Caustic Soda Storage Tank Radar Level Measurement_________________________________________________________________

When a Midwest chemical distributor needed reliable level measurement of their caustic bulk storage tank, they turned to Flowline. From which, the company fills and delivers IBC tote and drum containers of sodium hydroxide to their clients. Caustic soda foams when agitated, which often occurs during transfer from one tank to another. Each month, the storage tank is refilled via a rail tanker car delivery. During which, plant operators complained that previous ultrasonic level sensors became and remained unreliable, until the foam dissipated. For this reason, Flowline suggest our radar sensors that are unaffected by foam, vapor or corrosive media. The radar sensor provides reliable level data to the controller, which indicates the caustic inventory and alarms for replenishment. Flowline is reliable level measurement. |

Municipal Chemical Feed Tank Ultrasonic Level Measurement_________________________________________________________________

When a Virginia water treatment plant needed reliable level measurement of their chemical feed tanks, they turned to Flowline. The plant injects sodium permanganate and manganese sulfate in their drinking water filtration process for taste and odor control. These purple and red-brown oxidizers have the viscosity of ink and are notoriously harsh on fluid handling equipment and sensors. The operators complained that previous float level switches were unreliable, as they would stick due to coating and eventually fail due to corrosion. For this reason, Flowline suggested our non-contact ultrasonic sensors that are ideal for coating and corrosive chemicals. The ultrasonic sensors provide reliable level data to the SCADA, which monitors the inventories and alarms for replenishment. Flowline is reliable level measurement. |

Sewer Pump Lift Station Radar Level Measurement_________________________________________________________________

When a Texas municipality needed reliable level measurement of their sewer pump stations, they turned to Flowline. These waste receptacles are laden with water, feces, paper, trash, detergents and oil that coat everything it touches. Following a costly overflow, the city council requested a failure analysis and preventative action recommendation from the water department. Not surprisingly, it was determined that the float level switches had stuck through a combination of material build up due to coating and entanglement due to turbulence. For this reason, Flowline suggested our non-contact radar sensor that’s easy to install, maintenance free and intrinsically safe for methane gas. The radar sensors provide reliable level data to the SCADA system, which monitors the stations and controls the pumps. Flowline is reliable level measurement. |

Waste Oil Reclamation Tank Ultrasonic Level Measurement_________________________________________________________________

When a Carolina oil reclamation company needed reliable level measurement of their storage and process tanks, they turned to Flowline. The firm bulk transports, stores, filters and refines waste cooking oil and grease into biofuel for resale. The media is extremely coating, their hot process tanks are located in a hazardous area, and the system integrator required non-contact level sensors. For these reasons, Flowline suggested our ultrasonic sensors in the ambient tanks, and intrinsically safe radar sensors in the hazardous process tanks. Eighteen sensors provide reliable level data to the telemetry system, which monitors the tanks and uploads the data to the enterprise system for truck and production management. Flowline is reliable level measurement. |

Barge Fuel And Lube Tank Radar Level Measurement_________________________________________________________________

When a Tennessee barge transportation company needed reliable level measurement of their holding tanks, they turned to Flowline. The firm transports crude, diesel, process oils, lubricants and asphalt between terminal locations and customers up and down the Mississippi river. Barge scheduling and logistics is optimized through tank level inventory monitoring and a satellite based telemetry system. The liquids are hazardous, vaporous, sticky and agitated when underway, and the operations team wanted non-contact level measurement. For these reasons, Flowline suggested our intrinsically safe radar sensors that reliably measure petroleum media, independent of such variables. The radar sensors provide reliable level data to the telemetry system, which uploads to the operations center. Flowline is reliable level measurement. |

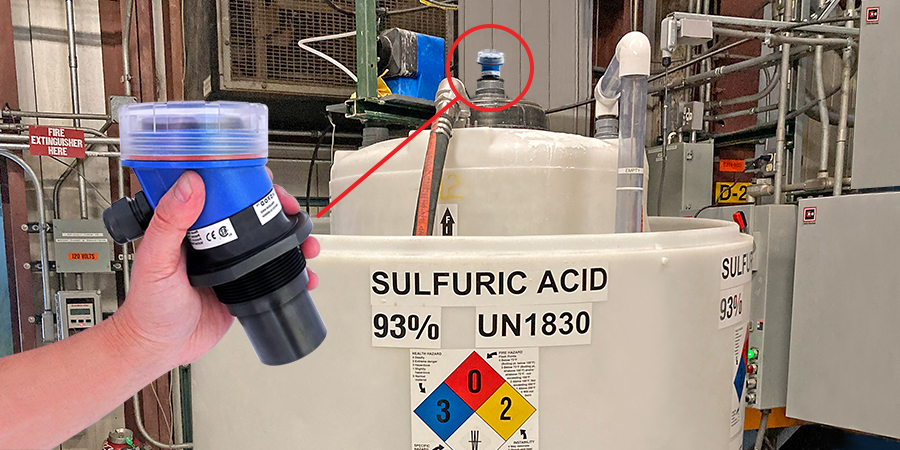

Lab Sulfuric Acid Feed Tank Ultrasonic Level Measurement_________________________________________________________________

When a US government test lab needed reliable level measurement of their sulfuric acid chemical storage and feed stations, they turned to Flowline. The laboratory explores the forces that govern our universe, and highly concentrated sulfuric acid is applied in their processes. While the tanks are inside, the delivery truck filling apparatus are outside. This would have required truck operators to hook up, start the pump and go inside to monitor the fill, which was unacceptable. The system integrator choose Flowline, and we suggested our non-contact and fully corrosion resistant, ultrasonic level sensors. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks and alarms at the outside filling stations. Flowline is reliable level measurement. |

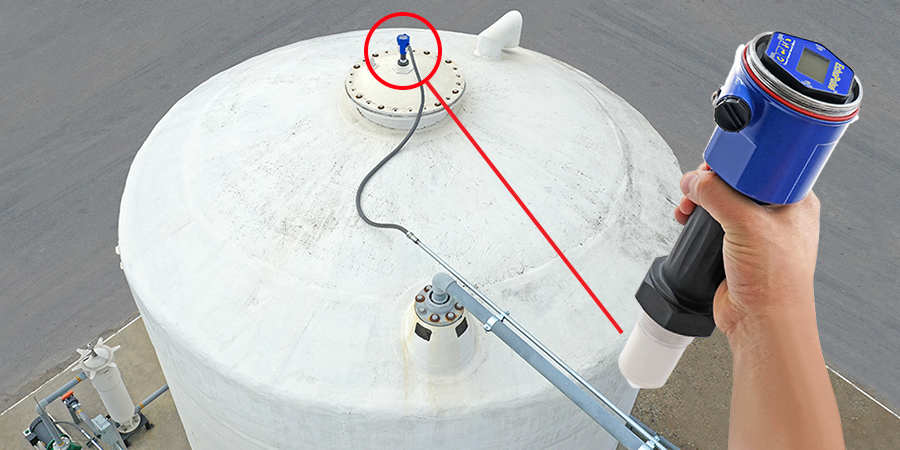

Asphalt Slurry Seal Bulk Tank Radar Level Measurement_________________________________________________________________

When an Idaho road contractor needed reliable level measurement of their asphalt slurry storage tanks, they turned to Flowline. The firm repairs, resurfaces and seals streets, parking lots and runways from three site locations. Each has an equipment yard with a heated slurry tank that’s refilled weekly by their supplier. But as business fluctuates, the deliveries sometimes don’t coincide with demand. Couple that with employee hesitancy to climb ladders and look down into a near boiling, vaporous caldron, and it’s not surprising they were incurring costly product outages. For this reason, Flowline suggested our non-contact radar level sensors that are unaffected by fluctuations in temperature, vapor or media. The operator has since received a lower insurance premium. The radar sensors provide reliable level data to the displays, which monitor the tanks and alarm for replenishment. Flowline is reliable level measurement. |

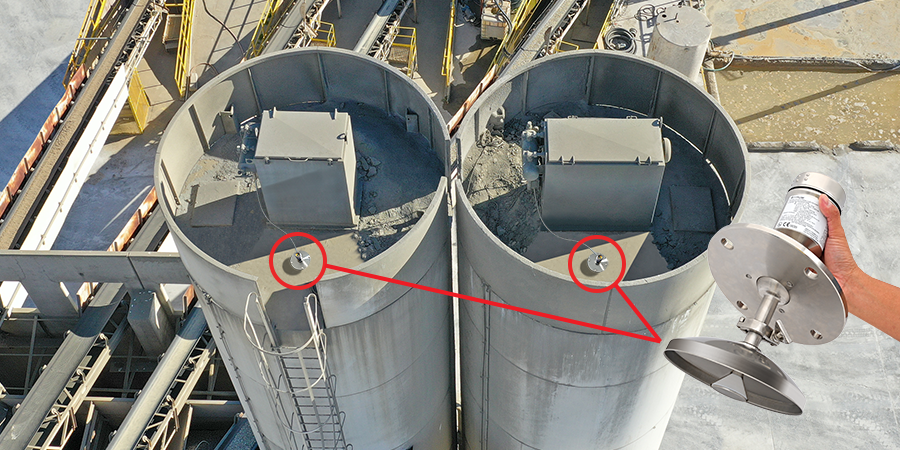

Concrete Batch Mix Plant Silo Radar Level Measurement_________________________________________________________________

When a Minnesota concrete mix plant needed reliable level measurement of their cement silos, they turned to Flowline. The firm crushes, batches, mixes and delivers wet concrete to contractor sites throughout greater Minneapolis. A concrete batch is comprised of 40% gravel, 30% sand, 20% water and 10% cement or the binding agent that glues everything together. Cement powder is periodically delivered and stored in silos. There the operators were dissatisfied with previous mechanical type level sensors that often clogged with powder and hardened cement fragments that had reacted with condensation. For this reason, Flowline suggested our non-contact radar sensors with high power antennas that are unaffected by buildup. The radar sensors provide reliable level data to the PLC, which monitors the cement silos, and alarms for replenishment. Flowline is reliable level measurement. |

Diesel Tank Remote Monitoring Ultrasonic Level Measurement_________________________________________________________________

When an Arizona petrol distributor needed reliable level measurement of their portable diesel storage tanks, they turned to Flowline. The company provides construction, highway, mine and quarry customers with onsite deliveries of fuel, lube and DEF for trucks and heavy equipment. The tanks frequently have no power or connectivity and are normally in place for 1-12 months before being moved to a new site. Without field tank inventory data, customer fuel outages, urgent deliveries or trucks returning with partial loads is inevitable. Frustrated, the operators contracted with a telemetry provider, who selected Flowline ultrasonic level sensors for reliability. Once a day, the solar powered telemetry unit, turns on the ultrasonic sensor, and uploads level data to the operators web page for visibility. Flowline is reliable level measurement. |

Water Tower Tank Guided Wave Level Measurement_________________________________________________________________

When a Utah heavy equipment rental company needed reliable level measurement of their water tower trailer tanks, they turned to Flowline. The 12,000 gallon tanks are deployed at earth moving sites, where dust clouds, agitated neighbors and dust fines are an ongoing concern. To address this, water trucks work in concert with the earth moving equipment to spray and tamp down the dust. When not spraying, they drive between the tanks and closest fire hydrant to replenish their supply. The operator explained that each move costs fuel and time, and may not be necessary, based on the tanks inventory status. They needed a better way. For this reason, Flowline suggested our guided wave level sensor , display and enclosure. Now a supervisor can drive up, plug the display into his pickup AC port, verify status, and radio for water replenishment when needed. Flowline is reliable level measurement. |