed and pumped into trucks for delivery. There the operator needed a reliable, non-contact level sensor to monitor the batch make up, mixing and dispensing process. For this reason, Flowline suggested our radar sensors that are ideal for aggregate and slurry level measurement. The radar sensor provides reliable level data to the level controller for indication and alarms. Flowline is reliable level measurement. |

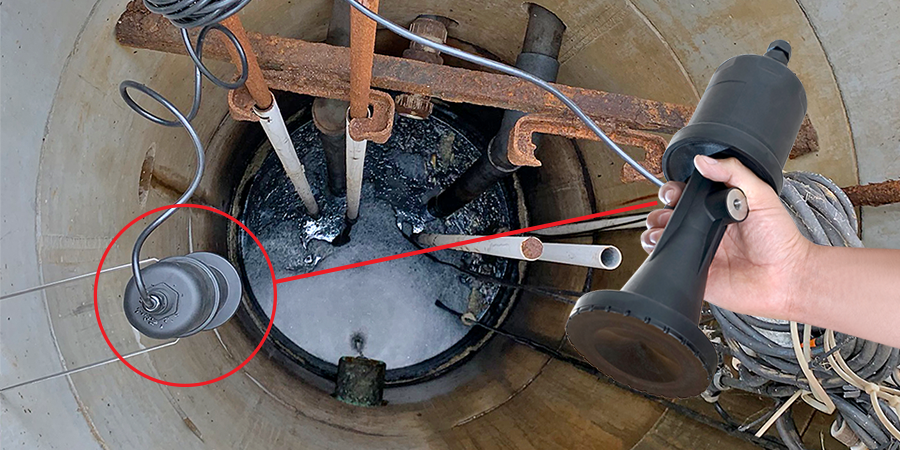

Foaming Sewer Lift Station Radar Level Measurement______________________________________________________ When the United States Air Force needed reliable level measurement of a foaming sewer lift station, they turned to Flowline. Located next to the chow hall, the pump station receives and transfers three square meals of kitchen and bath effluent per day including food, feces, grease, oil and detergents. But the problem here was foam that attenuated the past ultrasonic sensor signal, which made it erratic and caused several overflows. The maintenance officer required a reliable non-contact level sensor that is not impacted by foam. He also needed a level display for placement in their panel for quick reference. For these reasons, Flowline suggested our downhole radar sensors that are unaffected by foam, turbulence or condensation. The radar sensor provides reliable level data to the PLC and local display for indication. Flowline is reliable level measurement. |

Remediation Storage Tank Ultrasonic Level Measurement_________________________________________________________________ When an Illinois groundwater remediation firm needed reliable level measurement of their bulk tanks, they turned to Flowline. Their customer, a commercial real estate developer purchased land that’s adjacent to a former heavy equipment yard with diesel fuel contamination. Shallow wells were dug, and the contractor pumped the top oily layer of groundwater into two manifolded storage tanks for offsite treatment and disposal via tanker trucks. There the operator needed a reliable, non-contact level sensor that would measure the tanks fill and actuate a high-level alarm for his crew to shut off the pump. For these reasons, Flowline suggested our ultrasonic sensors with embedded relays and configurable logic via WebCal software. The ultrasonic sensor provides reliable level measurement and alarm actuation. Flowline is reliable level measurement. |