Tower Diesel Generator Tank Guided Wave Level Measurement________________________________________________________________

When a Washington state wireless carrier needed reliable level measurement of their tower backup diesel generators, they turned to Flowline. Select towers are mission critical and they are integrated with gensets for continuous service. The gensets auto-run once a month to verify their operational status and the diesel tank level is then transmitted over the network to the fuel supplier. The system integrator said that the prior hinged mechanical float level sensors were susceptible to locking up when the temperature dipped below freezing, and this had caused reporting errors. For this reason, Flowline suggested our solid-state guided wave sensors that are ideal for diesel and are unaffected by temperature variations. The guided wave sensor provides reliable level data to the tower SCADA which uploads the data for fuel replenishment. Flowline is reliable level measurement. |

Cooling Water Intake Channel Radar Level Measurement________________________________________________________________

When an East Coast power station needed reliable level measurement of their water intake channel, they turned to Flowline. The thermoelectric plant generates tremendous heat and consumes vast amounts of water in its cooling processes. The channel supplies the station with ocean water and the level is monitored for tide and storm surges. The operator stated that the previous ultrasonic level sensor became intermittent during extreme weather events, just when they needed it most. For this reason, Flowline suggested our radar sensors that are unaffected by wind, rain or snow, and designed for easy bracket mount installation. The radar sensors provide reliable level data to the SCADA which monitors the channel and alarms during storm surges. Flowline is reliable level measurement. |

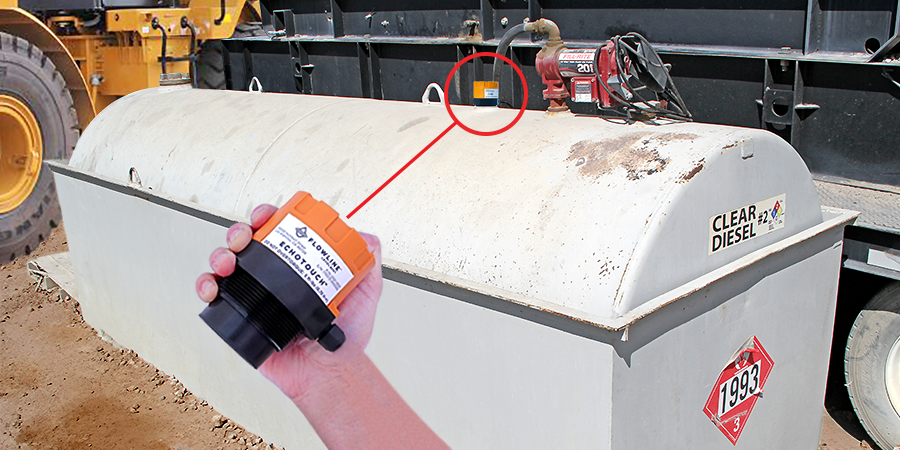

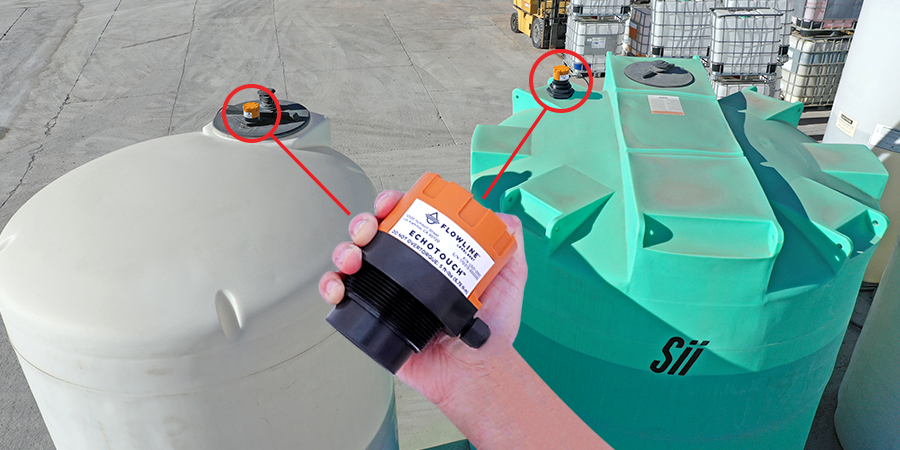

Diesel Generator Fuel Tank Ultrasonic Level Measurement________________________________________________________________

When a Midwest heavy equipment construction company needed reliable level measurement of their portable diesel storage tanks, they turned to Flowline. The firm deploys field operation centers and infrastructure to support their road and sewer projects. The centers are powered by generators and each site is data linked over long range WIFI. The system integrator explained that fuel outages had caused painful downtime. The site operators wanted to replace the pop-up level indicators with continuous measurement and push the data for proactive inventory management. For insurance compliance, they also needed intrinsic safety. For these reasons, Flowline suggested our EchoTouch ultrasonic level sensor. The ultrasonic sensors provide reliable level data to their headquarters which monitors inventories and dispatches truck replenishment. Flowline is reliable level measurement. |

Concrete Admixture Tank Ultrasonic Level Measurement________________________________________________________________

When a Florida concrete company needed reliable level measurement of their chemical storage tanks, they turned to Flowline. The plant custom blends and delivers concrete to construction sites across the state. During make up, chemical additives are introduced to enhance the workability, hardness and durability of each batch. These widely range from acids to surfactants or color compounds to polymers. The operator stated that past pressure level sensors were susceptible to clogging and corrosion, and he wanted one level sensor that could be reliably used across all chemicals with a display user interface. For this reason, Flowline suggested our non-contact ultrasonic sensor. The ultrasonic sensors provide reliable level data to the PLC, which monitors the chemical inventory and alarms for replenishment. Flowline is reliable level measurement. |

Adhesive Bulk Storage Tank Radar Level Measurement________________________________________________________________

When a Southeast adhesive manufacturer needed reliable level measurement of their customer bulk storage tanks, they turned to Flowline. They supply hot melts, glues and resins to furniture and building material manufacturers. As the chemicals are quite viscous, they’re transported, stored and dispensed at elevated temperature. The operator stated that past pressure level sensors failed due to clogging and ultrasonic level sensors failed due to vapor attenuation. He also wanted an indicator that the driver could monitor during tank filling with a high and low-level alarm. For these reasons, Flowline suggested our non-contact radar sensor that’s unaffected by vapor, packaged with a controller. The radar sensor provides reliable level data to the controller, which displays gallons and actuates alarms. Flowline is reliable level measurement. |

EchoPulse® LR15 Radar Liquid Level Sensor Transmitter________________________________________________________________

The general purpose 26 GHz. pulse radar level transmitter provides continuous level measurement up to 98.4’ (30m) with a 4-20 mA signal output, and is configured via its integral push button display module. The non-contact liquid level sensor is intended for petroleum, water, wastewater and diluted chemical storage or process applications in above or below grade tanks of any material. Select this sensor for challenging process conditions with diluted or non-corrosive media, light surface foam or agitation, higher temperature or pressure, condensation or vapor, and installation in a tank adapter, flange fitting or metal stand-pipe. Typical applications include bulk storage, tanker truck, process tank, waste sump and neutralization tanks. |

Chemical Distributor Tank Ultrasonic Level Measurement______________________________________________________________________________________ When an Ohio chemical distributor needed reliable level measurement of their chemical bulk storage tanks, they turned to Flowline. The firm blends, packages and delivers cleaning and sanitization chemicals to food and beverage manufacturers. Bulk chemicals are offloaded via railcar to eight storage tanks that feed their production vessels. The operator stated that previous pressure level sensors failed within six months due to corrosion, and this had caused product outages. Additionally, the tanks were near flammable liquids, and they required intrinsic safety. For these reasons, Flowline suggested our non-contact and intrinsically safe ultrasonic level sensors. The ultrasonic sensors provide reliable data to the PLC, which monitors the chemical inventories and alarms for replenishment. Flowline is reliable level measurement. |

Municipal Chemical Storage Tank Radar Level Measurement________________________________________________________________ When a Missouri municipality needed reliable level measurement of their chemical bulk storage tanks, they turned to Flowline. The water treatment plant uses considerable amounts of sulfuric acid, sodium hydroxide and ferric chloride in their process. The chemicals are corrosive, crystalizing, foaming or coating, and difficult to measure. To simplify use, the operator wanted to standardize on one level sensor that could reliably measure all liquids. For this reason, Flowline suggested our non-contact radar sensor that’s completely unaffected by the liquid characteristics. The radar sensors provide reliable data to the SCADA, which monitors the chemical inventories and alarms for replenishment. Flowline is reliable level measurement. |

Sanitization Chemical Feed Ultrasonic Level Measurement________________________________________________________________ When a Texas poultry processor needed reliable level measurement of their chemical feed system, they turned to Flowline. Food safety is their highest priority and sanitizing chemicals are critical to meat and equipment cleanliness. Collectively they inhibit pathogen growth, eliminate odors, and improve the texture of processed meat. The integrator required reliable, corrosion-resistant level measurement of both foaming and non-foaming type chemicals. For these reasons, Flowline suggested our non-contact ultrasonic sensors for the non-foaming chemicals, and radar sensors for the foaming chemicals. The ultrasonic and radar sensors provide reliable level data to the telemetry units, which monitor the inventories and alarm for replenishment. Flowline is reliable level measurement. |

Wastewater Storage Tank Ultrasonic Level Measurement________________________________________________________________ When a California trucking company needed reliable level measurement of their wastewater tank, they turned to Flowline. The firm performs regular maintenance at their fleet service center. Every week, the bay floors are power washed into a sump which pumps the wastewater to a storage tank for bi-monthly offsite removal and treatment. The water contains residual fuel oil, DEF, coolant, grease and hazardous vapor. The operator wanted a non-contact level sensor and a remote display with alarms for placement in the service center. For these reasons, Flowline suggested our intrinsically safe ultrasonic sensor and indicator package with two configurable relay alarms. The ultrasonic sensor provides reliable level data to the indicator, which displays in percent full and alarms for truck pick up. Flowline is reliable level measurement. |