Cement Batch Mix Plant Silo Radar Level Measurement_________________________________________________________________

When a Nevada concrete plant needed reliable level measurement of their batch mix silos, they turned to Flowline. The firm supplies ready mix concrete, rock and sand to municipal, residential and commercial customers throughout Las Vegas. Concrete orders are custom batched, blended and delivered via mix truck. During which, water, sand, powders and aggregates are dispensed into batch bins, weighed, mixed and loaded on to trucks. The bulk cement, fly ash and mineral powder inputs are contained in silos. There, operators complained that previous radar level sensors often became intermittent due to antenna powder build up, and required ongoing maintenance. For this reason, Flowline suggested our radar sensors with high power parabolic antennas that are unaffected by buildup, and ideal for cement silo applications. The radar sensors provide reliable level data to the PLC, which monitors the cement silos, and alarms for replenishment. Flowline is reliable level measurement. |

Industrial Wastewater Tank Radar Level Measurement_________________________________________________________________

When a Bay Area coating manufacturer needed reliable level measurement of their wastewater storage tanks, they turned to Flowline. The firm produces thermal ceramic and epoxy coatings for high temperature aircraft, automotive and marine engine parts. Their batch manufacturing process is hot, and their wastewater profile varies based upon the production run. When vapor or foam entered the waste stream, previous ultrasonic level sensors became intermittent due to signal attenuation. For this reason, Flowline suggested our radar sensors that are unaffected by vapor or foam, and are ideal for variable processes. The radar sensors provide reliable level data to the PLC, which monitors the tanks, and controls the waste treatment process. Flowline is reliable level measurement. |

Heavy Equipment Wash Tank Ultrasonic Level Measurement_________________________________________________________________

When an Ohio truck and heavy equipment rental company needed reliable level measurement of their wash system tanks, they turned to Flowline. The firm rents dozers, excavators, loaders and backhoes to construction, oil & gas and mining contractors across the state. Upon return, the equipment is washed, inspected and serviced. Cleaning starts with a two man power wash and each washer is supplied by a recirculating warm water storage tank. There the staff had reliability problems with a different ultrasonic level sensor brand that often became intermittent, due to the attenuating effects of condensation on acoustic signals. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks, and controls the tank refill process. Flowline is reliable level measurement. |

Diesel Generator Tank Guided Wave Level Measurement_________________________________________________________________

When a Las Vegas suburb needed reliable level measurement of their diesel generator storage tanks, they turned to Flowline. Perched above the valley floor, a pump station transfers drinking water from the plant to a hillside reservoir for gravity fed distribution back to the community. During power outages, two diesel generators ensure continued service with each supplied by a 1,000 gallon tank. To verify readiness, once a month the generators are run for one shift, and then inspected. Station operators complained that as the level dropped, previous TDR level sensors became intermittent, bouncing between the actual level and an extreme high alarm. For this reason, Flowline suggested our guided wave sensors that feature disturbance scan mapping, that automatically disregards false signal returns caused by fitting structures. The guided wave sensors provide reliable level data to the SCADA system, which monitors the tanks, and alarms for replenishment. Flowline is reliable level measurement. |

Asphalt Slurry Seal Tank Radar Level Measurement_________________________________________________________________

When a Pennsylvania road contractor needed reliable level measurement of their asphalt slurry seal storage tanks, they turned to Flowline. The firm batches and pumps 500 gallons of slurry from an elevated mix tank to a horizontal storage tank for pump transfer to slurry trucks. The storage tank is heated to 190º F. and slowly blends with internal sweep paddles to maintain consistency. With four locations, the operator wished to centrally monitor inventories to improve purchasing and production. Due to the temperature and coating type media, Flowline suggested our non-contact radar level sensors which detect, map and reject the false reflections off the sweep paddles. The radar sensors provide reliable level data to the display and telemetry unit, which periodically transmits an inventory update. Flowline is reliable level measurement. |

Hydrochloric Acid Bulk Tank Ultrasonic Level Measurement_________________________________________________________________

When a Florida distributor of pool surface cleaning chemicals needed reliable level measurement of their hydrochloric acid storage tank, they turned to Flowline. The firm packages and delivers HCL in one gallon containers to pool supply stores and contractors throughout the state. The HCL is then further diluted and applied to cement, aggregate or stone finishes as an etchant. Based on demand, they require a bulk delivery 1-2 times per month, and reliable level measurement is critical. Plant operators were dissatisfied with a different level sensor brand, whose corrosion based failures had repeatedly caused production downtime. For this reason, Flowline suggested our corrosion resistant and encapsulated non-contact ultrasonic sensors. The ultrasonic sensor provides reliable level data to the controller, which displays the inventory and alarms for replenishment and overfill. Flowline is reliable level measurement. |

Plastic Pellet Storage Silo Radar Level Measurement_________________________________________________________________

When a Midwest manufacturer of plastic bottles and packaging for cosmetic, pharmaceutical and food products, needed reliable level measurement of their pellet storage silos, they turned to Flowline. The firm tools, injects, blow molds and silk screens thousands of bottles per hour for customers across the United States. Pellets of varying materials and colors are received, stored and vacuum transferred to the production floor. Plant operators complained that previous mechanical yo-yo level sensors, that drop and retract weights from the pellet surface, were unreliable, as their mechanical parts would break or jam. For this reason, Flowllne suggested our non-contact radar sensors that provide reliable, maintenance free pellet level measurement. The radar sensors provide reliable level data to the PLC, which monitors the silo inventories and alarms for replenishment. Flowline is reliable level measurement. |

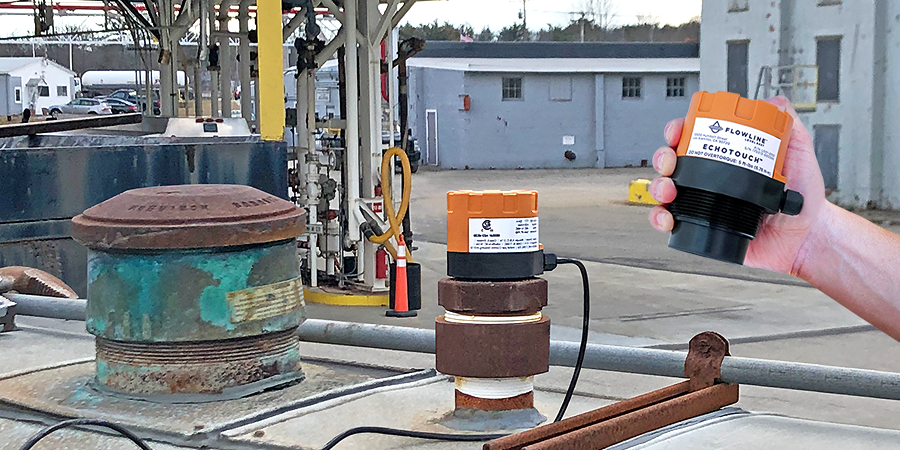

Fuel Distributor Bulk Tank Ultrasonic Level Measurement_________________________________________________________________

When a Northeast fuel distributor needed reliable level measurement of their diesel, bio-fuel, heating oil and additive tanks, they turned to Flowline. The firm receives, stores, blends and delivers energy products to automotive, residential, aviation and marine customers via their terminal distribution centers, and timely fulfillment requires accurate inventory, logistics and weather data. These sticky oil based products are stored in horizontal tanks that previously had mechanical level gauges. The operators complained that the gauges stuck and were unreliable, which forced them to make daily visual tank inspections. For this reason, Flowline suggested our non-contact ultrasonic sensors that are ideal for oil based fuels and lubricants. The intrinsically safe ultrasonic sensors provide reliable level data to the PLC, which monitors the inventories and alarms for replenishment. Flowline is reliable level measurement. |

Reliable Boiler Tank Guided Wave Level Measurement_________________________________________________________________

When a Northeast manufacturer of rubber products needed reliable level measurement of their boiler feed and condensate return tanks, they turned to Flowline. The company produces high pressure hoses that are used in truck and heavy equipment applications. Hoses are hand made on mandrels that roll layers of rubber, fabric, wire and tape to their clients specification. At various production stages, hot water and pressure is applied to cure, release or test the parts. The spent hot water and condensate is then collected and pumped back to the feed tank for recirculation to the boiler. There the operators complained that previous float level switches often failed due to scaling or corrosion. For this reason, Flowline suggested our guided wave sensors that are unaffected by scaling and feature rugged stainless steel antennas. The guided wave sensors provide reliable level data to the PLC, which monitors the feed tanks and supplies the boilers. Flowline is reliable level measurement. |

School Diesel Generator Tank Guided Wave Level Measurement_________________________________________________________________

When New Mexico University needed reliable level measurement of their data center backup diesel generator storage tank, they turned to Flowline. During power outages, the center automatically switches to a battery backup system to maintain server operations. The system is further recharged with a diesel generator that ensures service for up to one week thereafter. To verify readiness, each month the generator is run one shift and inspected. Their diesel supplier was inconsistent in deliveries, and the maintenance team wanted to monitor the tank from their operations center. For this reason, Flowline suggested our guided wave level sensor that accurately and reliably measures diesel. The guided wave sensor provides reliable level data to the SCADA, which monitors the diesel tank and alarms for replenishment. Flowline is reliable level measurement. |