Landfill Remediation Tank Ultrasonic Level Measurement_________________________________________________________________

When a Nevada landfill needed reliable level measurement of their wastewater remediation bulk storage tanks, they turned to Flowline. Built deep into a hillside, compacted trash layers are covered in dirt and isolated from the ground environment with a network of plastic lined containment cells. Seeping liquid and stormwater runoff drain from the cells to sumps that collect and transfer the waste to three remediation storage tanks. There landfill operators complained that past pressure level sensors clogged, required frequent maintenance, and failed due to corrosion. They added, “We literally get just about everything in these tanks.” For this reason, Flowline suggested our non-contact and corrosion resistant ultrasonic sensors, that are perfect for remediation applications. The ultrasonic sensors provide reliable level data to the SCADA, which alarms for wastewater truck pick up. Flowline is reliable level measurement. |

Sewer Chemical Feed Tank Ultrasonic Level Measurement_________________________________________________________________

When a California municipality needed reliable level measurement of a problematic sewer lift station, they turned to Flowline. Located at the base of a large community, the station had over-flowed and residents complained of an ongoing stench that lofted through their neighborhood. To fix the problem, treatment plant operators decided to replace the failing float switches in the station and inject ferrous sulfate there for odor control. Their system integrator contacted Flowline and we suggested our radar sensor for the sewer station and ultrasonic sensor for the chemical tank. The intrinsically safe radar sensor is unaffected by foam, agitation or methane, and the ultrasonic sensor is ideal for corrosive chemicals. The sensors provide reliable level data to the SCADA, which controls the station pumps and alarms for chemical replenishment. Flowline is reliable level measurement. |

Sodium Hypochlorite Tank Radar Level Measurement_________________________________________________________________

When a New Jersey manufacturer of pulp-based packaging needed reliable level measurement of their bleach storage tank, they turned to Flowline. The firm molds custom drink carriers for Starbucks and egg cartons for Vital Farms. Each starts from recycled paper that’s cleaned, shredded, crushed, and mixed with hot water and bleach to a specified consistency and color. A near continuous process, the company goes through 1-2 bulk tank deliveries of sodium hypochlorite per month. There the plant operators complained that previous ultrasonic level sensors were susceptible to vapor and would often become unreliable as the level dropped in the tank. For this reason, Flowline suggested our PTFE sheathed radar sensors that are unaffected by vapor and ideal for highly corrosive liquids. The radar sensor provides reliable level data to the PLC, which monitors the tank inventory and alarms for chemical replenishment. Flowline is reliable level measurement. |

Reliable Coating Or Scaling Sump Level Control_________________________________________________________________

When a Missouri hospital needed reliable level control of their cooling tower basins, they turned to Flowline. Over time, the hard water builds scaling on everything it contacts, including sump walls and sensors alike. Ultimately, the buildup caused their float valves to fail, basins to evaporate, and HVAC systems to go down for hours. Hospital operators had enough. They wanted to immediately detect and alarm for maintenance during this condition. For this reason, Flowline suggested our Switch-Pak controller with a vibration level switch that’s unaffected by scaling and coating build up. That was ten years ago and here it is, fully scaled and still reliably protecting their HVAC system. The compact controller provides reliable low level water detection and maintenance alarm actuation, with or without scaling. Flowline is reliable level measurement. |

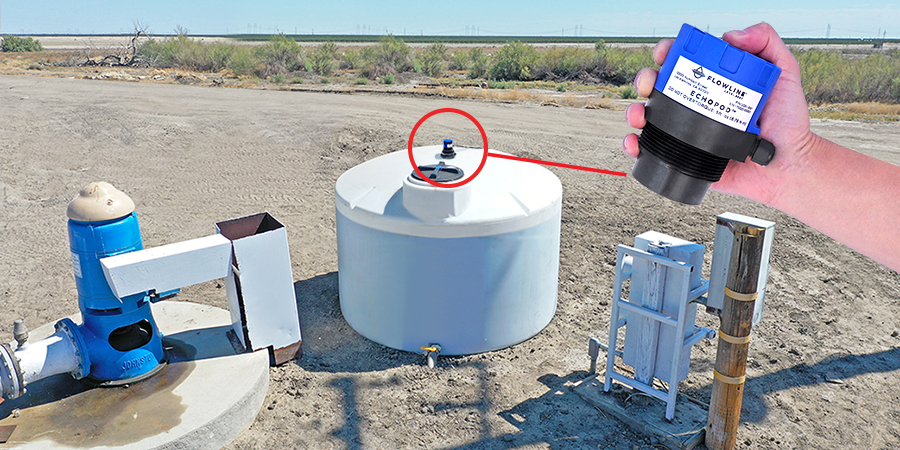

Coffee Wastewater Bulk Tank Ultrasonic Level Measurement_________________________________________________________________

When a California food processor needed reliable level measurement of their wastewater storage tank, they turned to Flowline. The firm cleans roasts, packages and ships coffee beans and grinds to private label customers. A two-day wash and soak process separates the beans outer sticky pulp layer from the inner coffee seed. The resulting waste stream is pumped to a street side storage tank awaiting tanker truck haul away to an offsite treatment facility. There the operators complained that previous pressure level sensors frequently clogged and required ongoing maintenance. For this reason, Flowline suggested our non-contact ultrasonic sensors that are ideal for viscous, coating and scaling wastewater. The ultrasonic sensor provides reliable level data to the PLC, which transfers the waste and alarms for tanker truck pick up. Flowline is reliable level measurement. |

Diesel Distributor Tank Guided Wave Level Measurement_________________________________________________________________

When an Oklahoma fuel and lubricant distributor needed reliable level measurement of their onsite field storage tanks, they turned to Flowline. The company supplies oil field and agriculture heavy equipment operators with diesel fuel and lube oil. Their challenge is efficiency. The driver stops at a customer location, pulls hoses to as many as nine tanks, and returns to the truck to start pumping. But pump how much to where? The driver had to stick each tank, estimate the available capacity, and intensely monitor the filling process, which added up to 30 minutes to each delivery. They needed a better way. For this reason, Flowline suggested the use of our guided wave level sensors installed on each tank with a quick disconnect connector. Now the driver pulls a hose with cable to each tank, connects the cable to the sensor, returns to the truck and turns on power. The guided wave sensors provide continuous level data to a multi-tank display, which reduces delivery time and driver error. Flowline is reliable level measurement. |

Reservoir Dam Gate Spillway Radar Level Measurement_________________________________________________________________

When a Michigan township needed reliable level measurement of their lakeside dam, they turned to Flowline. The reservoir is part of an aging network of smaller dams that manage water retention and flow across the county. During peak rain, the dam can quickly reach maximum capacity, unless the spillway gates are concurrently opened wide up. Last year, a sister dam overflowed and flooded seventy homes to the South. The cause was determined to be an exposed ultrasonic level sensor, which during the storm, had stopped measuring in the extreme rain and wind. City managers said, “Not here”, and instructed their system integrator to install redundant, bullet proof sensors on their dam. Flowline then suggested our radar level sensors, that are specifically designed for outdoor environmental applications. The radar sensors provide reliable level data to the SCADA, which proportionately controls the spillway. Flowline is reliable level measurement. |

Ammonia Gas Diffusion Tank Radar Level Measurement_________________________________________________________________

When a North Carolina meat processor needed reliable level measurement of their ammonia gas diffusion tank, they turned to Flowline. Processed meat is temporarily stored in 35º lockers awaiting transportation. Each has its own refrigeration unit that periodically releases hazardous and corrosive ammonia gas through a pressure relief valve. The gas is collected, pumped through a water diffusion tank, and then safely released to the atmosphere. There plant operators complained that previous metal float switches would corrode and required near annual replacement. They needed reliable, intrinsically safe level control. For these reasons, Flowline suggested our non-contact radar sensors that are corrosion resistant, intrinsically safe and unaffected by vapor within the vessel. The radar sensor provides reliable level data to the PLC, which transfers the waste to treatment and refills the tank. Flowline is reliable level measurement. |

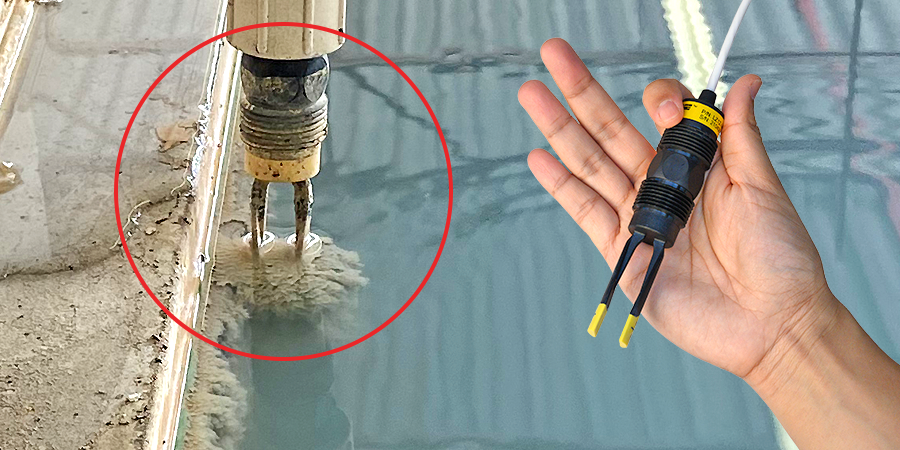

AG Fertigation Chemical Tank Ultrasonic Level Measurement_________________________________________________________________

When a California grower needed reliable level measurement of their fertigation chemical feed tanks, they turned to Flowline. The company grows and sells grapes to large wineries, and this season they replanted 3,000 acres with new seedlings. To establish and sustain rigorous growth, the farmer injects combinations of nitrogen based fertilizers into their irrigation pumping stations. The farmer complained that previous pressure level sensors were not chemically compatible with all fertilizers, and they were done with failures. For this reason, Flowline suggested our reliable, non-contact and corrosion resistant ultrasonic sensors. The ultrasonic sensors provide reliable level data to the telemetry unit, which alarms for chemical truck replenishment. Flowline is reliable level measurement. |

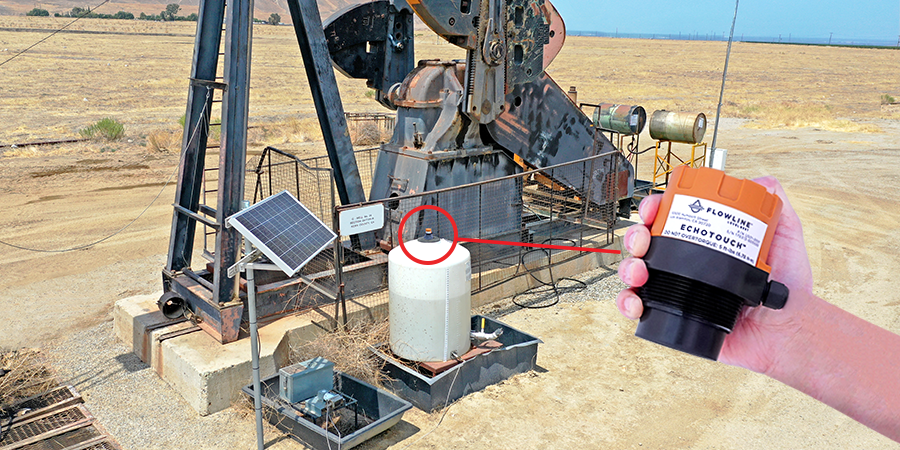

Pump Jack Chemical Tank Ultrasonic Level Measurement_________________________________________________________________

When a California oil company needed reliable level measurement of their pump jack chemical feed tanks, they turned to Flowline. To maximize well production and minimize equipment failures, chemicals such as descalers, corrosion inhibitors and surfactants are commonly injected. As many wells are in remote locations and they operate at different rates, replenishing the tanks is typically enabled through level measurement and telemetry. The operator complained that past ultrasonic level sensors became intermittent during the frequent condensation cycle inside tank. For this reason, Flowline suggested our award winning reflective ultrasonic sensors that are unaffected by condensation. The intrinsically safe ultrasonic sensors provide reliable level data to the radio telemetry unit, which alarms for chemical truck replenishment. Flowline is reliable level measurement. |