Corrosive Acid Storage Tank Radar Level Measurement______________________________________________________________

When an East Coast glass manufacturer needed reliable level measurement of their solid’s storage silos, they turned to Flowline. Glass is comprised of silica, soda ash and calcium carbonate, and these materials are inventoried in nine silos. At the base of each silo are double hoppers that dispense to conveyors that feed production. There the plant operator stated that the past bob type mechanical level sensors would often entangle with the hopper structures and were deemed unreliable. Hence his team had to regularly climb the silos to verify the levels and un-stick the sensors. For this reason, Flowline suggested our non-contact radar sensors with narrow beams that reliably measure well into the hoppers. Upon successful test and validation, eight more radar sensors were installed. The radar sensors provide reliable level data to the indicators, which display the inventories and alarm for replenishment. Flowline is reliable level measurement. |

Resin Plastic Pellet Silo Radar Level Measurement ______________________________________________________ When an East Coast plastics manufacturer needed reliable level measurement of their resin pellet silos, they turned to Flowline. The company produces high quality plastic components for pharmaceutical packaging and medical machine applications. Recent supply chain delays exposed the need for improved pellet inventory data, purchase and production planning. The operator required six level sensors capable of measuring up to 65′ for connection to a multi-channel display at their rail loading dock. For this reason, Flowline suggested our solids radar sensors with rotational flanges for easy mounting and aiming. The radar sensors provide reliable level data to the indicator, which monitors the silos and alarms for pellet replenishment. Flowline is reliable level measurement. |

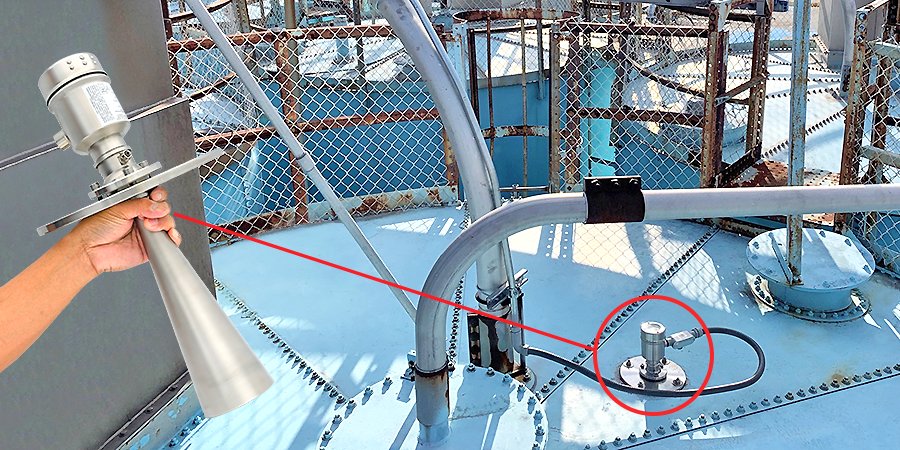

Shipyard Wastewater Sump Radar Level Measurement _________________________________________________________________ When a West Coast shipyard needed reliable level measurement of their waste pump lift stations, they turned to Flowline. The firm provides maintenance services to small freighters, commercial fishing vessels and workboats. The sounds of banging, grinding, welding, sanding and painting fills the space, as an array of residual material falls to the ground. A vacuum truck sweeps the yard daily, but it doesn’t get it all. Rain and periodic wash downs, push what’s left into sumps that transfer the waste into treatment. There the operator complained that past ultrasonic level sensors were unreliable after wash downs, when foaming chemicals entered the pits. For this reason, Flowline suggested our radar sensors that are unaffected by foam, condensation or turbulence. The radar sensors radar sensors provide reliable level data to the PLC, which monitors the sumps and controls the waste transfer process. Flowline is reliable level measurement. |

Corrosive Wastewater Tank Ultrasonic Level Measurement________________________________________________________________

When a Midwest steel products manufacturer needed reliable level measurement of their corrosive waste water storage tanks, they turned to Flowline. The company manufacturers metallic storage systems, racks and shelving for residential and commercial applications. Prior to metal finishing, the parts are dipped in diluted hydrochloric acid baths to remove particulate, oil or grease. To maintain finish quality, the HCI dip and rinse baths are frequently recycled with the corrosive waste sent to treatment. There the operator complained that previous ultrasonic level sensors became intermittent during the twice daily condensation cycles in the tank. For this reason, Flowline suggested our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks and controls the treatment process. Flowline is reliable level measurement. |

Settling Basin Water Tank Guided Wave Level Measurement________________________________________________________________

When a California municipality needed reliable level measurement of their basin water tank, they turned to Flowline. Adjacent to mountains, muddy water and plant debris pass through the culvert to a settling basin. Before and after a major rain, the basin is typically excavated with heavy equipment. The location is remote, there’s no power or water, and the potential for fire is high. A water tank sits 250 feet above the site, and gravity feeds back to the basin for equipment cleaning or fire mitigation. The city required a rugged metal level sensor that would work with a portable 12V battery powered display box that they could use to check the level, and when necessary, dispatch a water tanker. For this reason, Flowline suggested our guided wave sensor that’s ideal for metallic tank applications. The guided wave sensor provides reliable level data to the battery powered display. Flowline is reliable level measurement. |

Bottle Filling Machine Tank Ultrasonic Level Measurement________________________________________________________________

When a North Carolina equipment manufacturer needed reliable level measurement of their filling machine batch tank, they turned to Flowline. Their client bottles and distributes high purity chemicals to pharmaceutical research labs and universities. The batch tank receives, blends and dispenses chemicals into twenty one liter bottles per batch. Initial tests revealed that the originally specified ultrasonic level sensor became intermittent when condensation developed in the tank. For this reason, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides reliable level data to the PLC which controls the batch make up and filling. Flowline is reliable level measurement. |

Water Plant Vault Lift Station Radar Level Measurement________________________________________________________________

When a West Coast water treatment plant needed reliable level measurement of their stormwater intake vault, they turned to Flowline. Stormwater first enters the plant in a deep rectangular vault with three pumps that transfer the water into the treatment process. During peak inflow, the vault is agitated and often has surface foam. The plant operator said that the previous ultrasonic level sensor became unstable whenever foam migrated under the sensor, and a stand-pipe installation was not desirable due to turbulence. For this reason, Flowline suggested our radar sensors that are unaffected by media characteristics such as agitation, foam and mist. The radar sensor provides reliable level data to the SCADA which monitors the vault and triplex controls the pumps. Flowline is reliable level measurement. |

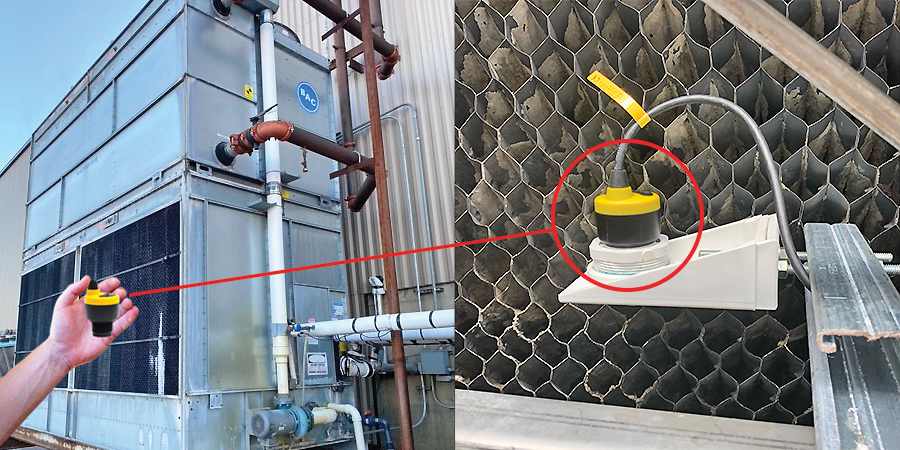

Cooling Tower Water Sump Ultrasonic Level Measurement________________________________________________________________

When a Midwest commercial HVAC maintenance contractor needed reliable level measurement of their clients cooling tower sumps, they turned to Flowline. Under continual evaporation, cooling towers require frequent water replenishment, and the most common associated failure is a corroded or scaled float or conductance level sensor. To fix this, the contractor required a non-contact level sensor that can be used as a switch with relay contacts or a transmitter with an analog output, thus enabling them to replace any maintenance configuration they encounter. For these reasons, Flowline suggested our multi-function ultrasonic sensors that are perfectly applied in small sumps. The ultrasonic sensor provides reliable level data to the controller that monitors the sumps and controls the fill valves. Flowline is reliable level measurement. |

Fertigation Storage Tank Ultrasonic Level Measurement________________________________________________________________

When a California avocado farmer needed reliable level measurement of their liquid fertilizer storage tanks, they turned to Flowline. Located in remote Northeast San Diego County, the farm has two wells and automated drip irrigation. To increase fruit vigor and yield, the trees require nitrogen and zinc throughout the grow season. So, they mix, store and inject liquid fertilizers at each well site. Given their locale, the chemical delivery cost is high and must be scheduled well in advance. The farm manager said that the previous float level switches would corrode and fail every six months, resulting in fertilizer outages. He needed a reliable level switch that would alarm at 50% and 25% of tank capacity. For these reasons, Flowline suggested our non-contact, corrosion resistant ultrasonic sensors with integral relays and control logic. The ultrasonic sensors provide reliable switching to the wireless SCADA that transmits alarms to the farm shop. Flowline is reliable level measurement. |

Water Remediation Tank Guided Wave Level Measurement________________________________________________________________

When a California remediation company needed reliable level measurement of their water storage tanks, they turned to Flowline. Their client, a golf course design and construction company, needed to remove organic pollutants from the groundwater of a former winery. To do so, well water is pumped through a carbon filtration system and returned to the aquifer. A pressurized storage tank buffers the inconsistent flow through the system which runs 24/7. The operator needed to protect the pump by measuring the level and shutting it down if it drops, a sign of air ingestion. For this reason, Flowline suggested our guided wave level sensors that are ideal for pressurized tank applications. The guided wave sensor provides reliable level data to the level controller which shuts down the pump. Flowline is reliable level measurement. |