Diesel Generator Tank Guided Wave Level Measurement______________________________________________________________________

When a Nevada municipality needed reliable level measurement of their emergency diesel generator fuel storage tanks, they turned to Flowline. Located outside the water plant, a pump lift station transfers sewage from adjacent communities to the plant for treatment. With the power grid under stress, plant operators installed two larger diesel storage tanks which doubled their generator run time. The system integrator contacted Flowline and requested a metal, high accuracy level sensor with the ability to output in gallons. For these reasons, Flowline suggested our stainless-steel guided wave sensor and WebCal configuration software that linearizes the output for tank shape and volume. The guided wave sensors provide reliable level data to the SCADA which monitors the tanks and alarms for fuel replenishment. Flowline is reliable level measurement. |

Aluminum Sulfate Bulk Tank Ultrasonic Level Measurement______________________________________________________________________

When a Kentucky municipality needed reliable level measurement of their aluminum sulfate bulk storage tanks, they turned to Flowline. During the hot summer months, blooms of harmful blue algae grow in lakes and reservoirs. To combat it, they utilize spray boats that apply aluminum sulfate, a powerful flocculant that safely removes blue algae. Prior to dispatch, boats are trailered to a bulk tank, where they fill up the IBC spray tank with chemical. The operator complained that past ultrasonic level sensors became intermittent during peak humidity, and this resulted in untimely chemical shortages when they needed it most. Based on this, Flowline suggested our reflective ultrasonic sensors that are unaffected by humidity and the daily condensation cycles in the tank. The ultrasonic sensors provide reliable level data to the SCADA, which monitors the bulk tanks and alarms for alum replenishment. Flowline is reliable level measurement. |

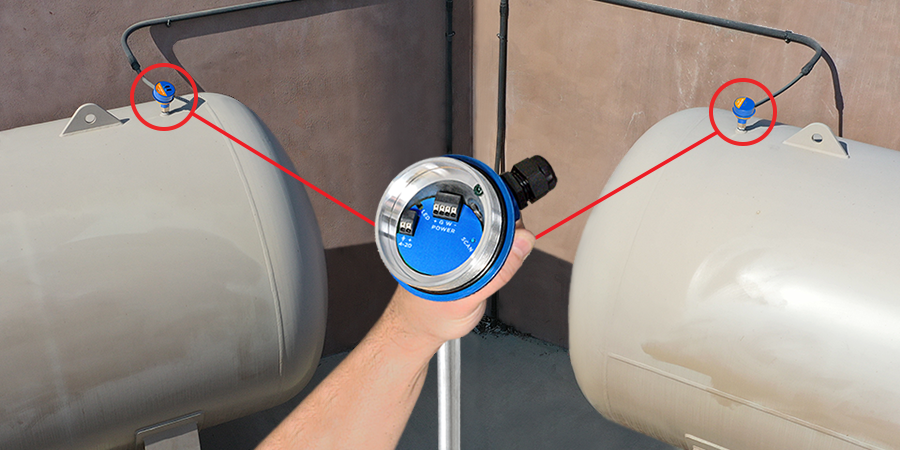

Gas Compressor Station Tank Ultrasonic Level Measurement ______________________________________________________________

When a Texas oil company needed reliable level measurement of their compressor station storage tanks, they turned to Flowline. Travel a natural gas pipeline and about every 50 miles or so, you’ll find a compressor station. The stations scrub, filter and push the gas down the next pipe section on its way to market. These systems consume a lot of glycol, scavenger, diesel and lubricating oils, and require frequent replenishment. The firm was dissatisfied with the high cost of previous radar level sensors, and needed a reliable, low cost, non-contact level sensor that can be applied in hazardous locations. For these reasons, Flowline suggested our intrinsically safe reflective ultrasonic sensors. The ultrasonic sensors provide reliable level data to the SCADA, which monitors the bulk tanks and alarms for replenishment. Flowline is reliable level measurement. |

Reliable Sewer Pump Station Radar Level Measurement ______________________________________________________

When a Gulf Coast municipality needed reliable level measurement of their sewer pump stations, they turned to Flowline. As the operator explained, the water department struggled with level problems here for decades. Twenty years ago, they replaced sticking floats with non-contact ultrasonic sensors. Then a few years later, tired of condensation and foam-based intermittency, they replaced ultrasonic with pressure sensors. Then they faced a learned choice, “Either we suspend them for easy removal and cleaning, and agitation damages them, or we affix them to the bottom, and have to send a man down there to clean them when they clog.” That was two years ago. Since then, they’ve deployed twelve reliable and maintenance-free Flowline radar sensors and are very satisfied. The radar sensors provide reliable level data to the panel mount display and SCADA, which monitors the stations and controls the pumps. Flowline is reliable level measurement. |

Plating Ultrapure Water Tank Ultrasonic Level Measurement______________________________________________________________________

When a Midwest metal finishing company needed reliable level measurement of their ultrapure water storage tanks, they turned to Flowline. The firm specializes in gold plating RF connectors for defense and medical equipment manufacturers. The finish tolerances are tight and their process requires steady replenishment of ultrapure water. The operator was dissatisfied with past ultrasonic level sensors that became intermittent during the twice daily condensation cycles in the tanks and caused downtime. For this reason, Flowline suggested our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks and controls their refill from the RO system. Flowline is reliable level measurement. |

SOFI Diesel Generator Tank Guided Wave Level Measurement______________________________________________________________

When SOFI Stadium needed reliable level measurement of their diesel generator tanks, they turned to Flowline. During a city power loss, three CAT generators immediately turn on, maintaining stadium and broadcast power for NFL games. At the front of each generator is a 58-gallon day tank pump system that automatically transfers fuel from the bulk storage tank to the generators. The pump control is level based and the stadium operators required absolute reliability, 12V battery operation and a rugged metal enclosure. For these reasons, Flowline suggested our guided wave level sensors that are ideal for diesel tank systems. The guided wave sensors provide reliable level data to the PLC, which monitors the day tanks and controls the transfer pumps. Flowline is reliable level measurement. |

Soda & Calcium Carbonate Silo Radar Level Measurement______________________________________________________________

When an East Coast glass manufacturer needed reliable level measurement of their solid’s storage silos, they turned to Flowline. Glass is comprised of silica, soda ash and calcium carbonate, and these materials are inventoried in nine silos. At the base of each silo are double hoppers that dispense to conveyors that feed production. There the plant operator stated that the past bob type mechanical level sensors would often entangle with the hopper structures and were deemed unreliable. Hence his team had to regularly climb the silos to verify the levels and un-stick the sensors. For this reason, Flowline suggested our non-contact radar sensors with narrow beams that reliably measure well into the hoppers. Upon successful test and validation, eight more radar sensors were installed. The radar sensors provide reliable level data to the indicators, which display the inventories and alarm for replenishment. Flowline is reliable level measurement. |

Golf Water Reclamation Tank Ultrasonic Level Measurement______________________________________________________________

When a Palm Desert golf course needed reliable level measurement of their greywater reclamation tanks, they turned to Flowline. The course has four fairway bathrooms and one snack bar kitchen to serve members during a round. The sinks drain to sumps which then transfer filtered greywater to two hillside bulk storage tanks. From there, the water gravity feeds back to the toilets for flushing. If the tanks are full, the sump pumps are disabled, and the greywater is diverted to sewer overflow pipes. Maintenance stated that the past ultrasonic level sensors became erratic during the condensation cycles in the tanks, and members were naturally irate when the toilets ran out of out of water. For this reason, Flowline suggested our proprietary reflective ultrasonic level sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the SCADA system, which monitors the tanks and controls the pumps. Flowline is reliable level measurement. |

Waste Recycling Tank Radar & Ultrasonic Level Measurement______________________________________________________________

When an East Coast recycling company needed reliable level measurement of their waste storage and treatment tanks, they turned to Flowline. The firm transports, treats and safely disposes of liquid waste from manufacturing firms. Waste enters the facility in tanker trucks and is pumped into storage tanks. Then depending on type and classification, the waste is pumped into one of several treatment tank processes. Once treated, the waste is briefly stored and then disposed of in an appropriate way. Level measurement is imperative to the operation, and the facility needed to update their sensors. For this reason, Flowline suggested radar sensors in the foaming or vaporous storage and treatment tanks, and ultrasonic sensors in the non-foaming chemical storage and treated wastewater tanks. The level sensors provide reliable level data to the PLC, which monitors the tanks and controls the process. Flowline is reliable level measurement. |

University Boiler Tank Guided Wave Level Measurement______________________________________________________________

When a Midwest university needed reliable level measurement of their boiler tanks, they turned to Flowline. The boilers heat, pump and recirculate hot water throughout the basketball stadium, team locker rooms and training facility. The boilers were initially installed with a metal high & low level float switch mounted in the external standpipe. The switches failed every two years due to scaling or corrosion and required replacement. The issue then became lead time which averaged six weeks. Fed up, the maintenance manager said, “That’s an eternity. We need a reliable, corrosion resistant level sensor that mounts in a standpipe and is unaffected by scaling. Additionally, we want to display the gallons and set alarms.” For these reasons, Flowline suggested our guided wave sensor and level controller. The guided wave sensor provides reliable level data to the indicator, which actuates the alarms and repeats the 4-20 mA signal to the building management system. Flowline is reliable level measurement. |