Dairy CIP Chemical Tank Ultrasonic Level Measurement______________________________________________________ When a Wisconsin dairy bottler needed reliable level measurement of their IBC chemical tanks, they turned to Flowline. The dairy utilizes an acetic and octanoic acid organic disinfectant that foams when injected into or on their process equipment. The IBC’s supply the CIP chemicals to their spray systems and each tote is automatically filled from bulk storage. There the engineer had ongoing float level sensor failures due to corrosion and wanted a belt and suspenders level solution. For this reason, Flowline suggested our non-contact ultrasonic sensors for measurement with an adjustable PP Smart Trak for high and low-level alarms. The ultrasonic sensors provide reliable level data to the PLC which controls the IBC refill process. Flowline is reliable level measurement. |

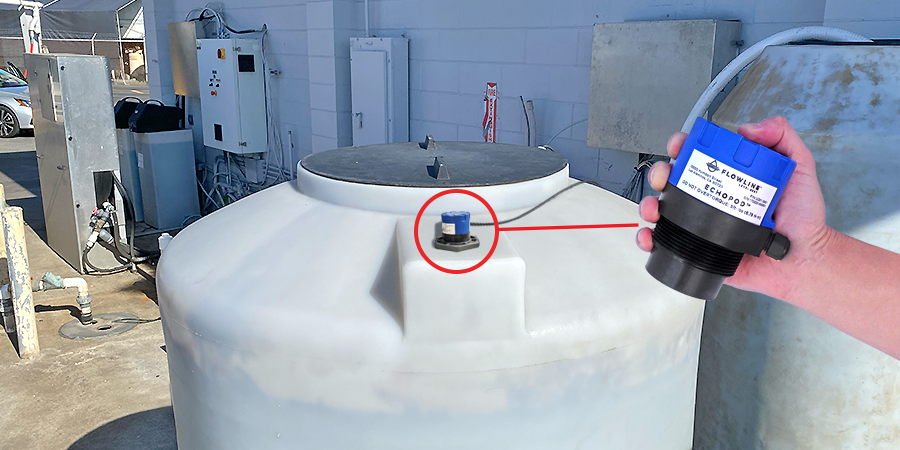

Wastewater Recovery Tank Ultrasonic Level Measurement______________________________________________________ When a Mississippi automobile rental company needed reliable level measurement of their wash wastewater recovery tank, they turned to Flowline. The wash containment bay drains to a sump which pumps its contents through a filter to a holding tank that’s prior to batch treatment and recirculation to the wash bay. There the operator complained that previous pressure level sensors clogged, and float level sensors stuck, and they needed maintenance free level measurement. For this reason, Flowline suggested our non-contact ultrasonic sensors that are ideal for wastewater applications. The ultrasonic sensor provides reliable level data to the PLC which controls the sump and treatment process. Flowline is reliable level measurement. |

Sodium Hypochlorite Storage Tank Radar Level Measurement______________________________________________________ When a Massachusetts water treatment plant needed reliable level measurement of their sodium hypochlorite storage tanks, they turned to Flowline. In higher concentrations or bulk quantities, bleach becomes more vaporous, and as the temperature rises, so does the outgassing. The plant operator said that the previous ultrasonic level sensors worked fine in winter, but became erratic during summer, and they needed reliable non-contact level measurement year-round. For this reason, Flowline suggested our corrosion resistant PFA radar sensors that are unaffected by vapor. The radar sensors provide reliable level data to the SCADA which alarms for bleach refill. Flowline is reliable level measurement. |

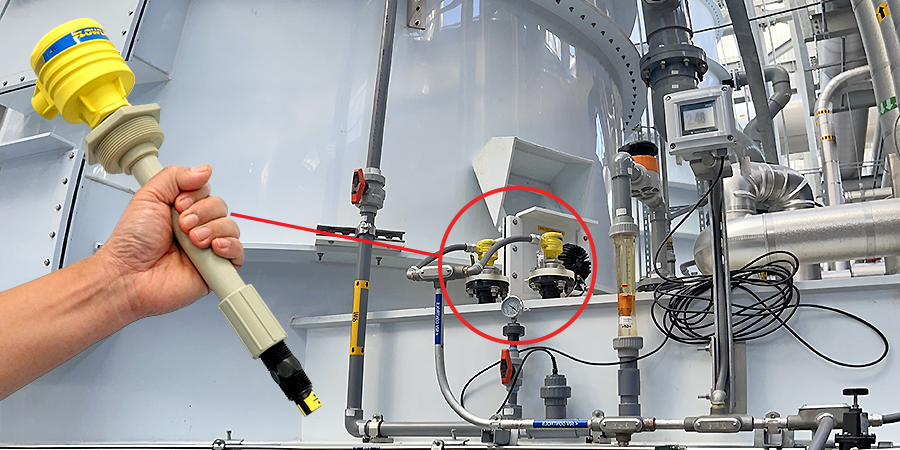

Plating Lift Station Tank Ultrasonic Level Measurement______________________________________________________ When a North American plating system equipment manufacturer needed reliable level measurement of their wastewater transfer station, they turned to Flowline. Plating waste streams are harsh on fluid handling equipment and sensors alike, as they’re hot with suspended solids, grease and diluted acid. The engineer required redundant non-contact level measurement of an enclosed tank with turbulence or condensation, and a separate high-level switch. Each sensor would be tied to a separate pump for redundant transfer to waste treatment. For these reasons, Flowline suggested our ultrasonic level sensors installed in standpipes with a buoyancy level switch mounted under the tank top. The ultrasonic sensors provide reliable level data to the PLC which alternatingly pumps the waste to treatment. Flowline is reliable level measurement. |

Pump Station Diesel Tank Guided Wave Level Measurement______________________________________________________ When a New Mexico water plant needed reliable level measurement of their pump station diesel fuel tank, they turned to Flowline. Located at the base of a large urban valley, the pump station transfers drinking water to hillside storage tanks that supply the community below. A diesel generator provides backup power and is automatically run every other week to ensure readiness. There the operator said that previous float level switches had failed due to coating and caused fuel shortages. They wanted to replace it with a rugged solid state level transmitter that’s unaffected by coating diesel. For this reason, Flowline suggested our guided wave sensors with 316L antennas and a durable aluminum enclosure. The guided wave sensor provides reliable level data to the SCADA which monitors the tank and alarms for fuel replenishment. Flowline is reliable level measurement. |

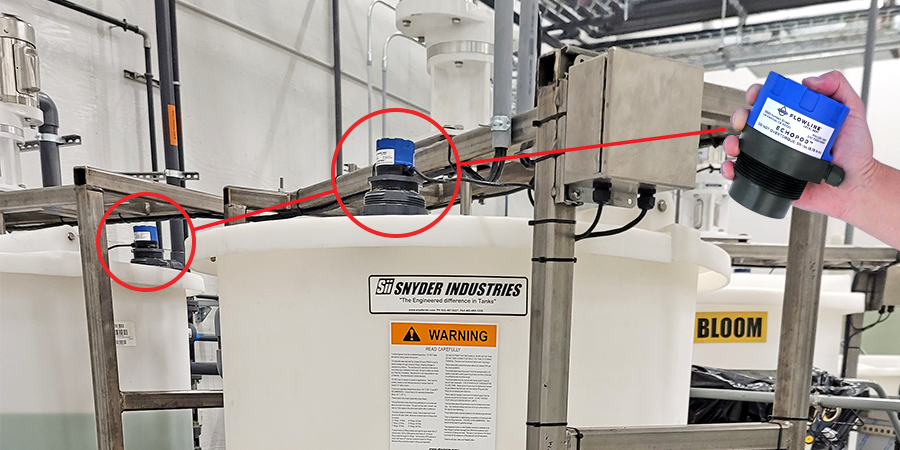

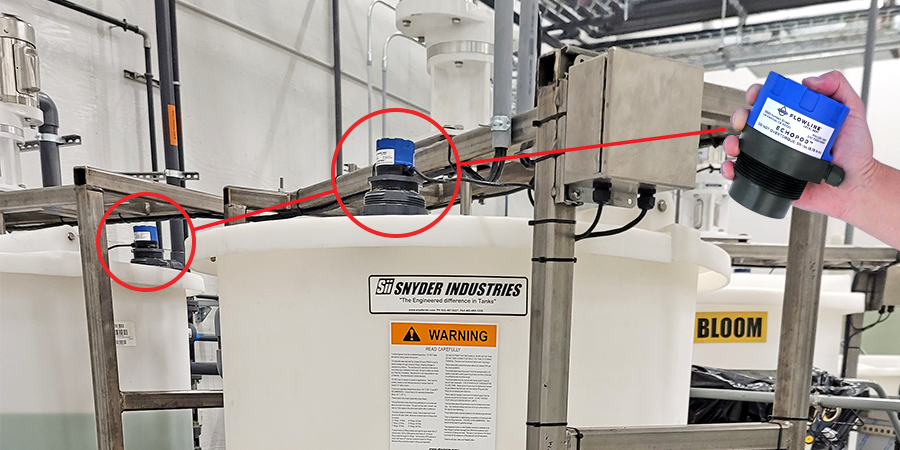

Fertilizer Chemical Mix Tank Ultrasonic Level Measurement______________________________________________________ When a Colorado commercial marijuana grow company needed reliable level measurement of their fertigation mix tanks, they turned to Flowline. From vegetative growth to late bloom flowers, the chemist feeds the plants with an evolving blend of nitrogen, phosphorus, potassium, calcium, sulfur and magnesium to maximize yield and potency. The mix room is the heart of this function where batches are dosed, blended and transferred to individual rooms. There the operator said that previous ultrasonic level sensors were negatively affected by turbulence and their proximity to the blades as they pumped the tank down. For this reason, Flowline suggested our ultrasonic sensors installed in standpipes to dampen any turbulence and separate the acoustic signal from the mixer. The ultrasonic sensors provide reliable level data to the PLC which monitors the tanks during batch filling, mixing and emptying. Flowline is reliable level measurement. |

Reliable Sewer Lift Station Radar Level Measurement______________________________________________________ When an Oregon municipality needed reliable level measurement of their sewer pump lift stations, they turned to Flowline. That was years ago, and it’s still delivering reliable level measurement. At the time, the operator said, float switches coat with grease, pressure gets beat up by pumps, and ultrasonic is susceptible to foam and condensation. We’re tired of false level alarms, maintenance or replacement. We need one sensor that works in this application. For this reason, Flowline suggested our radar level sensors that are unaffected by such variables in the media, process or environment. The radar sensors provide reliable level data to the SCADA that monitors the sumps and controls pump transfer to the plant. Flowline is reliable level measurement. |

Fertilizer Chemical Mix Tank Ultrasonic Level Measurement______________________________________________________ When a Colorado commercial marijuana grow company needed reliable level measurement of their fertigation mix tanks, they turned to Flowline. From vegetative growth to late bloom flowers, the chemist feeds the plants with an evolving blend of nitrogen, phosphorus, potassium, calcium, sulfur and magnesium to maximize yield and potency. The mix room is the heart of this function where batches are dosed, blended and transferred to individual rooms. There the operator said that previous ultrasonic level sensors were negatively affected by turbulence and their proximity to the blades as they pumped the tank down. For this reason, Flowline suggested our ultrasonic sensors installed in standpipes to dampen any turbulence and separate the acoustic signal from the mixer. The ultrasonic sensors provide reliable level data to the PLC which monitors the tanks during batch filling, mixing and emptying. Flowline is reliable level measurement. |

Reliable Scrubber Sump Waste Level Detection______________________________________________________ When a Gulf Coast semiconductor producer needed reliable level detection of their scrubber sumps, they turned to Flowline. Chemicals like silane, phosphine and arsine are used in wafer fabrication, and the resulting hazardous vapor stream must be scrubbed to EPA standards prior to release. The abatement process is constant during manufacturing and managing the scrubber sump levels is critical. The integrator needed a reliable, corrosion resistant level switch that’s unaffected by residual particulates or chemicals. For this reason, Flowline suggested our Switch-Pak single-point ultrasonic level switch that’s ruggedly constructed of corrosion resistant PP. Two ultrasonic switches provide reliable level detection to the PLC, which controls each sump. Flowline is reliable level measurement. |

Diesel Generator Tank TDR Guided Wave Level Measurement______________________________________________________ When a Gulf Coast fuel system equipment supplier needed reliable level measurement of their client’s diesel generator set tanks, they turned to Flowline. Their client is a data center and reliable power is an absolute requirement. Two gensets sit on top of 500-gallon tanks, and each genset is cycled on for 1 hour a week to ensure readiness. The client was tired of cleaning previous float level sensors that inevitably clogged in sticky fuel, and they wanted maintenance free level measurement. For this reason, Flowline suggested our robust guided wave sensors that are unaffected fuel coating. The guided wave sensors provide reliable level data to the PLC which monitors the fuel tanks and alarms for replenishment. Flowline is reliable level measurement. |