Water Level Monitoring and Alarming System on Floating Walkway in Jurong Lake________________________________________________________________________________________________

|

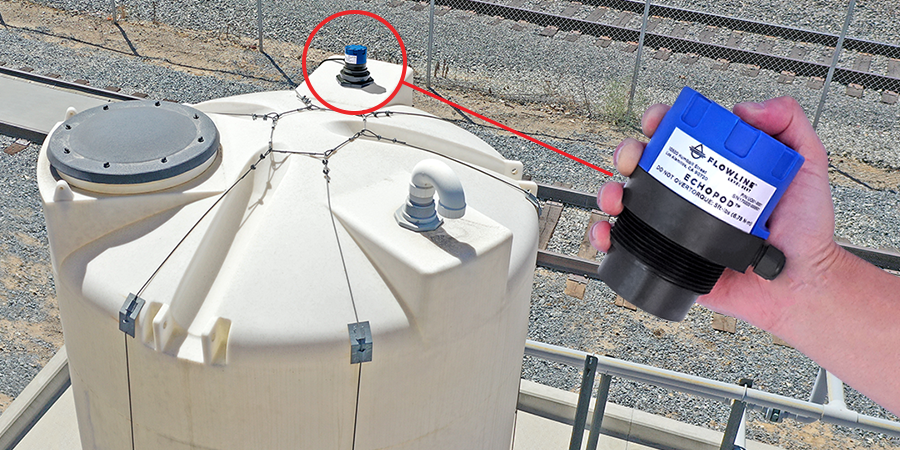

Neutralization Chem-Feed Tank Ultrasonic Level Measurement__________________________________________________________________________________________

When a California almond farm company needed reliable level measurement of their sulfuric acid chemical feed tanks, they turned to Flowline. As the continued drought forces Central Valley growers to dig deeper wells, their mineral composition changes and often requires treatment. For example, this farm recently pushed into a high pH aquifer, and now they inject sulfuric acid into the distribution pipes exiting each well. The operator, who ran out of chemical several times, then contracted with an integrator to install a long range WIFI monitoring system. With so, the integrator needed a reliable, corrosion resistant level sensor, that’s compatible with each chemical and designed for outdoor use. For this reason, Flowline suggested our reflective ultrasonic sensor. The ultrasonic sensor provides reliable level data to the WIFI system which transmits the inventory status to their operations center. Flowline is reliable level measurement. |

Chemical Batch Mix Tank Ultrasonic Level Measurement______________________________________________________________________________________

When a New Jersey chemical distributor needed reliable level measurement of their mixing tanks, they turned to Flowline. The company packages and delivers water treatment chemicals to industrial, commercial and municipal clients throughout the Northeast. These are typically customer specific dilutions of chemical and water for their application needs. The batches are made in two mix stations that are manually filled, blended and dispensed into IBC’s or drums. The operators were using a gallon line indicator inside the tank to visually gauge the water to chemical fill ratio, and they wanted to improve accuracy and speed. For this reason, Flowline suggested our accurate ultrasonic level sensors and bright tank indicators. The ultrasonic sensors provide reliable data to the station indicators which display the gallons filled in each mix tank. Flowline is reliable level measurement. |

Plastic Pellet Silo And Bin Radar Level Measurement________________________________________________________________

When a Kansas bottle manufacturer needed reliable level measurement of their HDPE silos, they turned to Flowline. The firm produces plastic containers for motor oil, lubricant, chemical and fertilizer companies. The bottles are made in blow molding machines that convert plastic pellets into containers using heat, pressure, air and water. With the cost of plastic rising, the company shifted to a lower cost supplier of recycled plastic chips. The ground chips are of varying size and shape with burred edges, and they often attach to one another forming clumps. This made the surface topography uneven, which further scattered the acoustic signals, and caused their past ultrasonic level sensors to function intermittently as the level dropped low in the silos. For this reason, Flowline suggested our radar sensors that are unaffected by the surface characteristics of the media. The radar sensors provide reliable level data to the PLC, which monitors the silos and alarms for plastic chip replenishment. Flowline is reliable level measurement. |

Wastewater Storage Tank Radar Level Measurement________________________________________________________________

When a Mississippi food processing company needed reliable level measurement of their bulk wastewater storage tanks, they turned to Flowline. The firm processes vegetable products for private label customers that they wash, cut, package and ship to restaurants and grocery stores throughout the state. Upon receipt, the vegetables are soaked in disinfectant baths and thoroughly spray washed to remove any pollutants. The resulting wastewater is collected and pumped into three storage tanks awaiting monthly pick up and disposal via railcar. The operator complained that the waste stream often foams as it enters the tanks, which caused the previous ultrasonic level sensors to measure intermittently during and after pump transfer. For this reason, Flowline suggested our radar sensors that are unaffected by process variables like foam. The radar sensors provide reliable level data to the PLC, which monitors the tanks and controls the pumps. Flowline is reliable level measurement. |

Greywater Bulk Storage Tank Ultrasonic Level Measurement________________________________________________________________

When a California campground needed reliable level measurement of their greywater storage tank, they turned to Flowline. Each rental cabin has its own sink and shower with guests utilizing common men’s or ladies rooms for toilets. Suffering through the drought, the camp wells are far less productive, and the trend is not sustainable. To address this, the operator installed a greywater system that collects, filters and treats the sink and shower water for reuse in flushing toilets. One month later, the system integrator contacted Flowline stating that the previous ultrasonic level sensor functioned intermittently during the twice daily condensation cycles within the tank. For this reason, Flowline suggested our proprietary reflective ultrasonic sensor that’s unaffected by condensation. The ultrasonic sensor provides reliable level data to the PLC, which monitors the storage tank and gravity feeds the toilets. Flowline is reliable level measurement. |

Municipal Sewer Lift Station Radar Level Measurement________________________________________________________________

When a Gulf Coast wastewater treatment plant needed reliable level measurement of their sewer pump lift stations, they turned to Flowline. These human waste receptacles are notoriously hard on sensors and pumps, as they contain feces, paper, grease, chemicals, particulates and trash. Plant operators had used pressure level sensors for years, but were tired of the high costs of downhole maintenance. As one said, “If we hang them from the top, the pump turbulence damages them. If we affix them to the bottom, we have to go down there to install and maintain them with a confined space team.” For these reasons, Flowline suggested our non-contact radar sensors that are easily installed at the top for maintenance-free operation. The radar sensors provide reliable level data to the SCADA for pump control and sensor display for convenient level indication. Flowline is reliable level measurement. |

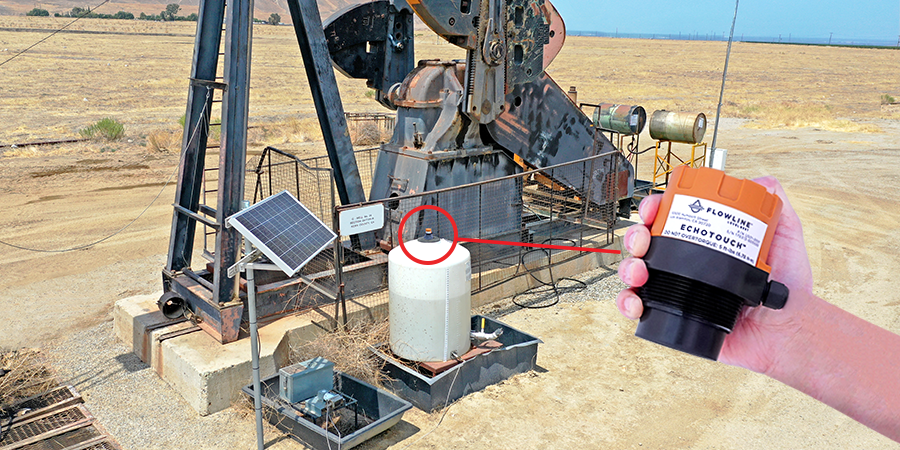

Pump Jack Chem-Feed Tank Ultrasonic Level Measurement______________________________________________________________________

When a California oil company needed reliable level measurement of their pump jack chemical feed tanks, they turned to Flowline. To maximize well production and minimize equipment failures, chemicals such as descalers, corrosion inhibitors and surfactants are commonly injected. As many wells are in remote locations and they operate at different rates, replenishing the tanks is typically enabled through level measurement and telemetry. The operator complained that past ultrasonic level sensors became intermittent during the frequent condensation cycle inside tank. For this reason, Flowline suggested our award winning reflective ultrasonic sensors that are unaffected by condensation. The intrinsically safe ultrasonic sensors provide reliable level data to the radio telemetry unit, which alarms for chemical truck replenishment. Flowline is reliable level measurement. |

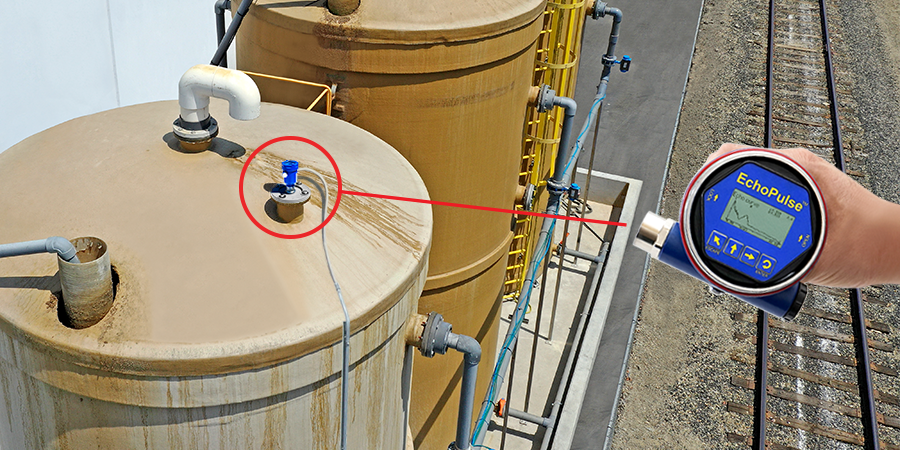

Lube Oil Transfer Tank Ultrasonic Level Measurement______________________________________________________________________

When an Alabama lubrication company needed reliable level measurement of their rail transfer tanks, they turned to Flowline. The firm custom blends and packages engine, hydraulic, turbine, compressor and gear oils for private label clients. They receive bulk oil deliveries from rail cars that are offloaded to transfer tanks, which in turn fill the production bulk tanks in the facility. The operator stated that the past pressure level sensors were unable to measure below 8% of the transfer tanks capacity. As a result, the staff would frequently short the tank transfer process, and occasionally run a pump dry, costing them either way. For this reason, Flowline suggested our ultrasonic sensors that measure the transferable capacity of the tank. The ultrasonic sensors provide reliable level data to the operator display, which indicates the tank levels. Flowline is reliable level measurement. |

Truck Stop DEF Tank Ultrasonic Level Measurement______________________________________________________________________

When a Missouri truck stop needed reliable level measurement of their DEF bulk storage tank, they turned to Flowline. The full-service station provides everything the trucking community needs including diesel exhaust fluid at the pump. A corrosive mix of urea and water, DEF is harsh to many metals and elastomeric seals. The operator said that the past pressure level sensor was replaced twice in a year due to leakage. They wanted a reliable, corrosion resistance level sensor that can be safely installed in a hazardous area. For these reasons, Flowline suggested our non-contact and intrinsically safe ultrasonic sensor. The ultrasonic sensor provides reliable level data to the operators in-store display, which indicates the DEF level. Flowline is reliable level measurement. |