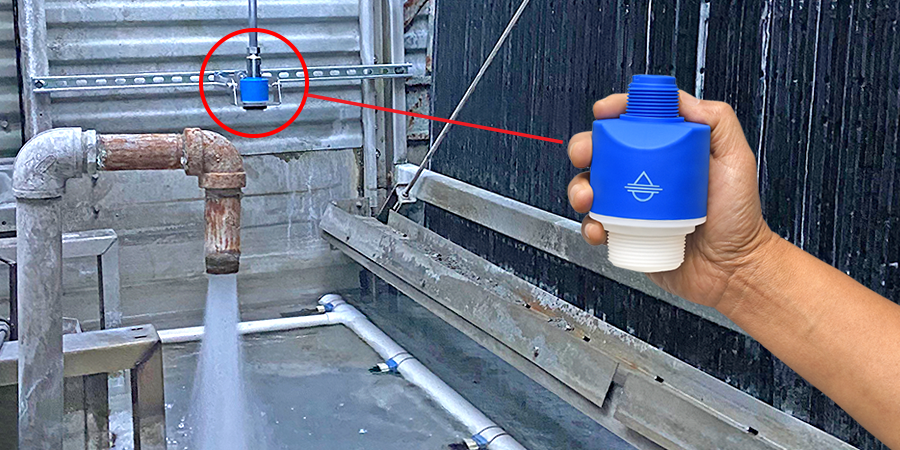

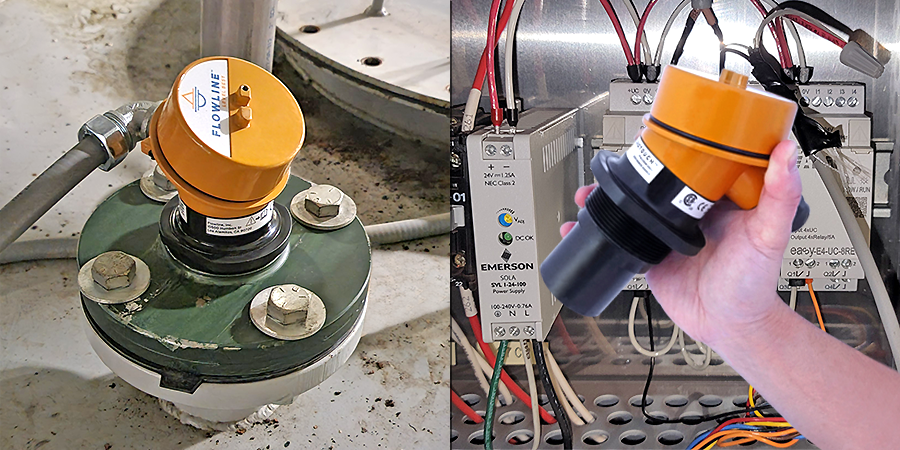

Hospital Cooling Tower Sump Radar Level Transmitter______________________________________________________ When a California hospital needed reliable level measurement of their cooling towers, they turned to Flowline. The regional hospital provides Level-1 trauma, primary, secondary and tertiary services to hundreds of patients a week, and reliable climate control is critical to their healthcare. The facility had experienced several cooling tower outages caused by float switch scaling and corrosion. The engineer wanted to replace the float switches with a reliable non-contact level measurement solution that’s unaffected by agitation, scaling, corrosion or the constant Amazon rains within the towers. For these reasons, Flowline suggested our 80-GHz radar sensors that are easily installed, unaffected by the process and constructed entirely of PVDF. Mounted above each sump, the radar sensors provide reliable level data to the SCADA, which monitors the sumps and actuates their refill. Flowline is reliable level measurement. |

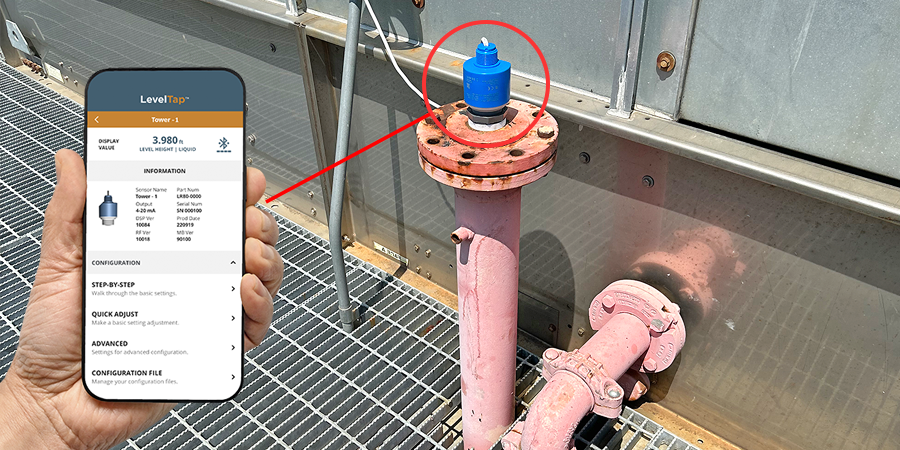

Reduce Ladder Climbs With EchoBeam And LevelTap______________________________________________________ Ask any instrumentation technician, “Name three things you dislike about the job?” Climbing ladders to configure or verify level sensors on tall tanks is always on the list. As one said, “At our facility this requires training, harnessing and a two-man team per our safety procedures. Beyond that, climbing ladders is hard on my body and uncomfortable. In summer, the damn tank tops sizzle at about 130º. That’s why EchoBeam and LevelTap with BLE configuration has made such a difference. Now I climb to install sensors once, and then check them on my phone from the ground or a nearby catwalk. All are write protected and securely accessible by my team members. We’re done with ladders.” LevelTap allows users to wirelessly configure and view the status of paired the EchoBeam radar sensors in the field. Flowline is reliable level measurement. |

Chemical Mini-Bulk Storage Ultrasonic Level Transmitter______________________________________________________ When a Northwest municipality needed reliable level measurement of their lift station chemical storage tanks, they turned to Flowline. Located at the base of a residential community that’s adjacent to homes, the water plant injects disinfection and order control chemicals directly into the station. There the operator required a non-contact and corrosion resistant level measurement solution that’s unaffected by their 90º annual temperature swings and the daily condensation cycles that occur within the tanks. For these reasons, Flowline suggested our PVDF reflective-ultrasonic sensors that automatically shed condensation. The ultrasonic sensors provide reliable level data to the SCADA, which monitors the chemical tanks and alarms for replenishment. Flowline is reliable level measurement. |

Brine Storage Tank Non-Invasive Radar Level Transmitter______________________________________________________ When a Northeast municipality needed reliable level measurement of their brine storage tanks, they turned to Flowline. During winter, anti-icing trucks can be seen dispensing a thin layer of brine on main streets ahead of storms. The trucks are refilled at facilities where brine is made, stored and dispensed. There the city wanted to measure the brine level of each storage tank and indicate their volume outside the pump houses where brine is batch mixed and transferred. Moreover, the tanks had no unused fittings, and they were concerned about their time and ease of installation ahead of fall storms. For this reason, Flowline suggested our 80-GHz radar sensor, installed in our adhesive tank top fitting, connected to our level indicator that’s field mounted in our NEMA box. It doesn’t get any easier. Fast, reliable and cost-effective. The non-invasive radar sensors provide reliable level data to the indicators which display in tank gallons. Flowline is reliable level measurement. |

Train Terminal Oil Tank Radar Level Transmitter______________________________________________________ When a Canadian train terminal company needed reliable level measurement of their facility storage tanks, they turned to Flowline. The firm receives, temporarily stores and transloads liquid products into tanker trucks for delivery. The I&E engineer explained that their operation is tank-centric and reliable level measurement is critical. A common product is cooking oil which requires tank heating and blanketing for efficient pump transfer. There they were dissatisfied with previous contact level sensors that were impacted by material build up and required frequent maintenance. For these reasons, the integrator suggested our non-contact 80-GHz radar level sensors that are simple, accurate, reliable and maintenance-free. The radar sensors provide reliable level data to the PLC which monitors the tanks and controls the terminal. Flowline is reliable level measurement. |

Foaming Wastewater Mix Tank Radar Level Transmitter______________________________________________________ When a Midwest environmental services company needed reliable level measurement of their mixing tanks, they turned to Flowline. The firm transports, treats and safely disposes of wastewater from a wide range of industry sources. Once filtered, the media enters their treatment process starting with large neutralization mix tanks. In which, the media foams during and after agitation. The I&C tech was dissatisfied with prior ultrasonic level sensors that became erratic during foaming, and they needed reliable corrosion resistant level measurement. For these reasons, the integrator suggested our non-contact 80-GHz radar sensors that are unaffected by foam and constructed of PVDF. Problem solved. The radar sensors provide reliable level data to the PLC which monitors the tanks and controls the process. Flowline is reliable level measurement. |

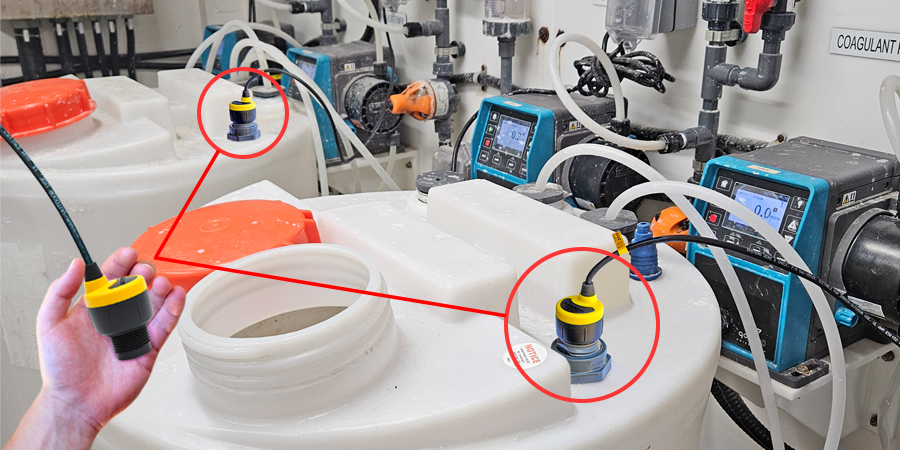

Coagulant Feed Day Tank Ultrasonic Level Transmitter______________________________________________________ When a Southern California municipality needed reliable level measurement of their coagulant day tanks, they turned to Flowline. The treatment plant injects aluminum sulfate as a flocculant to remove chemical phosphorous from inbound waste in their clarifier tanks. This aqueous solution of iron salts is highly corrosive, coating and scaling. The I&E tech said that prior float and conductance level sensors had failed due to coating buildup, and he needed reliable chemical-feed tank level measurement. For these reasons, Flowline suggested our non-contact ultrasonic sensors that are constructed of PVDF and ideal for chemical feed applications. The ultrasonic sensors provide reliable level data to the SCADA system which monitors the tanks and alarms for refill. Flowline is reliable level measurement. |

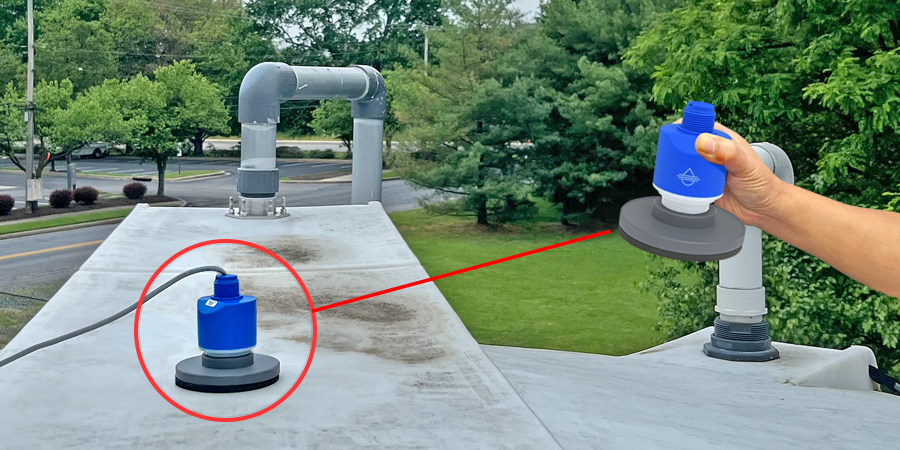

Reliable Cooling Tower Sump Radar Level Transmitter______________________________________________________ When a Midwest chemical manufacturer needed reliable level measurement of their cooling towers, they turned to Flowline. The company refines and supplies nitrogenous fertilizers to agricultural and consumer market resellers. Their manufacturing process operates at high temperatures that are continuously regulated by large cooling towers. The I&C technician explained that the water level of each tower sump is monitored in external stand-pipes, and they were dissatisfied with the reliability of previous ultrasonic level sensors which became erratic during seasonal temperature extremes. For this reason, Flowline suggested our 80-GHz radar sensors that are unaffected by the environment, and ideal for outdoor use in all-weather types. The Bluetooth to App configured radar sensors provide reliable level data to the SCADA, which monitors the towers and controls their refill. Flowline is reliable level measurement. |

Chemical Waste Ultrasonic Level Transmitter______________________________________________________ When a New Jersey pharmaceutical company needed reliable level measurement of their clean in place chemical waste tank, they turned to Flowline. Between production runs, the lines are shut down for cleaning, rinsing and sanitization. Depending on the line, the cleaning chemicals often include sodium hydroxide, nitric acid or hydrochloric acid. During rinse, the chemicals are sprayed off with ultrapure water that drains to a basement storage tank awaiting treatment. There the operator said that past pressure level sensors failed every six months due to corrosion attack and the room was a hazardous area. For these reasons, Flowline suggested our intrinsically safe, non-contact ultrasonic sensors with PVDF transducers that are ideal for corrosive media. The ultrasonic sensor provides reliable level data to the PLC, which monitors the tank and transfers the waste into treatment. Flowline is reliable level measurement. |

Benefits Of Standpipe Ultrasonic Level Transmitter______________________________________________________ When an Ohio system integrator needed reliable level measurement of their customers wastewater and cooling tower sumps, they turned to Flowline. For different reasons, both were problematic. The wastewater was corrosive and foamed up during and after pump transfer, and the tower water was hard, scaling and agitated. In both applications, contact level sensors had limited-service life and were deemed unacceptable. For these reasons, Flowline suggested our non-contact ultrasonic sensors installed in standpipes to dampen the turbulence and isolate foam from the point of measurement. The ultrasonic sensors provide reliable level data to the PLC, which monitors the sumps and controls the pumps and valves. Flowline is reliable level measurement. |