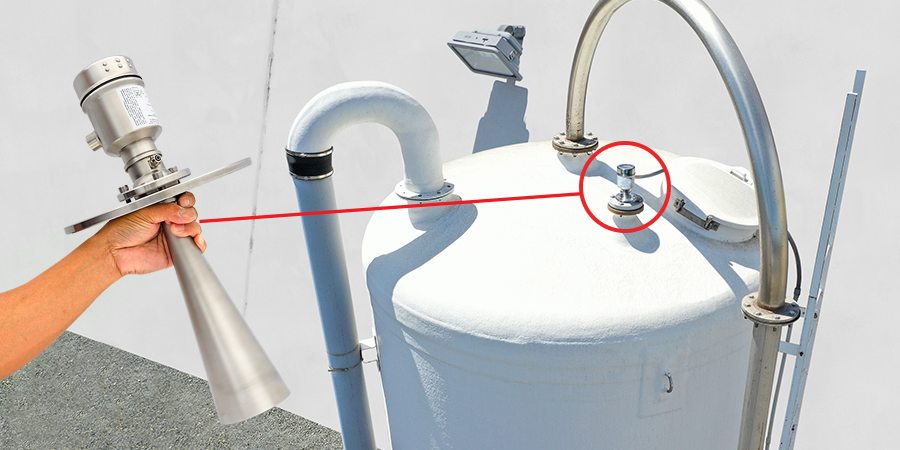

Drinking Water Storage Tank Radar Level Measurement________________________________________________________________ When an Arizona water treatment plant needed reliable level measurement of their massive bulk storage tanks, they turned to Flowline. Baking in the desert sun, the tall metal tanks hold up to 50k gallons each and serve as batch tanks through which drinking water is redistributed to several communities. The flow rate through the plant is regulated by demand and the availability of water in each tank to meet it. These level applications are critical and the operator required the highest measurement reliability. For this reason, Flowline suggested our radar sensors that are unaffected by media, process or environmental factors. The radar sensors provide reliable level data to the SCADA, which monitors the tanks and controls the treatment and distribution process. Flowline is reliable level measurement. |

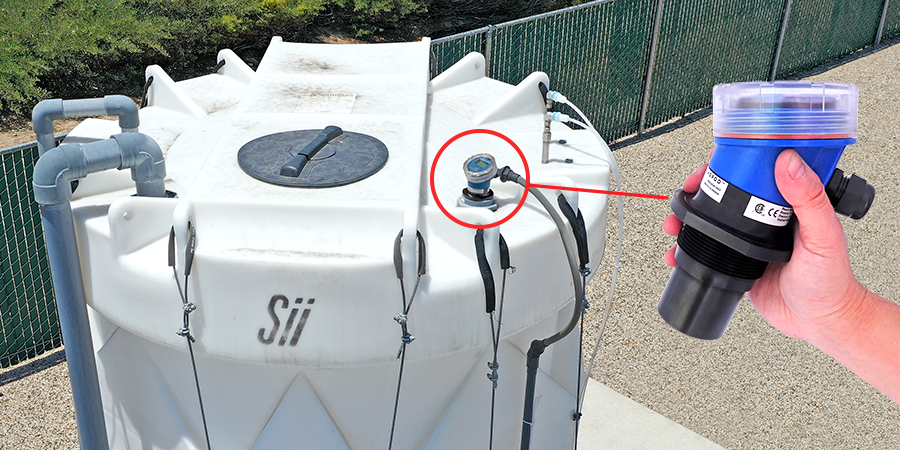

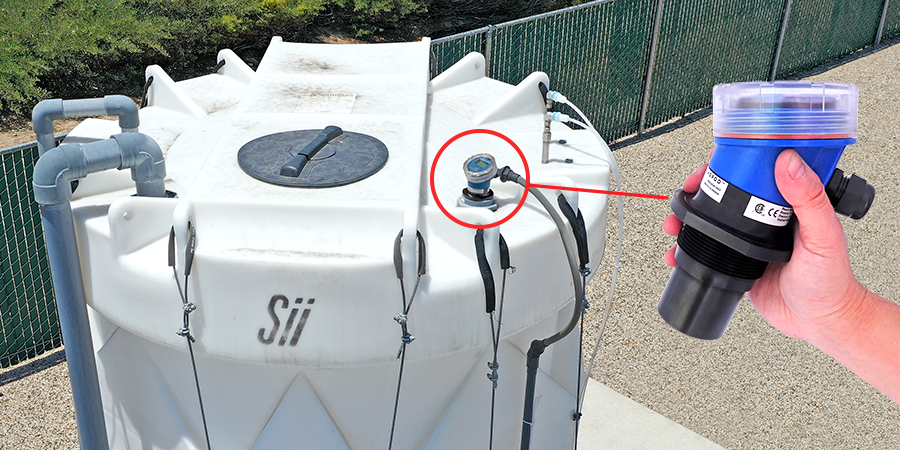

Fertigation Chemical Tank Ultrasonic Level Measurement______________________________________________________ When a California strawberry farm needed reliable level measurement of their fertilizer chemical feed tanks, they turned to Flowline. To maximize plant growth and fruit yields, the farm injects nitrogen, potassium and phosphorous based fertilizers into their irrigation pump station. The fields are remote, and the workers infrequently see the tanks, which led to chemical outages that effected plant growth. They contracted with a system integrator to install a cell modem that would text daily tank inventories to the manager. The integrator requested a level sensor that would reliably work with sticky and corrosive fertilizers. For this reason, Flowline suggested our non-contact ultrasonic sensors. The ultrasonic sensors provide reliable level data to the modem, which transmits a daily inventory packet. Flowline is reliable level measurement. |

Resin Bulk Transfer Station Radar Level Measurement______________________________________________________ When a Northeast chemical manufacturer needed reliable level measurement of their transfer tanks, they turned to Flowline. The firm manufacturers water-based resins, adhesives and polymers that are delivered in tanker trucks or IBC totes. The chemicals are sticky, vaporous and often foaming when agitated. Tanker loads are transferred to the fill station and dispensed into trucks. The operator complained that previous ultrasonic level sensors became erratic during and shortly after the pump process, and they needed reliable measurement and spill prevention. For these reasons, Flowline suggested our radar sensors that are unaffected by the process and a high-level pump shut off. The radar sensors provide reliable level data to the PLC, which monitors the tanks and controls the fill station. Flowline is reliable level measurement. |

Water Remediation Tank Guided Wave Level Measurement______________________________________________________ When an Arizona copper mine company needed reliable level measurement of their groundwater remediation tanks, they turned to Flowline. The now dormant mine once processed copper oxide ore with sulfuric acid. Today, it’s an environmental clean-up project focused on the past wastewater, leach and evaporation pond sites. Groundwater is pumped into a filter and neutralization system that recirculates between two tanks. The operator said that past pressure level sensors had failed due to corrosion and clogging, and they needed reliable level measurement. For these reasons, Flowline suggested our 316 stainless guided wave sensors that are unaffected by clogging particulates. The guided wave sensors provide reliable level data to the PLC, which monitors the tanks and controls the remediation process. Flowline is reliable level measurement. |

Diesel Boiler Storage Tank Radar Level Measurement_________________________________________________________________ When a Midwest aerospace company needed reliable level measurement of their boiler diesel storage tanks, they turned to Flowline. Each boiler room has a 300-gallon tank that’s refilled via tanker truck delivery. The truck fill stations are 1-2 stories above and 75-150 feet away from the tanks. Each station has a 0-100% level indicator that the driver uses to monitor the fill process. The maintenance staff said that the previous ultrasonic level sensors became unstable during tank filling due to foam and this had caused delivery problems. For this reason, Flowline suggested our intrinsically safe radar sensors that are unaffected by foam. The radar sensors provide reliable level data to the fill station indicators and building SCADA. Flowline is reliable level measurement. |

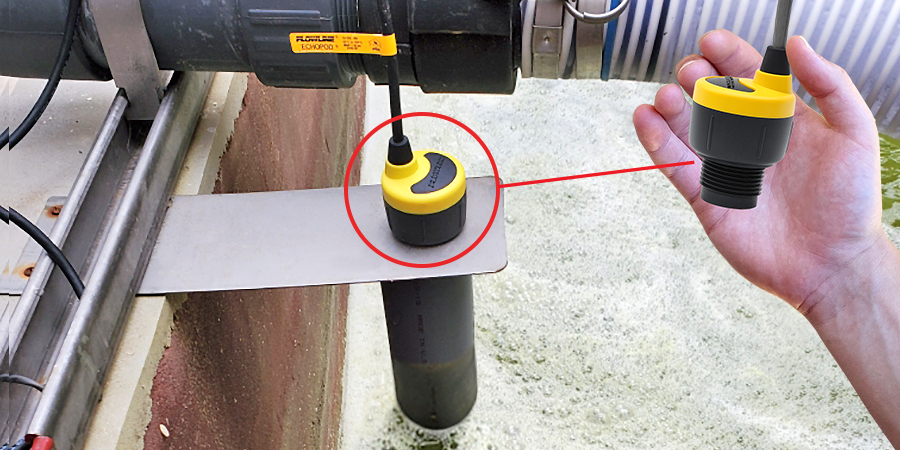

Foaming Small Tank Ultrasonic Level Measurement_________________________________________________________________ When US manufacturers need reliable non-contact level measurement of their foaming small tank skid or machine systems, they turn to Flowline. Foam is sometimes created by mixer and pump processes. Foam attenuates acoustic energy and may cause ultrasonic level sensors to function erratically. But the benefits of non-contact measurement and cost are often still desirable. Where so, the solution is to install your ultrasonic sensor in a standpipe, which separates the measurement from foam or agitation for a reliable, stable output. Despite the foam, The ultrasonic sensor provides reliable level data to the machine or skid PLC. Flowline is reliable level measurement. |

Reliable Sodium Hypochlorite Ultrasonic Level Measurement_________________________________________________________________ When a New Mexico water park needed reliable level measurement of their sodium hypochlorite bulk storage tank, they turned to Flowline. Water dissinfection is a critical ongoing function. On a busy day, the park injects 2 gallons of bleach for every 1,000 gallons of water in their attractions, pools and rivers. In peak season, they consume about 2,500 gallons of diluted bleach per month and running out is not an option. The operator said that another ultrasonic level sensor brand became erratic during the twice daily condensation cycles in the tank, and this caused nuisance alarms. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides reliable level data to the SCADA for monitoring and replenishment. Flowline is reliable level measurement. |

Reliable Sodium Hydroxide Ultrasonic Level Measurement_________________________________________________________________ When a Midwest water treatment plant needed reliable level measurement of their new sodium hydroxide storage tank, they turned to Flowline. The city transitioned their main water supply to a different lake and installed a pump booster station to transport the water 3.5 miles to the plant. At the station, they begin the water treatment process by steadily injecting sodium hydroxide. As caustic is corrosive and highly coating, the plant operator wanted reliable non-contact level measurement with a local display and alarms for the chemical truck driver to monitor during tank refill. For this reason, Burns & McDonnell specified our reflective ultrasonic level sensor, level controller and NEMA enclosure with alarm indicators. The ultrasonic sensor provides reliable level data to the SCADA system and local display. Flowline is reliable level measurement. |

Farm Fertigation Chemical Tank Ultrasonic Level Measurement_________________________________________________________________ When a California central valley farm coop needed reliable level measurement of their chemical bulk storage tanks, they turned to Flowline. The coop blends and dispenses fertilizers and pesticide for the surrounding farm members. The operator had no level measurement, couldn’t see through the black tanks, and hired an integrator to install level indication with alarms in the office. The integrator required reliable, corrosion resistant non-contact level measurement with a signal distance greater than 300′. For this reason, Flowline suggested our ultrasonic level sensors with a PVDF transducer and 80º temperature rating for outdoor installation on the scalding hot black tanks. The ultrasonic sensor provides reliable level data to the PLC and multi-channel display. Flowline is reliable level measurement. |

Reliable Polymer Powder Silo Level Measurement_________________________________________________________________ When an Indiana municipality needed reliable level measurement of their polymer silo, they turned to Flowline. Prior to water disinfection and filtration, the plant steadily mixes and adds polymer slurry to the sewage for improved flocculation and reduced clarification time. The operator said that the past bob-type mechanical level sensor was susceptible to clogging, it required ongoing maintenance and they wanted a non-contact level solution. For these reasons, Flowline suggested our non-contact radar sensors that provide reliable and maintenance-free level measurement of polymer silos. They also installed our ultrasonic sensors in their polymer batch make up tanks to automate the process. The radar sensor provides reliable level data to the SCADA which alarms for silo replenishment. Flowline is reliable level measurement. |