Building Chemical Feed Tank Ultrasonic Level Measurement_________________________________________________________________

When United Technologies in Connecticut needed reliable level measurement of the chemical feed systems supporting their engineering lab facility, they turned to Flowline. With building equipment, processes and critical testing to protect, the water circulating throughout the HVAC, boiler and chiller systems is constantly treated to remove biological pathogens, eliminate scaling and inhibit corrosion. The chemicals are corrosive or coating in nature, and the maintenance team was often replacing or cleaning the previous float level switches. For this reason, Flowline suggested our non-contact PVDF ultrasonic level sensors that provide maintenance free level measurement of chemical feed tanks. The ultrasonic sensors provide reliable level data to the PLC, which monitors the tanks and alarms for chemical replenishment. Flowline is reliable level measurement. |

Foaming Sewer Pump Lift Station Radar Level Measurement_________________________________________________________________

When an Oklahoma municipality needed reliable level measurement of a problematic pump station, they turned to Flowline. Adjacent to a dairy farm, the station was dubbed the “heffahfoamer” by the maintenance team. Once a week, dairy operators deep clean their milking stations using detergent, brushes, disinfectant and power washers. While the wastewater is properly collected and treated prior to release, as it enters the station, the water becomes agitated and it foams for hours. During which, the previous ultrasonic level sensor’s acoustic signal was attenuated by the surface foam, and it remained intermittent until the foam cleared. For this reason, Flowline suggested our robust radar sensors that are unaffected by foam, agitation or vapor. The radar sensor provides reliable level data to the SCADA system, which monitors the station and controls the pumps. Flowline is reliable level measurement. |

Diesel Fueling Station Tank Ultrasonic Level Measurement_________________________________________________________________

When a Colorado truck and heavy equipment company needed reliable level measurement of their diesel fuel stations, they turned to Flowline. The firm contracts with municipalities on road and infrastructure projects that take weeks or months to complete. During which, the efficient ongoing access to fuel is a basic requirement and each project has one or more stations serviced by fuel trucks. After several costly outages, the operators knew they had to replace the manual tank sticking procedure with reliable level automation. For this reason, Flowline suggested our ultrasonic level sensor, display and NEMA enclosure package. The ultrasonic sensor provides reliable level data to the display, which monitors the tank and alarms for diesel replenishment. Flowline is reliable level measurement. |

Reservoir Pump Lift Station Radar Level Measurement_________________________________________________________________

When an Ozark community needed reliable level measurement of their reservoir pumping station, they turned to Flowline. Through which, water is frequently pumped from the Lake of the Ozarks to a small reservoir that feeds the water treatment plant. During heavy rain, the surrounding red clay soil washes into the lake, and the water clouds with particulates that eventually settle to the muddy bottom. Over time, the particulates also enter the pump basin and fill the bottom with fine silt. There, the plant operators grew tired of regularly cleaning pressure level sensors that would otherwise clog, fail and cause problems. Additionally, they wanted a roadside display that would allow them to verify the sensor without exiting their vehicle. For these reasons, Flowline suggested our non-contact radar sensors that come with a field mount indicator. The radar sensor provides reliable level data to the SCADA system, which monitors the basin and controls the pumps. Flowline is reliable level measurement. |

Acid Chemical Feed Tank Ultrasonic Level Measurement_________________________________________________________________

When a Northeast helicopter manufacturer needed reliable level measurement of their acid day tanks, they turned to Flowline. The firm machines, cleans and finishes metal parts to exacting specifications with acids and solvent. The process is supplied by eight, centrally located day tanks that automatically refill from chemical bulk storage. The maintenance team was dissatisfied with previous Teflon level switches that would inevitably corrode in the acids, and force process downtime. They wanted reliable level measurement and intrinsic safety due to the acid tanks proximity to the flammable solvent. For these reasons, Flowline suggested our intrinsically safe, non-contact ultrasonic sensors, connected through Zener barriers in the panel. The ultrasonic sensors provide reliable level data to the PLC, which monitors and refills the acid day tanks. Flowline is reliable level measurement. |

Vaporous Urea Bulk Storage Tank Radar Level Measurement_________________________________________________________________

When a Midwest manufacturer of agricultural and turf chemicals needed reliable level measurement of their urea storage tanks, they turned to Flowline. Urea is widely blended into fertilizer and animal feed products as a safe source of nitrogen that improves crop yields and livestock metabolisms. Operators previously replaced sight glasses with Flowline ultrasonic level sensors on their smaller ammonia and hydrochloric acid tanks, and they wanted to do the same on their taller urea tanks. But urea is exceptionally vaporous, and ultrasonic sensors would not be reliable, due to the vapor’s attenuation of their acoustic signals. For this reason, Flowline suggested the use of our radar sensors with corrosion resistant, PTFE antenna shields that are unaffected by extreme vapor. The radar sensors provide continuous level data to the SCADA system, which monitors the tanks, and alarms for replenishment. Flowline is reliable level measurement. |

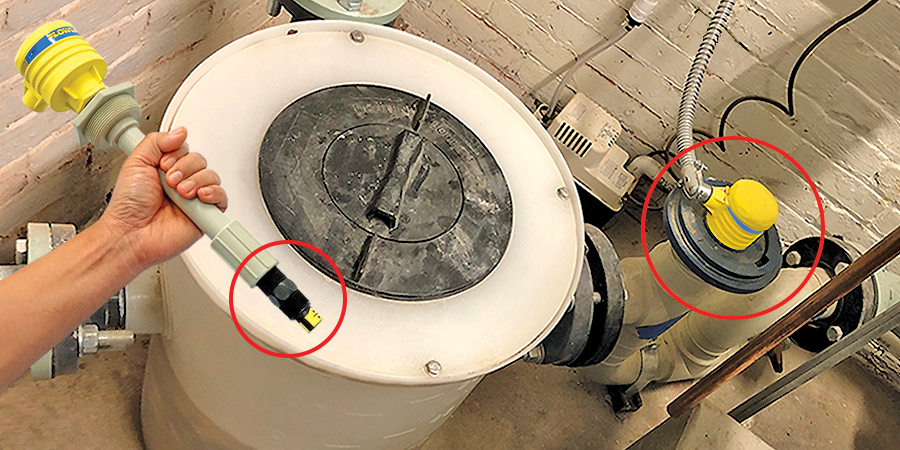

Neutralization Tank Backflow Ultrasonic Level Detection_________________________________________________________________

When Massachusetts Institute of Technology needed reliable backflow detection of their acid wastewater neutralization system, they turned to Flowline. Chemical engineering lab waste drains into small under sink lift stations that sequentially pump the waste to the basement. There the waste enters a limestone chip tank, where it dilutes and neutralizes for two hours, before the next transfer pushes the previously neutralized batch into the sewer. Regulations require a method for detecting backflow in the pipe trap, and the maintenance team wanted strong corrosion resistance. For this reason, Flowline suggested our PP ultrasonic level switch inserted to the base of the outlet pipe. That was nine years ago and its still working reliably. The ultrasonic switch provides reliable level detection to the DCS, which monitors the switch and alarms during backflow. Flowline is reliable level measurement. |

High Tide And Storm Surge Radar Level Measurement_________________________________________________________________

When the peninsula city of Hull, Massachusetts needed reliable level measurement of tidal data, they turned to Flowline. Located at the Southern entrance to Boston Harbor, the low-lying land is susceptible to flooding during astrological high tides or storm surges. Such events are dangerous, and they often result in property damage. The city leaders wanted to install a monitoring system that would detect, measure and alarm during unusually high tides, before they reached flood conditions. In addition, they wanted a level sensing device that could be placed away from the public with a local display for sensor verification. For these reasons, Flowline suggested our radar sensors that are ideal for outdoor environmental applications. When the tide rolls in, the radar sensor provides reliable level data to the SCADA, which monitors the high tide and alarms as necessary. Flowline is reliable level measurement. |

Wrigley Sewer Pump Station Radar Level Measurement_________________________________________________________________

When the city of Chicago, IL needed reliable level measurement of the Wrigley Field sewer pump lift stations, they turned to Flowline. During a game, hundreds of toilets, sinks and concession drains simultaneously flush into nearby lift stations. The inflow rates are significant, and the pumps work non-stop to transfer the waste forward. During which, the waste is agitated, and depending upon contents, may have significant foaming excrement floating on the surface. When so, the field operator was dissatisfied with past ultrasonic level sensors that became erratic due to the attenuation of their acoustic signals. They also expressed concern over the narrow vault and sensor mount location that affords very little measurement space. For these reasons, Flowline suggested our radar sensors with narrow beam widths that are unaffected by floating waste media. The radar sensors provide reliable level data to the SCADA system, which monitors the vaults and controls the pump transfer process. Flowline is reliable level measurement. |

Chemical Tank And Clear Well Ultrasonic Level Measurement_________________________________________________________________

When the Bremerton, WA municipality needed reliable level measurement of their chemical bulk storage tanks and water clear wells, they turned to Flowline. The treatment plant uses sulfuric acid for wastewater neutralization and sodium hypochlorite for drinking water disinfection in their clear wells. To streamline equipment, the operators wanted a single corrosion resistant level sensor that could be applied in both their chemical tanks and clear well stand pipe applications. They also expressed concern over the extreme condensation cycles that exist in the clear well vaults, stating that previous ultrasonic level sensors were often intermittent due to acoustic signal attenuation. For these reasons, Flowline suggested our proprietary reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide reliable level data to the SCADA system, which monitors the tanks and wells, and controls the process. Flowline is reliable level measurement. |